Fly ash detoxification treatment method and equipment

A treatment method and fly ash technology, applied in the field of fly ash treatment, can solve the problems of insufficient research and application of fly ash detoxification and resource utilization, reduction treatment of fly ash and biogas residue, complicated process, etc. Sustained development, realization of solidification and detoxification, and improvement of residue content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

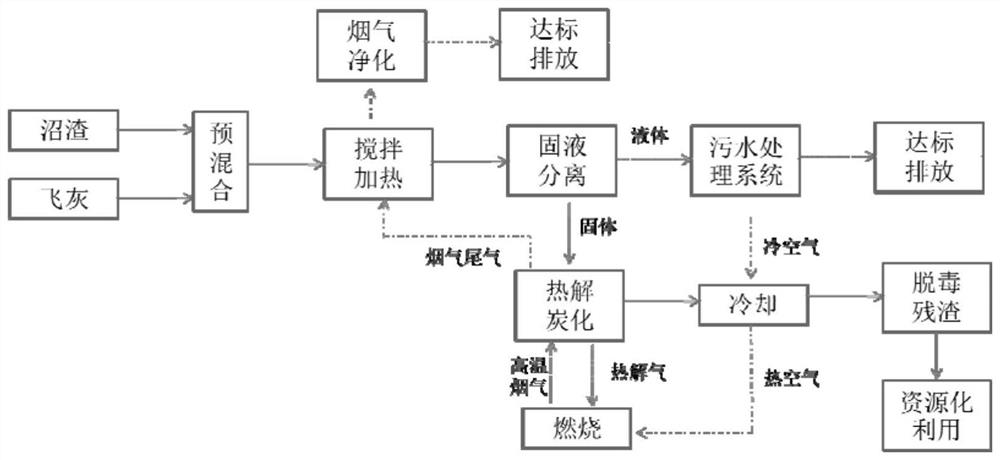

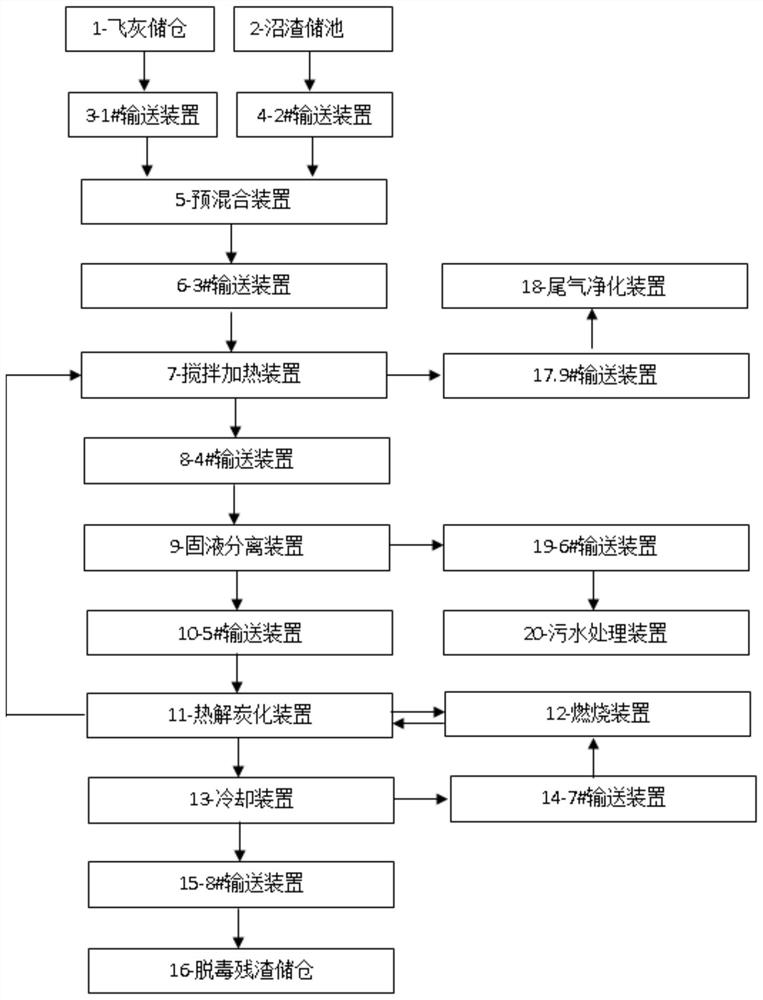

Method used

Image

Examples

Embodiment 1

[0061] Mix a certain quality of biogas residue (moisture content 80%) and fly ash accounting for 20% of the mass of wet biogas residue, and stir vigorously at a speed of 100r / min for 0.5h to obtain a premixed mortar; Heat and stir at ℃ for 60 min to obtain heated mortar. The heated mortar is subjected to solid-liquid separation by pressure filtration to obtain liquid and solid. Put the liquid into the sewage treatment system of the sewage treatment plant and discharge it after reaching the standard. The solid was subjected to pyrolysis and carbonization treatment at 600° C. for 40 minutes to obtain a detoxified residue. The generated pyrolysis gas is burned to generate heat to provide heat for the pyrolysis process, and the high-temperature flue gas generated by the pyrolysis gas combustion is used as a heat source to heat the premixed mortar. The leaching of heavy metals from the detoxification residue is determined by the HJ / T299-2007 method, which is lower than the GB5085...

