Flame-retardant protective coating for rubber and plastic products and preparation method thereof

A technology for protective coatings and rubber and plastic products, used in coatings, fire retardant coatings, epoxy resin coatings, etc. The effect of focusing, reducing migration and leaching, and improving flame retardant performance and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

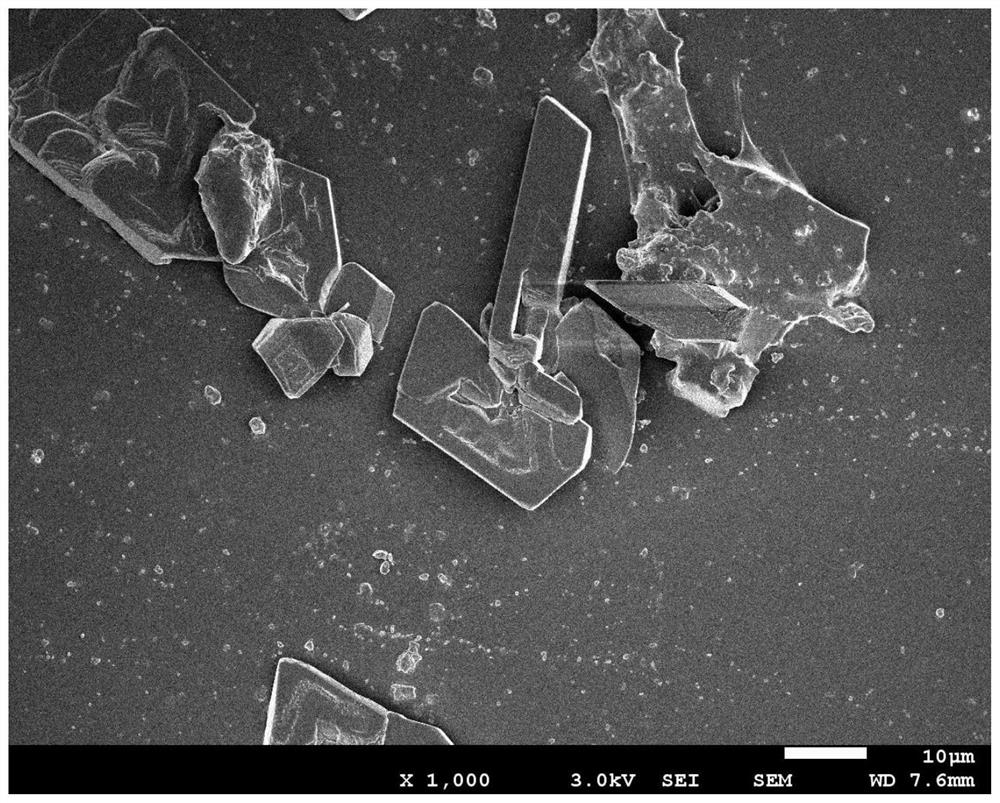

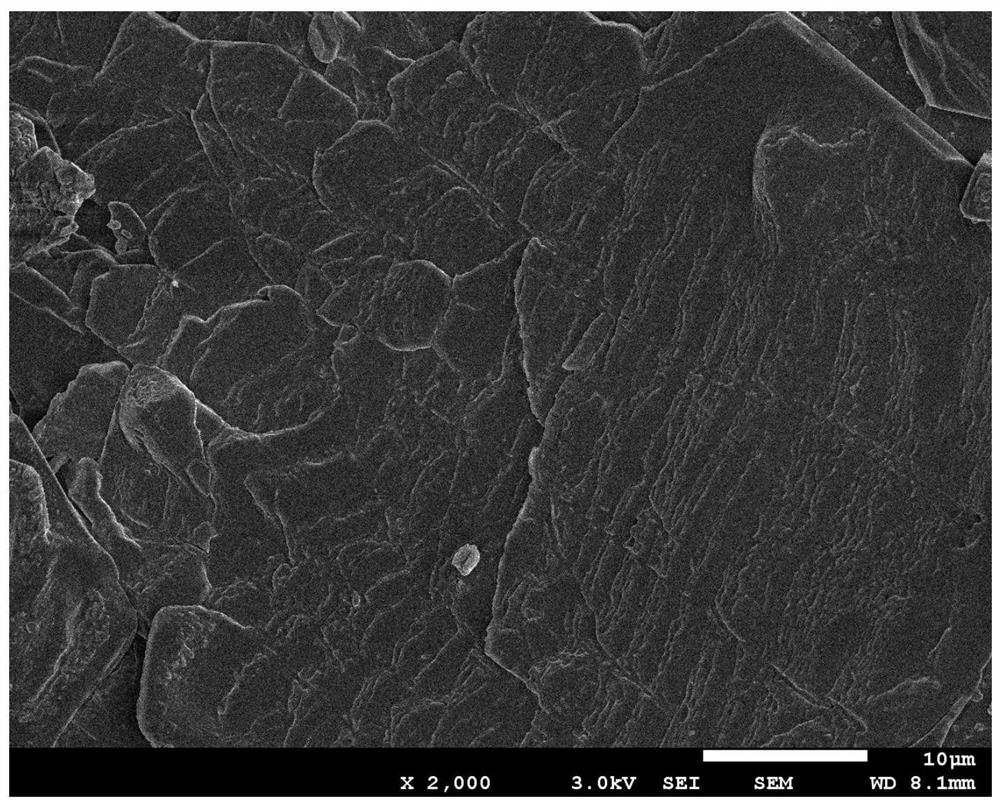

Image

Examples

Embodiment 1

[0039] A flame-retardant protective coating for rubber and plastic products, which is prepared from the following components: 100 parts by mass of novolac epoxy resin, 3 parts by mass of graphene oxide (1-3 layers), 30 parts by mass of ammonium polyphosphate, 1 part by mass of amine, 5 parts by mass of tannic acid, and 1 part by mass of cobalt chloride. The flame retardant protective coating is prepared by the following steps:

[0040] 1) Add graphene oxide, ammonium polyphosphate, ethylenediamine, tannic acid and cobalt chloride to 50 parts by mass of water, react at 300r / min, 60°C for 3h, and obtain dispersion A;

[0041] 2) Add novolac epoxy resin to 200 parts by mass of ethanol, stir at 6000r / min for 10min to dissolve it, and obtain dispersion B;

[0042] 3) Mix the dispersions A and B, and stir at 600r / min for 10min to obtain a flame-retardant protective coating.

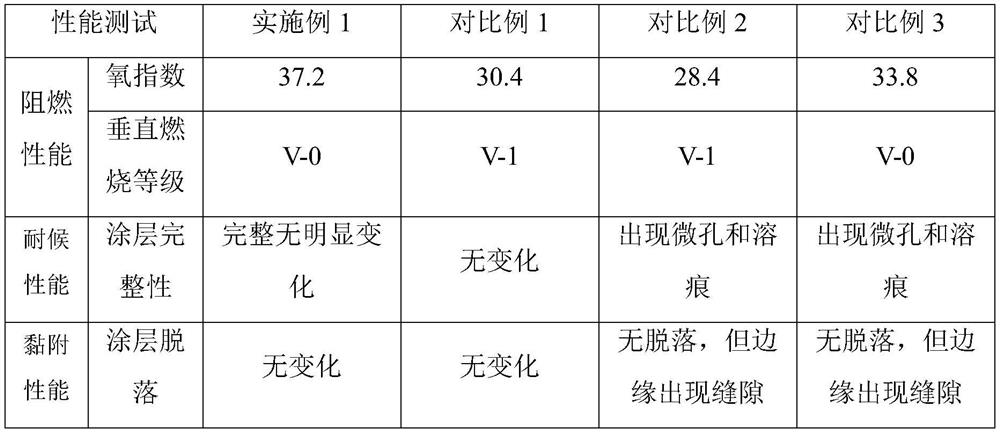

[0043] The flame retardant protective coating was coated on the expanded polystyrene foam board, and its fla...

Embodiment 2

[0048] A flame-retardant protective coating for rubber and plastic products, which is prepared from the following components: 100 parts by mass of polyvinyl chloride, 0.5 parts by mass of organic clay (1-10 layers), 50 parts by mass of red phosphorus, and 10 parts by mass of polyethyleneimine Parts by mass, 50 parts by mass of WK extract, 10 parts by mass of ferric chloride. The flame retardant protective coating is prepared by the following steps:

[0049] 1) Add organoclay, red phosphorus, polyethyleneimine, WK tannin extract and ferric chloride into 100 parts by mass of water, react at 600r / min, 80°C for 1h, and obtain dispersion A;

[0050] 2) Add polyvinyl chloride to 500 parts by mass of acetone, stir at 3000r / min for 30min to dissolve it, and obtain dispersion B;

[0051] 3) Mix the dispersions A and B, and stir at 1000r / min for 30min to obtain a flame retardant protective coating.

[0052] The flame retardant protective coating was coated on the expanded polystyrene ...

Embodiment 3

[0056] A flame-retardant protective coating for rubber and plastic products, which is prepared from the following components: 100 parts by mass of water-based polyurethane, 20 parts by mass of black phosphorus nanosheets (1-20 layers), 5 parts by mass of decabromodiphenyl ether, and 0.5 parts by mass of diamine, 4 parts by mass of oak extract, 0.3 parts by mass of copper chloride. The flame retardant protective coating is prepared by the following steps:

[0057] 1) Add black phosphorus nanosheets, decabromodiphenyl ether, hexamethylenediamine, oak extract and copper chloride to 50 parts by mass of water, react at 600r / min, 80°C for 1h, and obtain dispersion A ;

[0058] 2) Add water-based polyurethane to 100 parts by mass of water, stir at 1000r / min for 15min to dissolve it, and obtain dispersion B;

[0059] 3) Mix the dispersions A and B, and stir at 4500r / min for 10min to obtain a flame retardant protective coating.

[0060] The flame retardant protective coating was coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com