Epoxy resin curing agent based on methyl methacrylate bottom waste and its preparation method and application

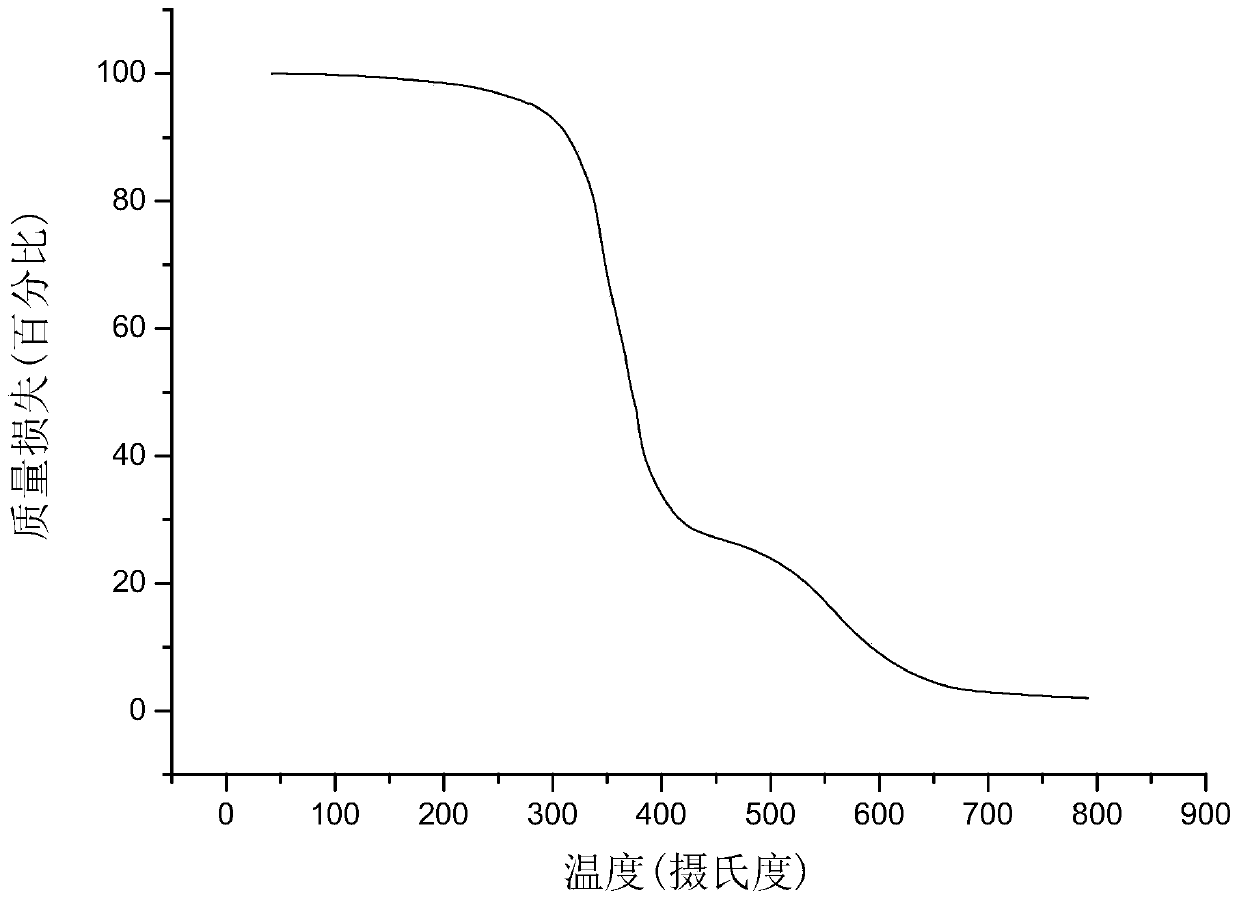

A technology for curing methyl methacrylate and epoxy resin, which is applied in the preparation of carboxylic acid amides, chemical instruments and methods, preparation of organic compounds, etc. problems, to reduce personal injury and environmental pollution, simple production process, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0029] Specific embodiment one: adopt the reflux reactor with water divider to prepare curing agent in the present embodiment, concrete preparation method is to carry out according to the following steps:

