Laser-driven gas defense device

A laser-driven, transmission technology, applied to machines/engines, container discharge methods, and equipment discharged from pressure vessels, etc., can solve problems such as safety hazards, avoid personal hazards, have strong controllability, and prevent chlorine gas. The effect of further diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

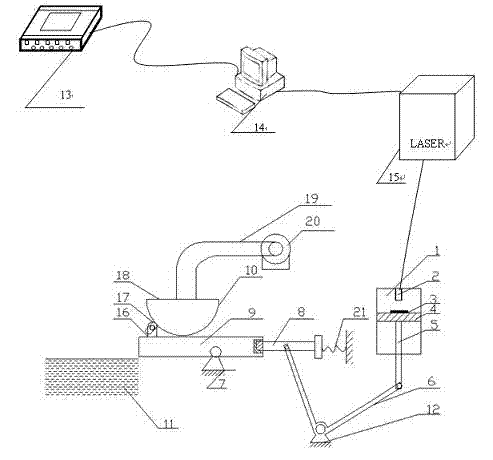

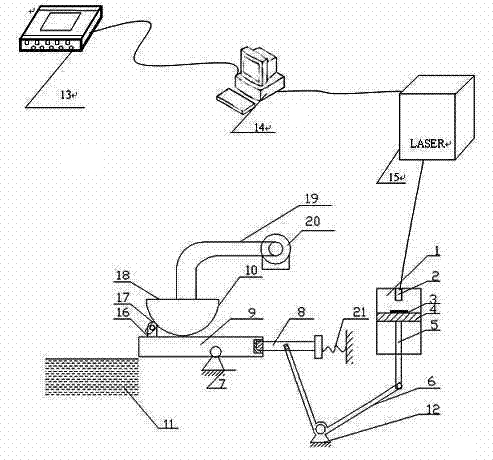

[0019] In order to understand the technical solution, the device will be further described in conjunction with the accompanying drawings:

[0020] The invention is based on a laser-driven anti-virus device, including a gas detection controller, a computer, a laser generator, a laser-driven anti-virus transmission mechanism, a storage liquid chlorine bottle and a dissolution pool filled with alkaline solution.

[0021] Such as figure 1 The transmission device based on laser drive shown includes piston cylinder 1, piston 4, piston rod 5, connecting rod 6, frame 12, support 7, positioning pin 8, bracket 9, storage bottle 10, pin seat 16, Lifting lug 17, bottle cap 18, wall plate 19, motor 20, spring 21, when the liquid chlorine leaks, the laser generator emits laser light, pushes the piston 4 to do work, and the piston rod 5 drives the connecting rod 6, thereby sending the storage bottle 10 into the A neutralization reaction occurs in the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com