Embodiment 2

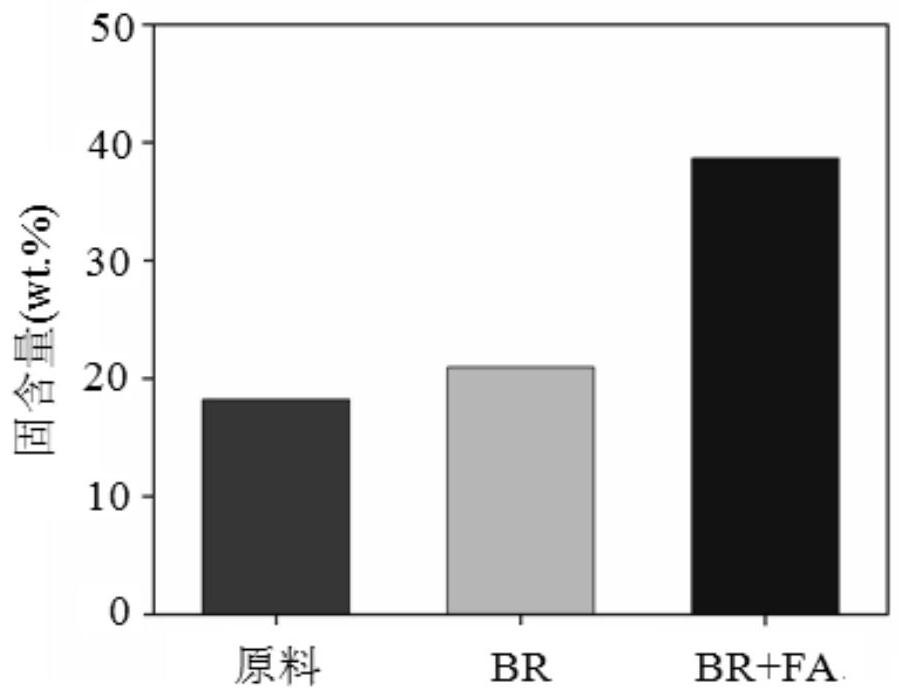

[0063] The wet base biogas residue and fly ash are mixed, wherein the proportion of fly ash added is 20% of the mass of the wet biogas residue. Stir vigorously at a speed of 100r / min for 0.5h to obtain a premixed mortar, and stir and heat the premixed mortar at 180°C for 60min under airtight conditions to obtain a heated mortar, which is called BR+FA. Put the heated mortar into a floor-standing centrifuge, centrifuge at 25°C at a speed of 3000r / min for 20min, and then remove the supernatant to obtain a centrifugally dehydrated solid phase. Dry the centrifugally dehydrated solid phase at 105°C for 24 hours to obtain the solid content; heat the centrifugally dehydrated solid phase in a constant temperature oven at 75°C continuously, record the change of moisture content every 15 minutes until it stops changing, and obtain the change of moisture content with time The curve is the dehydration solid phase drying characteristic curve. The above solid content rate and drying charact...

Embodiment 3

[0066] 100% biogas residue heated mortar press filter solid phase (BRH), 80% biogas residue mixed with 20% fly ash heated mortar press filter solid phase (BR+FAH) were dried and used for pyrolysis experiments. Take 30 g of experimental samples and put them into a tube pyrolysis furnace for pyrolysis. During the pyrolysis process, 20 mL / min of nitrogen gas was introduced as a protective gas, and the temperature was heated from room temperature to 600 °C at a heating rate of 15 °C / min. After 45 minutes of constant temperature, the pyrolysis ended, and after cooling to room temperature with the pyrolysis furnace, a pyrolysis residue was obtained. They are recorded as BRHC and BR+FAHC respectively. The dry samples of BRH, BRHC, BR+FAH, and BR+FAHC were analyzed for TCLP leaching characteristics of heavy metals, and compared with the dry samples of biogas residue (BR) and fly ash (FA), the results are shown in the table.

[0067] Table 1 Sample heavy metal TCLP analysis / (mg / L)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com