Cermet high level waste forms

a high-level waste and mercury technology, applied in the field of mercury, can solve the problems of high-level radioactive decay, above-ground method suffers from a number of drawbacks, undesirably large quantities of glass for a given quantity of fission product, etc., and achieve the effect of stabilizing high-level waste and reducing waste volum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

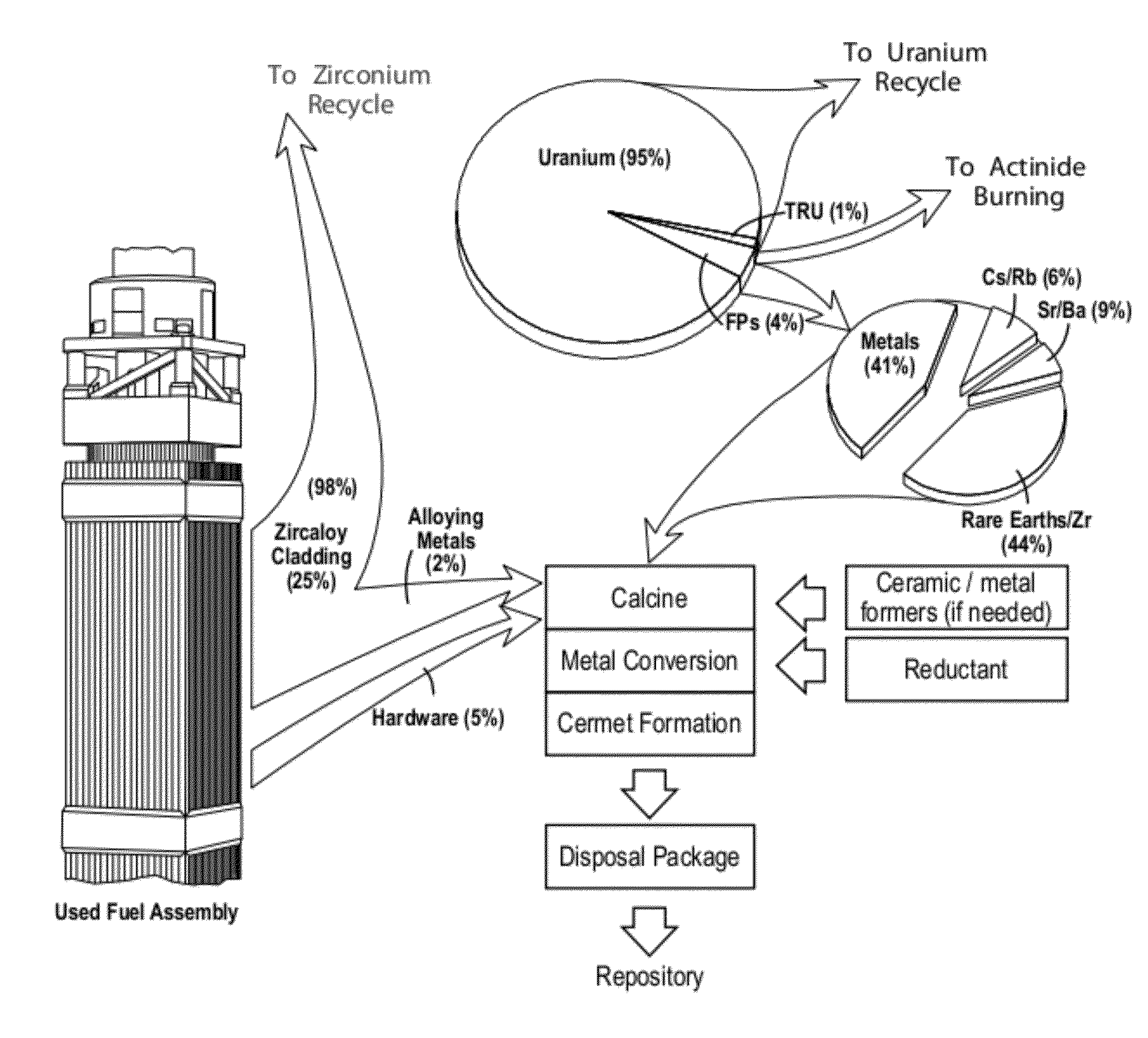

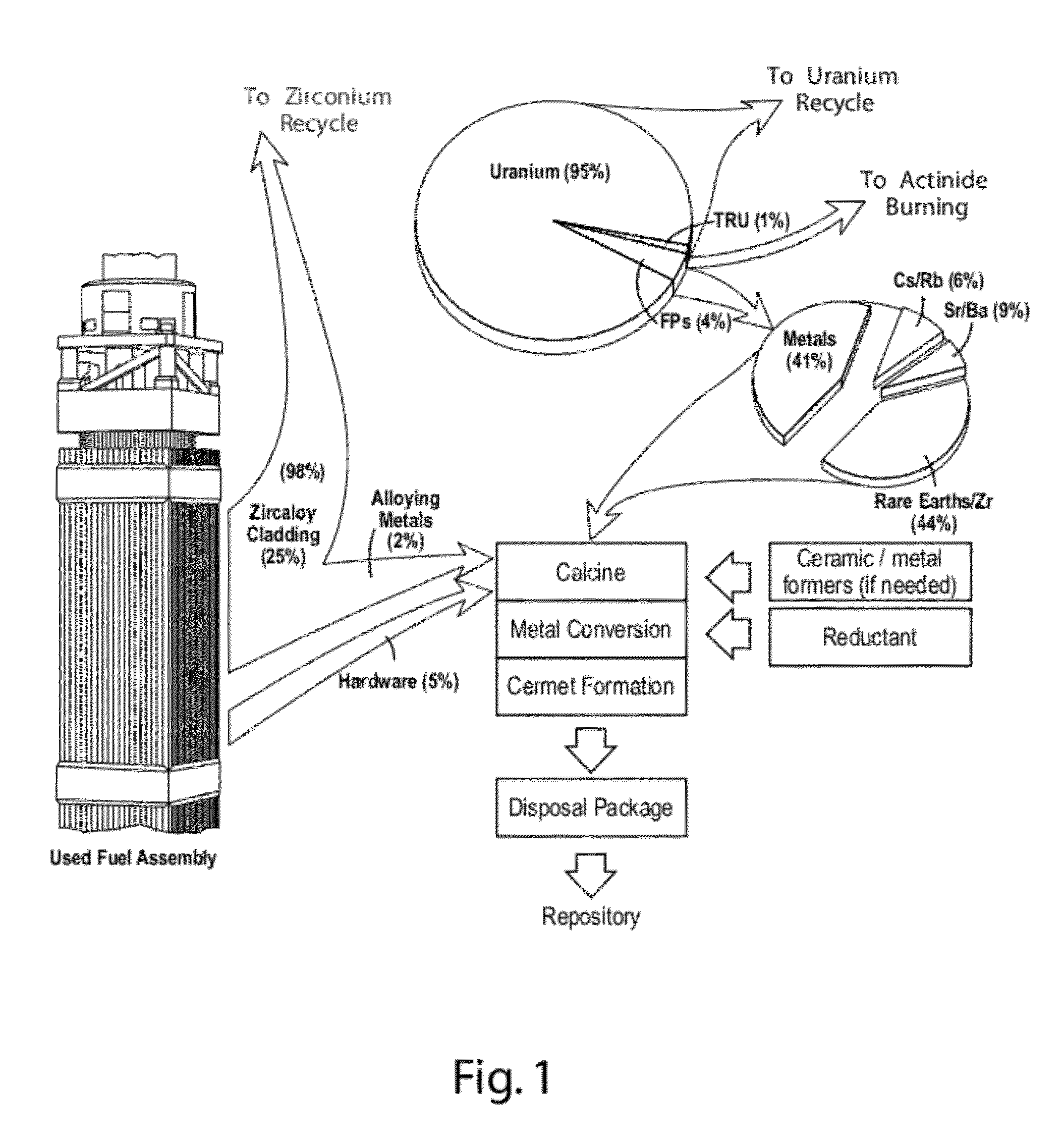

