Long-acting evaluation method for active magnesium oxide solidified/stabilized zinc-containing smelting slag based on carbonation accelerated exposure

A technology of active magnesium oxide and zinc smelting slag, which is applied in the direction of instruments, analytical materials, measuring devices, etc., can solve the problems of reducing the compressive strength of heavy metal leaching, reducing the buffer capacity of solidified body, and affecting the release performance of heavy metals, etc., to achieve outstanding gelation The effects of strong bonding strength, strong physical adsorption capacity, and wide-ranging practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

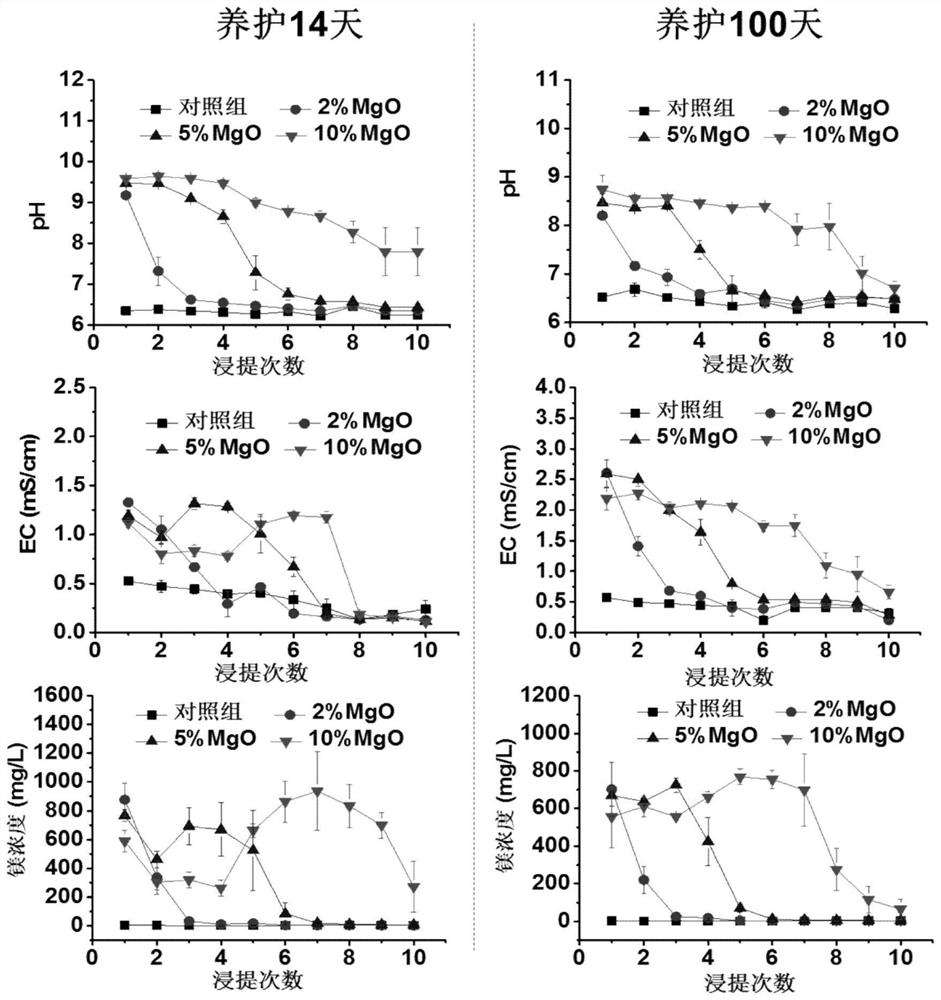

Embodiment 1

[0035] In terms of parts by mass, 100 parts of lead-zinc slag, 2 parts of activated magnesium oxide, and 66 parts of water were uniformly stirred and mixed to prepare a cementitious material slurry. The material is placed in a curing box (temperature 20° C., relative humidity ≥ 95%) for curing for 14 days and 100 days to obtain a cemented and cured zinc-containing slag-based gelling material.

Embodiment 2

[0037] In parts by mass, 100 parts of lead-zinc slag, 5 parts of activated magnesium oxide and 66 parts of water were uniformly stirred and mixed to prepare a cementitious material slurry. The material is placed in a curing box (temperature 20° C., relative humidity ≥ 95%) for curing for 14 days and 100 days to obtain a cemented and cured zinc-containing slag-based gelling material.

Embodiment 3

[0039] In terms of parts by mass, 100 parts of lead-zinc slag, 10 parts of activated magnesium oxide and 66 parts of water were uniformly stirred and mixed to prepare a cementitious material slurry. The material was placed in a curing box (temperature 20° C., relative humidity ≥ 95%) for curing for 14 days and 100 days to obtain a cemented and cured zinc-containing slag-based gelling material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com