[0030] Step 1: Add 81.057g of waste produced in the production of methyl methacrylate to the reactor, then add 74.132g of triethylenetetramine, add 4.6g of cyclohexane into the water separator as a water-carrying agent, and add 1g of Cyclohexane, heated to reflux reaction at 70°C, methanol or water in the system is taken out during the reaction, when the interface between methanol and cyclohexane no longer rises (when the interface between water and cyclohexane no longer rises), the system There is no methane, the reaction ends;

[0031] Step 2, then add 18.684g of dodecyl to tetradecyl glycidyl ether (AGE), and heat the reaction at 70°C for 30 minutes, the obtained curing agent, the product is transferred from the outlet at the bottom of the kettle to the storage tank Sav...

PUM

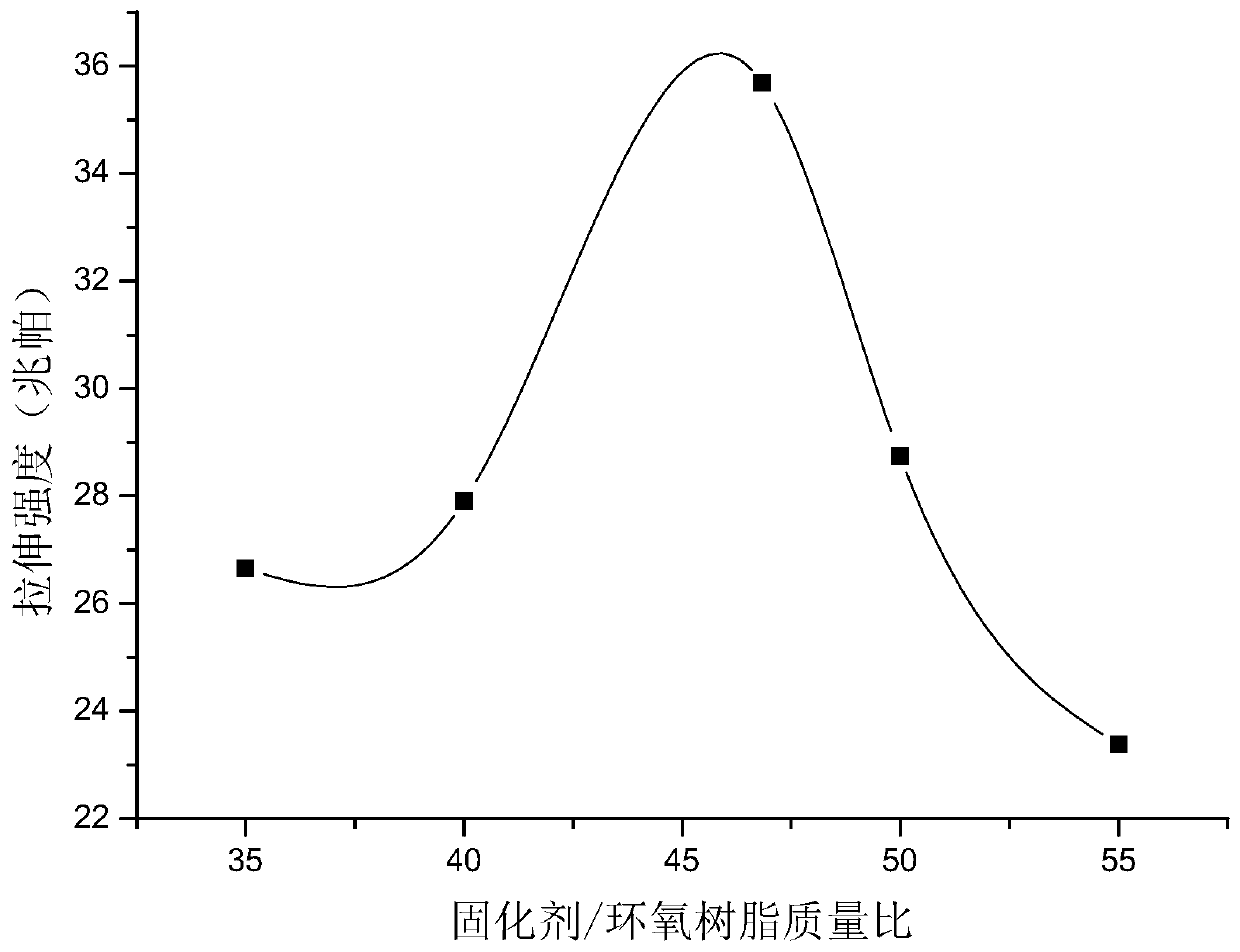

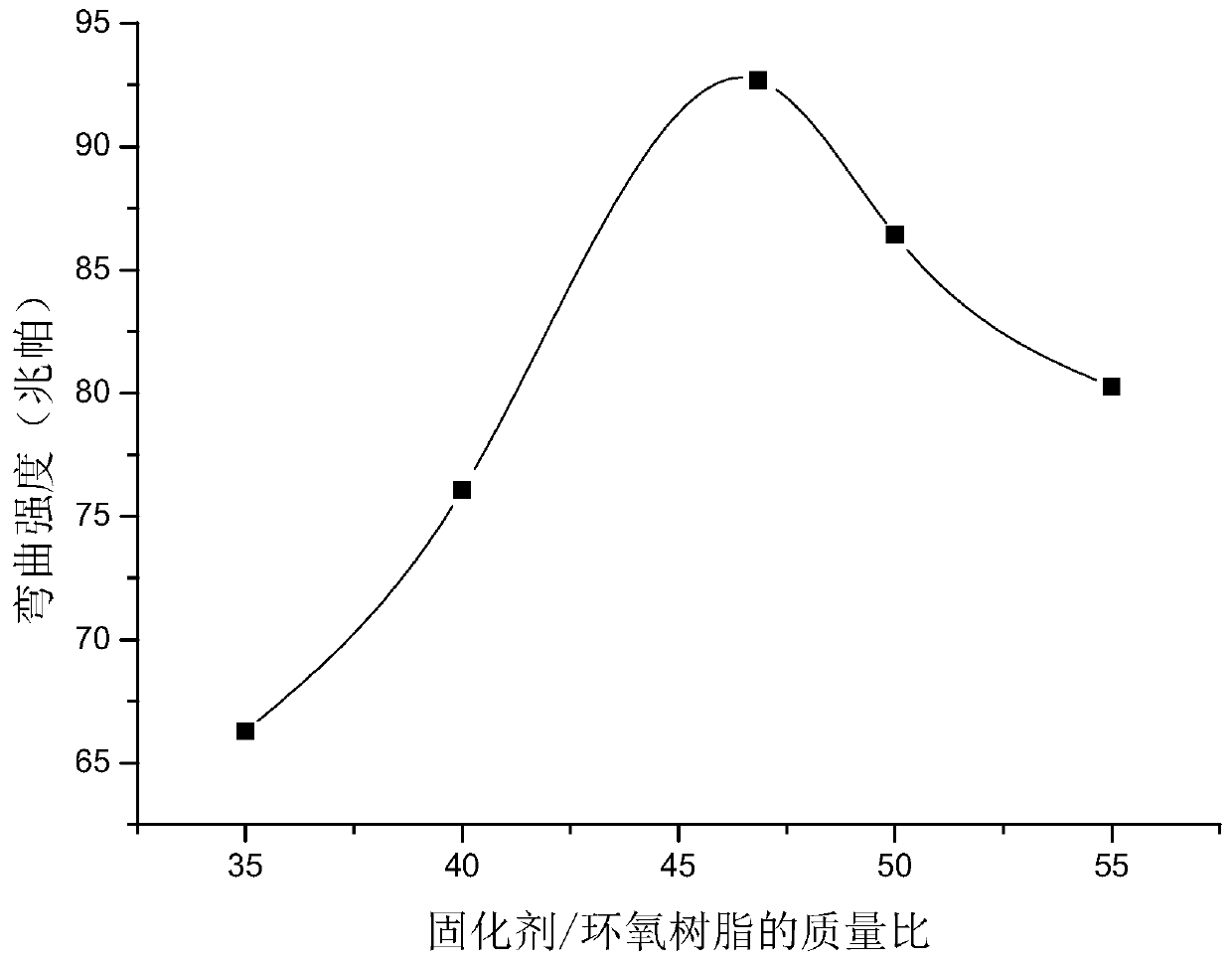

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com