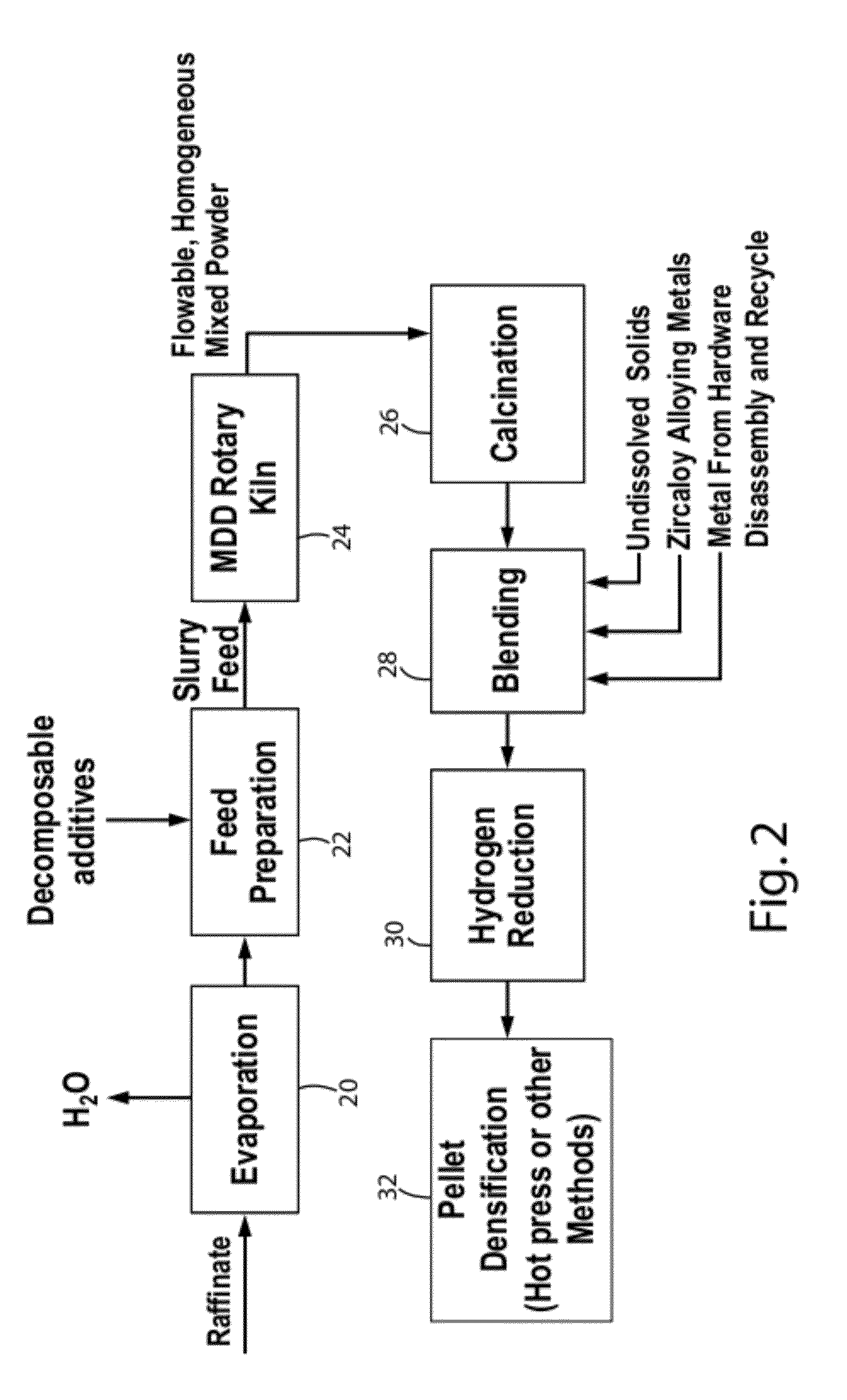

[0017]The invention as contemplated and disclosed herein includes a system and method for stabilizing fission products in a cermet for long term storage. The system and method generally include blending a calcined oxide powder with undissolved fission product metals, zircaloy alloying metals, and / or other metals prior to hydrogen reduction and hot pressing or sintering.

[0018]In one embodiment, an improved cermet includes a composite of ceramic phases encapsulated in a metal matrix. The ceramic phases immobilize at least a first radioisotope in a stable, low-leachability chemical form (e.g., non-water soluble), and the metal matrix immobilizes at least a second radioisotope. As described in greater detail below, the cermet can be formed by blending a homogeneous oxide powder with undissolved high level waste. The homogeneous oxide powder can be formed by first reacting an aqueous solution with molten urea, precipitating or evaporating the resulting constituents, and denitrating the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com