Travelling crane type sewage sludge mixing and propelling machine

A propulsion, traveling-type technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of a large amount of land occupation, large quantity, secondary environmental pollution, etc., and achieve the effect of reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

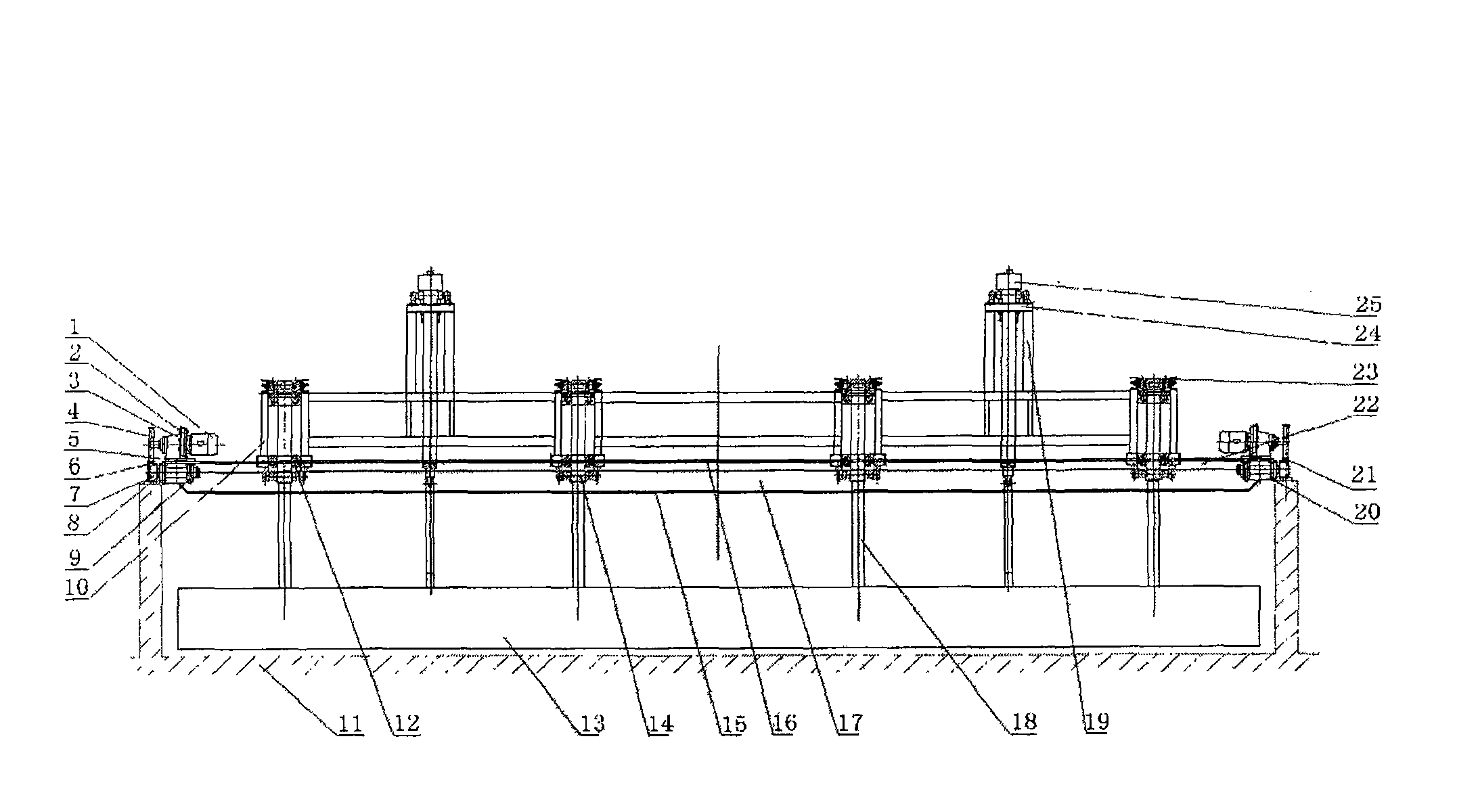

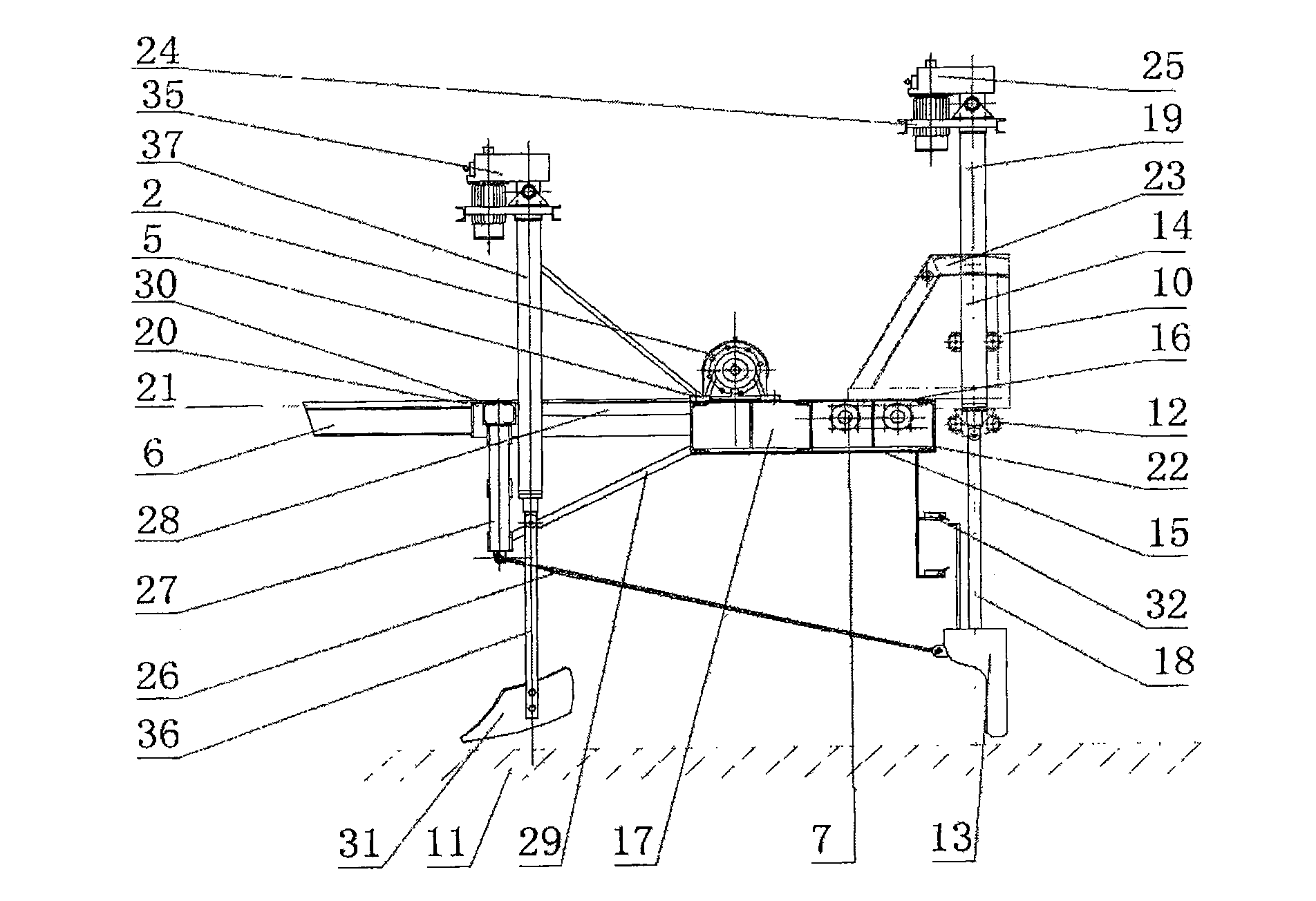

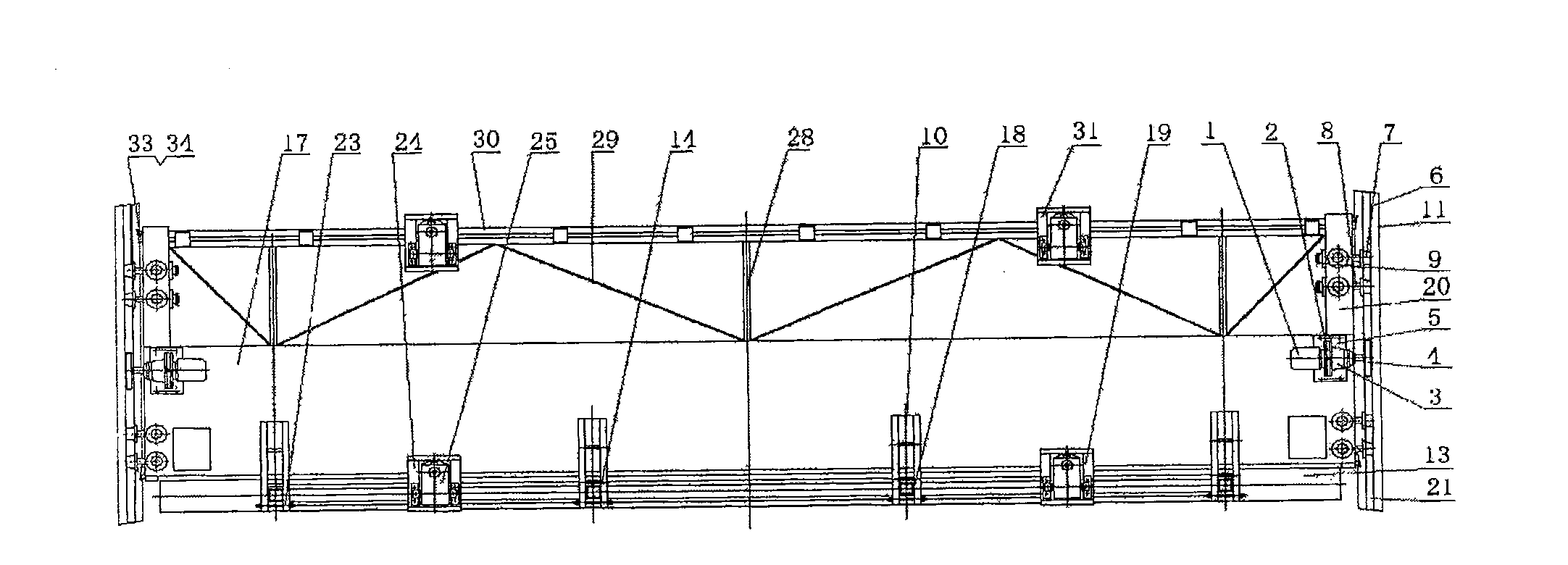

[0014] The motor 1 on the driving type sludge mixing and propulsion machine drives the large gear 4 through the cycloid reducer 3, so that the main beam 17 is connected with the rack 20. The main beam 17 is provided with a wheel shaft 8 and a bearing seat 9 The wheel device 7 is connected with the track 6, the track 6 and the rack 20 are installed on the concrete foundation 11, and the main beam 17 is also provided with a sliding sleeve wheel train 12, a sliding sleeve 14, a bottom plate 15, a panel 16, a slide bar 18, Electric push rod bracket 19, lining beam 21, chute 22, square frame 23, first electric push rod 24, crossbeam 29, rear beam 30, plow blade 31, push mud plate stroke limiter 32, push mud machine stroke limit Device 33, mud pusher anti-deflection limiter 34, second electric push rod 35, lifting bracket 36, lifting guide rail 37, the electric push rod 24 on the square frame 23 and electric push rod support 19 is fixed on the lifting sliding sleeve 14 On, the elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com