Coal gangue brick roasting equipment waste heat recycling device

A technology of waste heat recovery and coal gangue, applied in lighting and heating equipment, preheating fee, charging support, etc., can solve the problems of ineffective use of heat and waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

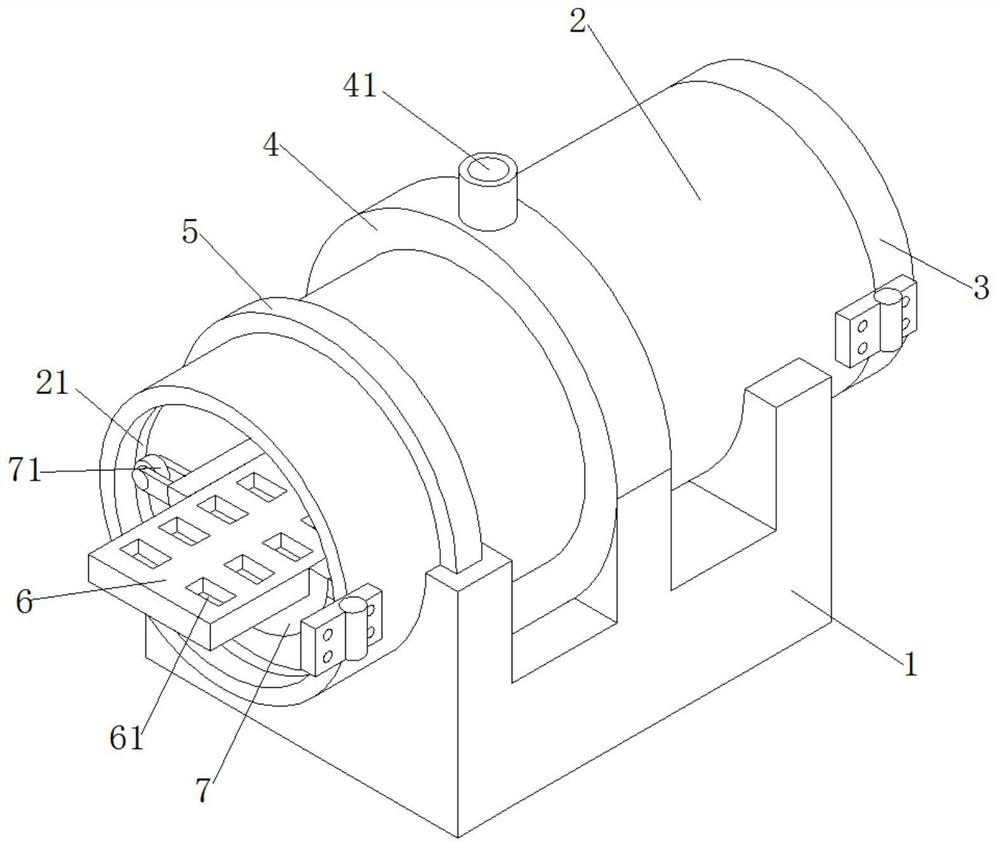

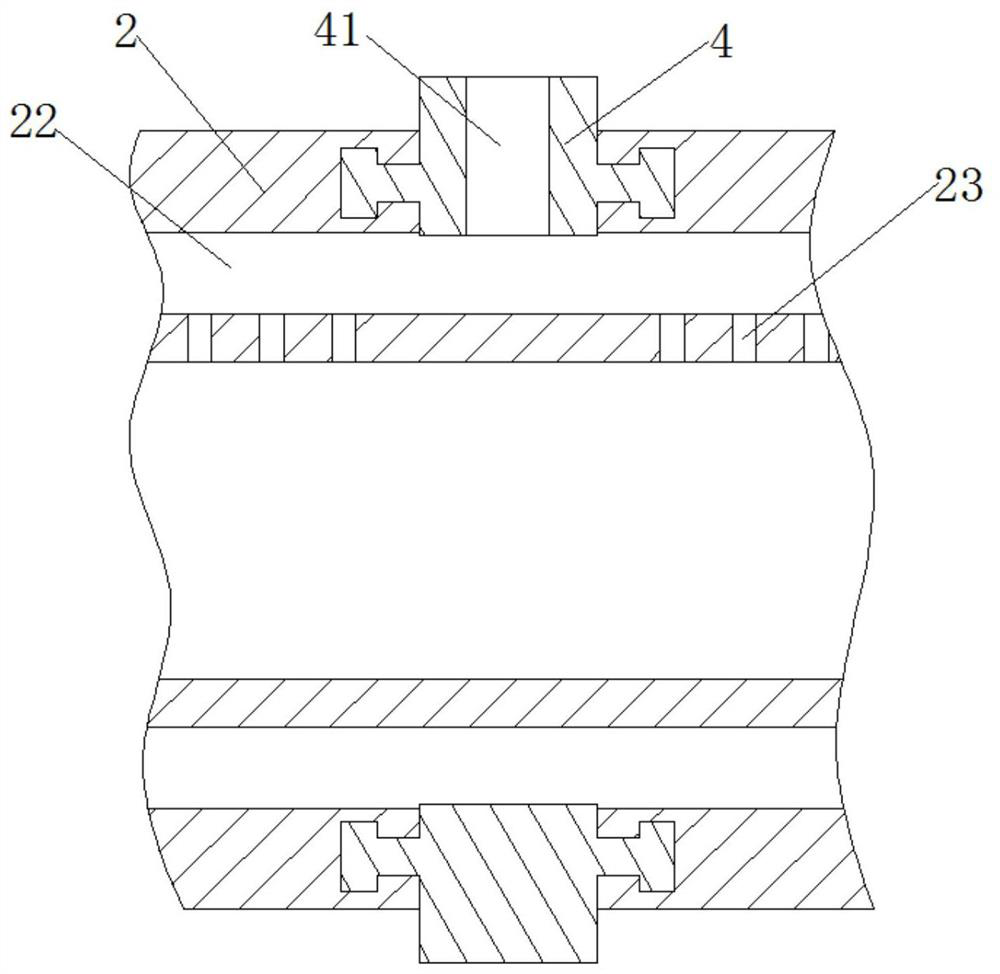

[0023] see Figure 1-4 , this embodiment provides a waste heat recovery device for coal gangue brick roasting equipment, including a bearing bracket 1, the upper end of the bearing bracket 1 is provided with a rotatable drum 2 for transferring heat, and the gangue brick is roasted by the drum 2 The residual heat is transferred to the inner cavity of the drum 2, and the inner cavity of the drum 2 is heated;

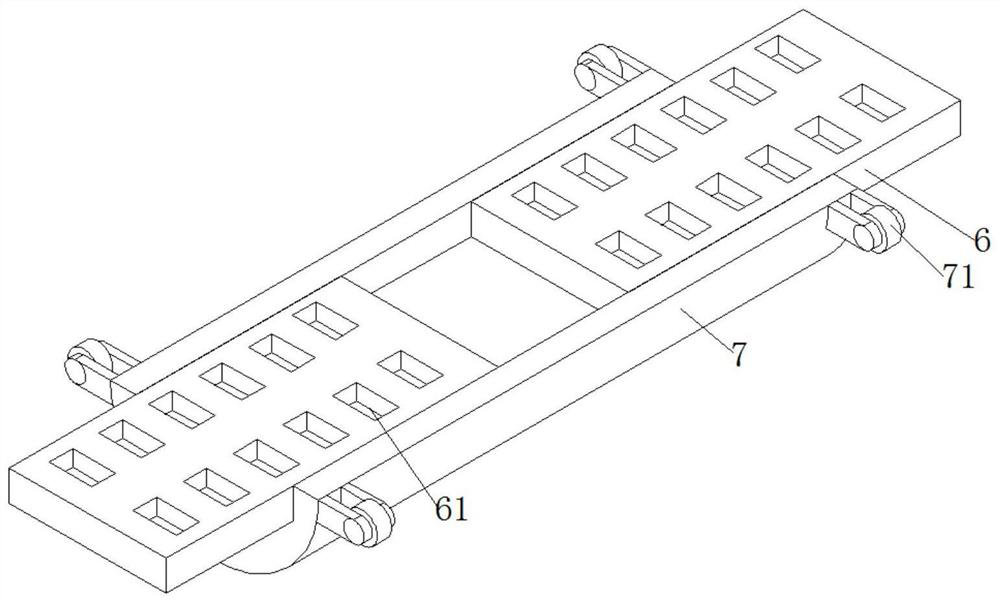

[0024] The inner cavity of the drum 2 is provided with a bearing plate 6 for carrying the brick and keeping the brick facing up in real time, and the bearing plate 6 keeps the brick facing up in real time and can prevent the brick from falling from the bearing plate 6 when the drum 2 moves.

[0025] In order to facilitate the placement of adobes, the upper end surface of the bearing plate 6 is evenly provided with a rectangular groove 61 for placing adobes, and placing the cuboid adobes in the rectangular grooves 61 can prevent the adobes from being deformed during the pre...

Embodiment 2

[0036] see Figure 5 , further improvements have been made on the basis of Example 1:

[0037] In order to prevent the counterweight 7 and the bearing plate 6 from rotating relative to the drum 2 when the brick is placed, the lower end surface of the bearing plate 6 is provided with a fixing mechanism 8 for fixing the counterweight 7 relative to the drum 2 to prevent the counterweight 7 from rotating when the brick is placed. The counterweight 7 and the bearing plate 6 rotate relative to the drum 2 .

[0038] The fixing mechanism 8 includes a chute 82, a movable rod 81 and a limiting groove 86, the chute 82 is located on the lower end surface of the bearing plate 6, the limiting groove 86 is located on the inner cavity wall of the drum 2, and the movable rod 81 Through the counterweight 7, one end of the movable rod 81 slides and fits with the hypotenuse of the chute 82, and the end of the movable rod 81 away from the chute 82 is plugged into the limiting slot 86, and the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com