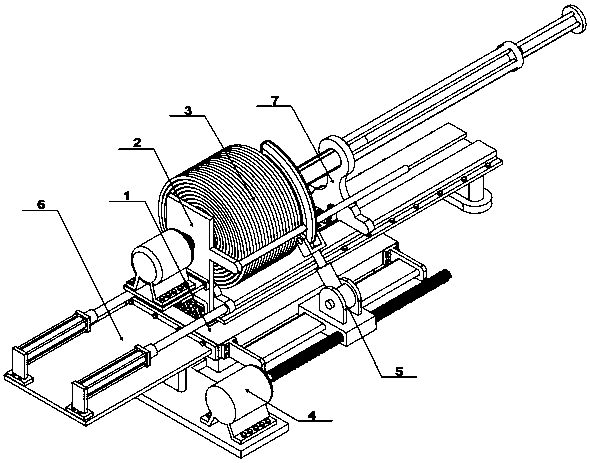

Wire-twisting-preventing coiling device for electrotechnical round aluminum rod

A round aluminum rod, electrician technology, applied in the direction of transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problems of high work intensity, inconvenient removal, personal harm to staff, etc. The effect of improving usability and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

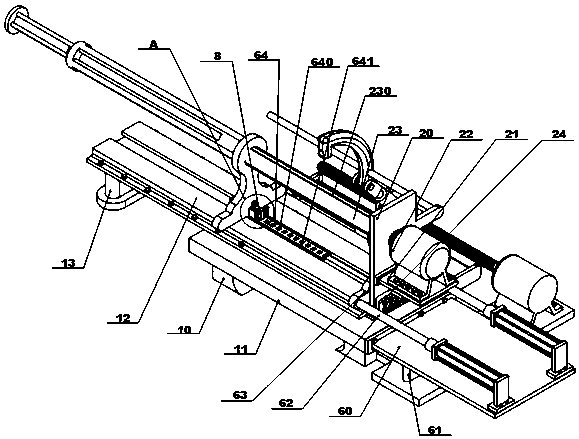

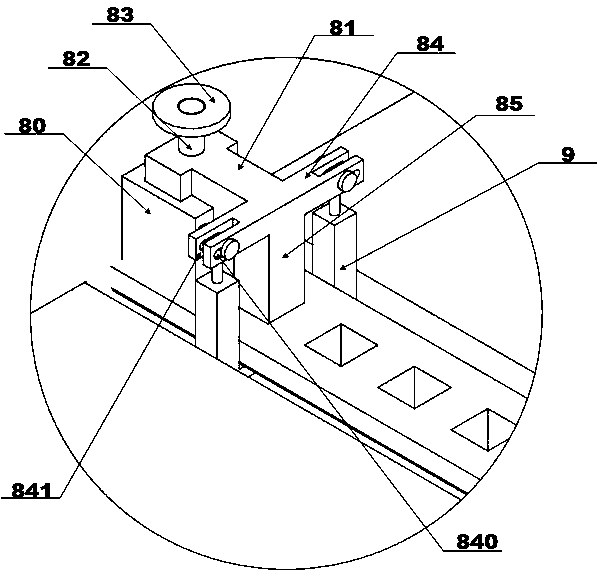

[0070] 1. Adjust the position of the end motion support plate 70 according to the length required for roll making. When the end motion support plate 70 is determined to be at the position, rotate the two rotating rods 82 respectively, so that the lower insert 85 moves into the lower socket 640, and Rotate the lower clip 92 so that each lower clip 621 is placed in the lower clip 641, and the position of the end movement support plate 70 is fixed;

[0071] 2. Pass one end of the electrician's round aluminum rod through the threading hole 521 to the winding rod 23, and bend the end, and place the bent end in the rod groove 230;

[0072] 3. Start the stepper motor 41, so that the roll-making limiter 52 is close to the inner side of the push plate 63;

[0073] 4. Start the wire winding motor 22 to start rolling. If it is a coil for making a circle, the stepping motor 41 starts to run, and at this time the limit cylinder 51 is closed. As the number of turns of the electric circle al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com