Dust removal system for rubber mixing mill

A technology of dust removal system and rubber mixing machine, which is applied in the direction of dust removal, cleaning methods and utensils, and dispersed particle filtration. Personal hazard, good filtering effect, easy to vacuum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

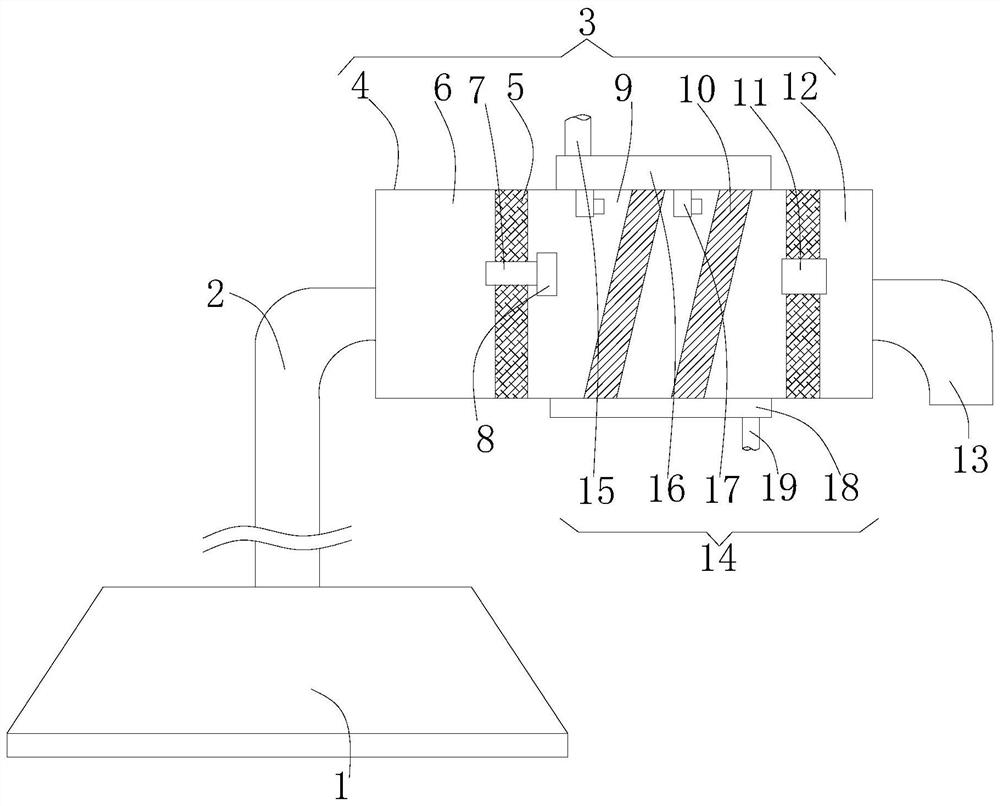

[0030] refer to Figure 1-6 Shown is the preferred embodiment provided by the present invention.

