Graphene oxide for electrochemical reduction and preparation method of graphene

A graphene and electrochemical technology, applied in the field of nanomaterials, can solve the problems of high equipment and environmental requirements, limited performance and application, thick graphene sheet thickness, etc., and achieves the effects of low cost of raw materials, easy operation and simple device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

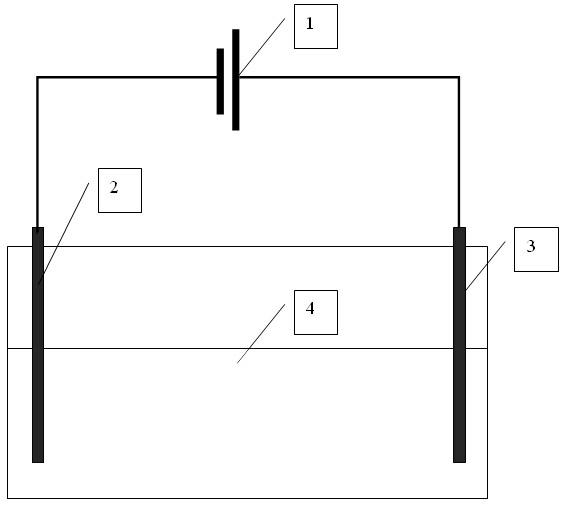

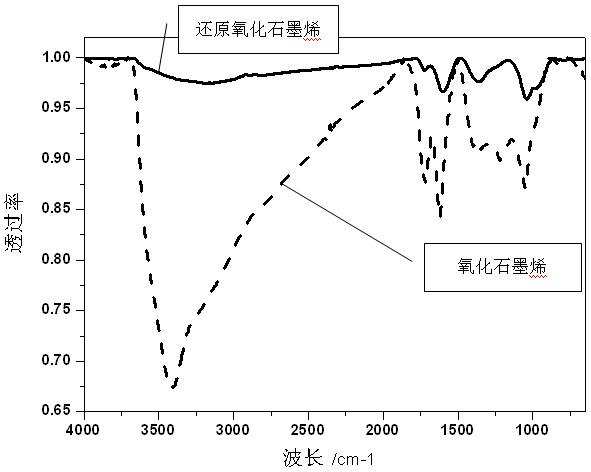

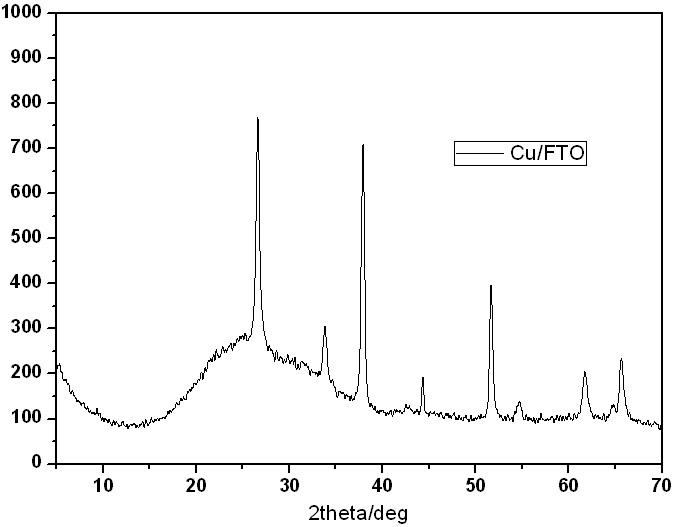

[0030] Embodiment 1: Cu sheet is used as anode, FTO is used as cathode, and the concentration of graphene oxide solution is 1mg / ml

[0031] Using 30μm graphite oxide as raw material, dissolve graphite oxide in deionized water, and obtain a 1mg / ml graphene oxide solution by ultrasonic stripping; fully clean copper sheet and FTO conductive glass electrode material with tap water, and then put them into ethanol solution respectively During the process, ultrasonic for 10 minutes, and finally cleaned with deionized water; fully wash the self-made cuboid glass container with tap water, then add ethanol solution to it, ultrasonic for 10 minutes, and finally rinse with deionized water; measure 60ml of prepared graphene oxide Add the sol into a self-made cuboid glass container; connect the copper sheet and the FTO conductive glass with one end of the copper wire with a clip, and then put the electrode into the above-mentioned graphene oxide sol to fix it, and the other end of the copper...

Embodiment 2

[0033] Embodiment 2: Cu sheet is used as anode, FTO is used as cathode, and the concentration of graphene oxide solution is 2mg / ml

[0034] Use 30μm graphite oxide as raw material, dissolve it in deionized water, and obtain a 2mg / ml graphene oxide solution by ultrasonic stripping; fully clean the copper sheet and FTO conductive glass electrode material with tap water, and then put them into ethanol solution respectively, and ultrasonically 10min, and finally rinsed with deionized water; fully cleaned the self-made cuboid glass container with tap water, then added ethanol solution to it, ultrasonicated for 10min, and finally rinsed with deionized water; measured 60ml of prepared graphene oxide sol, added into a self-made rectangular parallelepiped glass container; use one end of the copper wire with a clip to connect the copper sheet and the FTO conductive glass, and then put the electrode into the above-mentioned graphene oxide sol to fix it, and the other end of the copper wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com