Automatic sorting method for construction waste

A technology for automatic sorting and construction waste, which is applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc. , The effect of reducing labor cost and high sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

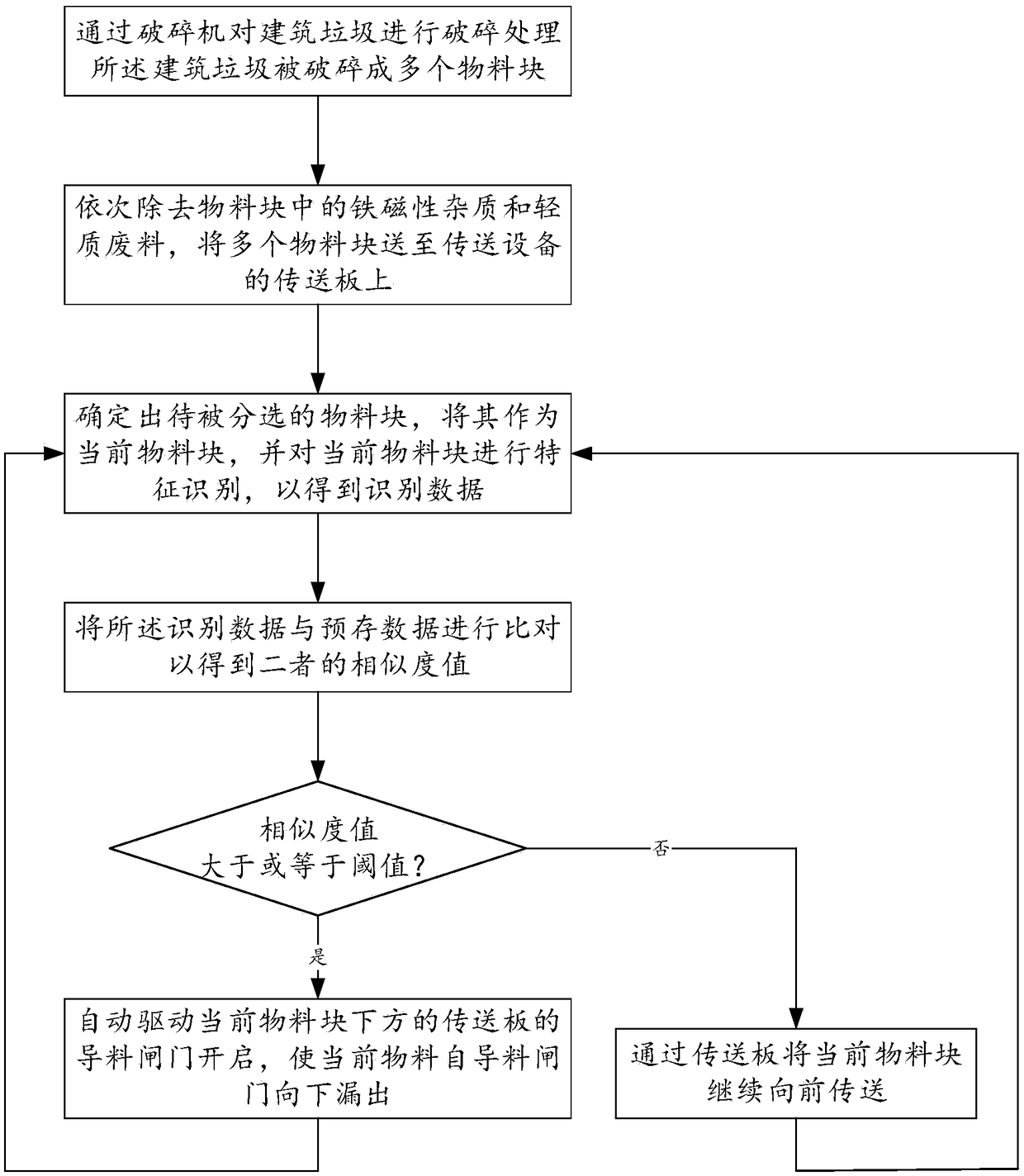

[0044] Such as figure 1 , 3 As shown, the automatic sorting method of this embodiment includes the following steps.

[0045] In step 1, the construction waste is crushed by a crusher, and the construction waste is broken into multiple material blocks, and the size of each material block is smaller than or equal to a preset size, for example, the preset size is 120mm in diameter.