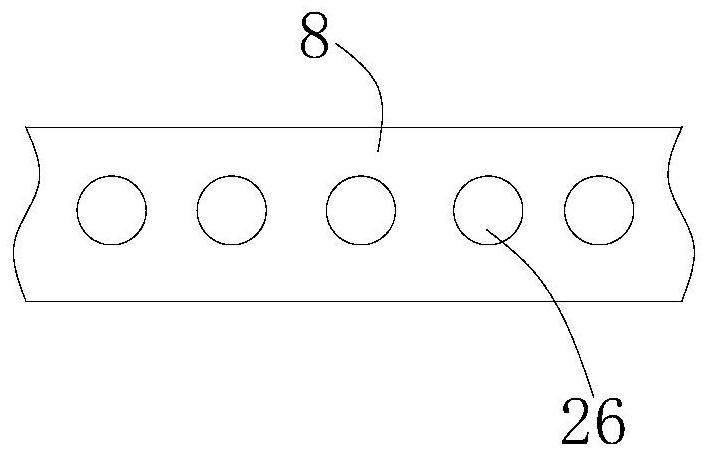

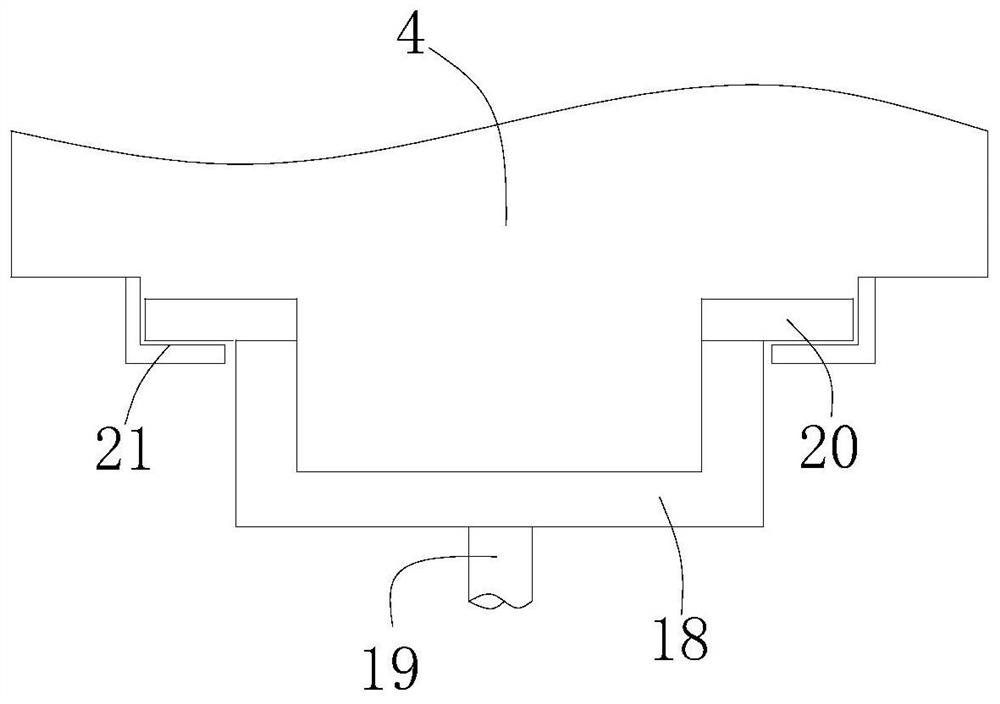

[0031] A dust removal system for a rubber mixing machine, comprising a dust cover 1, the top of the dust cover 1 is connected to a connecting pipe 2, and the end of the connecting pipe 2 is connected to a dust-proof mechanism 3, and the dust-proof mechanism 3 includes a box body 4, the box body Both sides of the box 4 are provided with partitions 5. The partitions 5 divide the interior of the box body 4 into a dust collection chamber 6, a dust removal chamber 9 and a purification chamber 12. On the partition 5 between the dust collection chamber 6 and the dust removal chamber 9 A first through pipe 7 is provided, and a plurality of filter plates 10 are arranged inside the dust removal chamber 9, and a circulation dust removal mechanism 14 is also arranged inside the dust removal chamber 9, and the circulation dust removal mechanism 14 and the interior of the dust removal chamber ...

Embodiment 2

[0038] The technical solution is: a dust suction tube 22 is arranged in the dustproof cover 1, an air outlet tube 24 is arranged on the upper side of the middle part of the dust suction tube 22, the end of the air outlet tube 24 is connected to the connecting pipe 2, and a threaded connection is provided at the bottom of the dust suction tube 22. Cylinder 25, the threaded connection cylinder 25 is directly connected with the rubber mixing machine through a connecting hose, the external device provides power, and the dust directly enters the interior of the dust suction cylinder 22 through the threaded connection cylinder 25.

[0039] The rest of the technical solutions are the same as those in Embodiment 1, and such setting makes the dust inside the rubber mixing machine directly discharged into the inside of the dustproof cover 1, thereby completely avoiding the possibility of flying dust.

[0040] In this embodiment, the entire operation process can be controlled by a compute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com