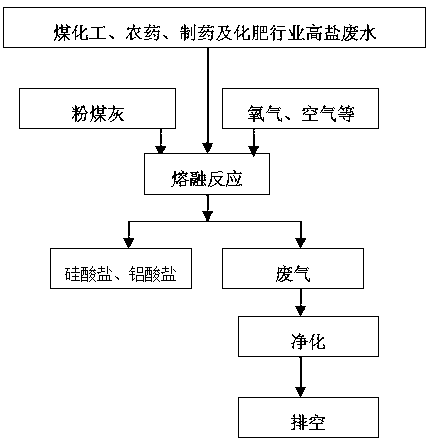

Method for harmlessly treating high-salt wastewater by using fly ash as additive

A technology for harmless treatment of high-salt wastewater, applied in combustion methods, incinerators, lighting and heating equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Put 800 Kg of high-salt wastewater (COD content 9000 mg / L) in the chemical fertilizer industry in an electric furnace, and after heating up to 1350 °C with the electric furnace at 15 °C / min, insert the spray gun into the molten pool to blow oxygen, and the pressure of the oxygen blowing is 1.3 MPa , carry out the oxygen-enriched combustion of organic matter in waste salt, and add 2.2 times of fly ash into the molten pool. X and SO X The flue gas of toxic substances such as flue gas is purified and discharged into the atmosphere. After the melting and combustion treatment, the COD content of the product salt is 30mg / L, and the content of sodium silicate and sodium aluminate exceeds 95%, and the heavy metal elements are basically not leached. At the same time The harmless and resourceful utilization of high-salt wastewater and fly ash has been realized.

Embodiment 2

[0020] Put 700 Kg of high-salt wastewater (COD content 7000 mg / L) in the pesticide industry in an electric furnace, and after heating up to 1400 °C with the electric furnace at 10 °C / min, insert the spray gun into the molten pool to blow oxygen, and the oxygen blowing pressure is 1.5 MPa , carry out the oxygen-enriched combustion of organic matter in the waste salt, and add 1.2 times of fly ash into the molten pool. X and SO X The flue gas of toxic substances such as flue gas is purified and discharged into the atmosphere. After the melting and combustion treatment, the COD content of the product salt is 15mg / L, and the content of sodium silicate and sodium aluminate exceeds 95%, and the heavy metal elements are basically not leached. The harmless and resourceful utilization of high-salt wastewater and fly ash has been realized.

Embodiment 3

[0022] Put 500 Kg of high-salt wastewater (COD content 12,000 mg / L) in the chemical fertilizer industry into an electric furnace, and after heating up to 1050°C with the electric furnace at 10°C / min, insert the spray gun into the molten pool to blow in oxygen, and the oxygen blowing pressure is 3.5 MPa , carry out oxygen-enriched combustion of organic matter in waste salt, and add 3.5 times of fly ash into the molten pool. X and SO X The flue gas of toxic substances such as flue gas is purified and discharged into the atmosphere. After the melting and combustion treatment, the COD content of the product salt is 50mg / L, and the content of potassium silicate and potassium aluminate exceeds 95%, and the heavy metal elements are basically not leached. The harmless and resourceful utilization of high-salt wastewater and fly ash has been realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com