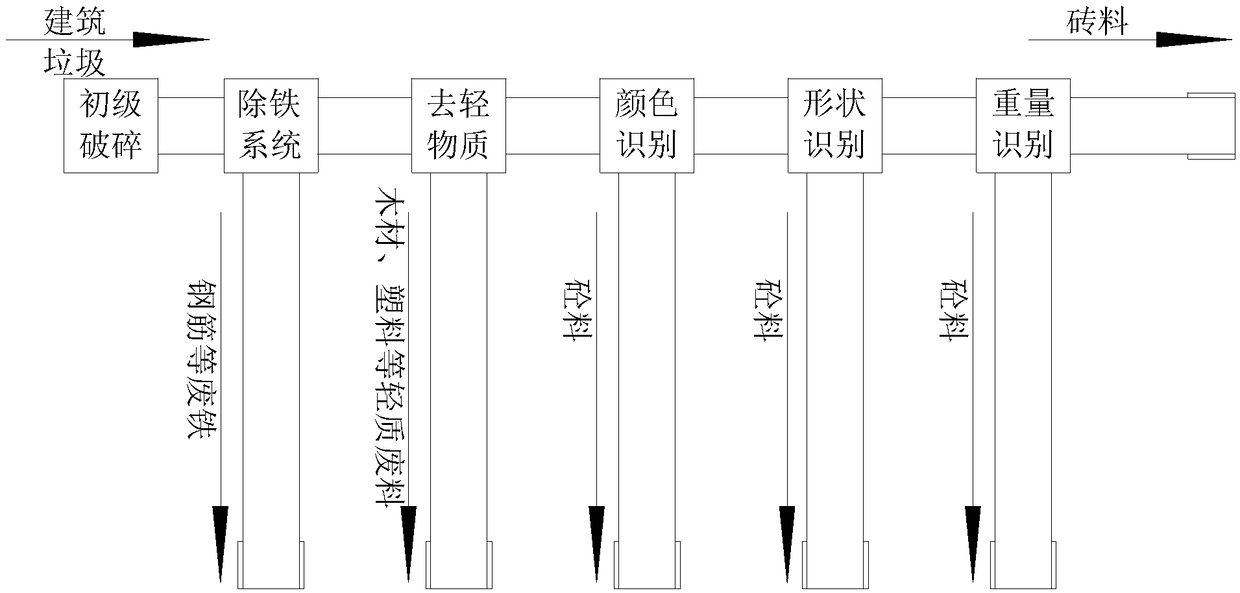

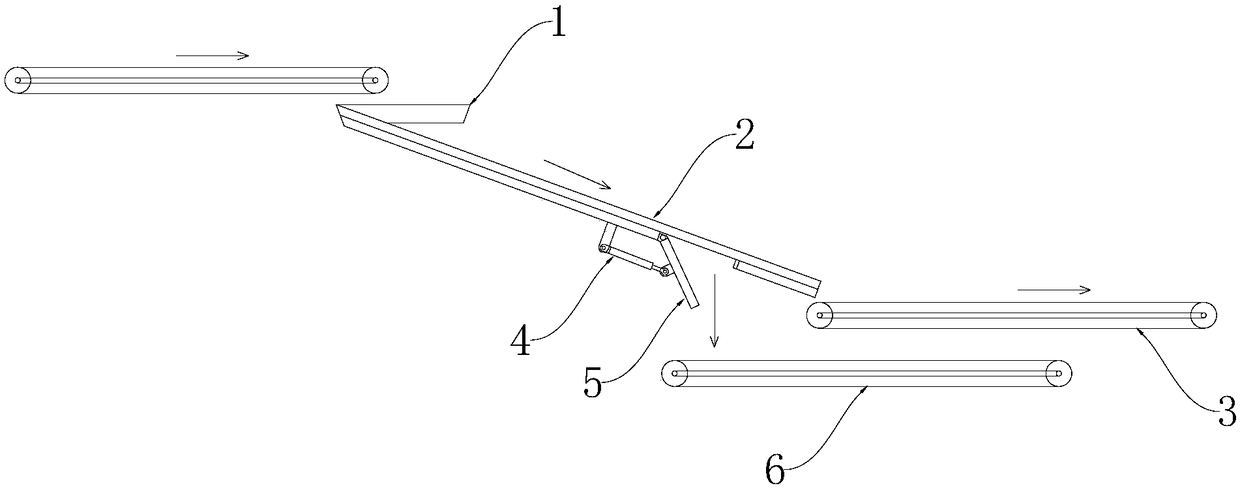

[0046] Step 2, remove the ferromagnetic impurities and light waste in the material blocks in turn, the remaining material blocks are mainly concrete material blocks and brick material blocks, and send multiple material blocks to the transmission plate of the transmission device 2; this embodiment In this method, the front end of the conveying device 2 is provided with a feeding trough 1; in this step 2, a plurality of material blocks are placed in the feeding trough 1, and the material blocks flow from the outlet of the feeding trough 1 to the conveying plate of the conveying device 2 superior. In...

Embodiment 2

[0053] The scheme of this embodiment is basically the same as that of Embodiment 1, the difference is that in this embodiment, step 3 also includes the step of identifying the weight feature of the current material block through the pressure sensor installed at the bottom of the conveying plate, so as to obtain the weight Identification data; in this embodiment, the pressure sensor is installed at the bottom of the material guide gate.

[0054] In step 4, the pre-stored data includes pre-stored weight data, and the threshold includes a third threshold; if the similarity between the weight identification data and the pre-stored weight data is greater than the third threshold (for example, the similarity between the weight identification data and the pre-stored weight data is greater than 80%) ), then perform step 5; otherwise perform step 6; in this embodiment, in order to ensure that the pressure sensor is always in a high-precision state, when the weight of the current materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com