Package sorting method based on speed matching principle

A speed matching and wrapping technology, applied in sorting, packaging, etc., can solve the problems of low efficiency of sorting lines, large floor space, and low space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

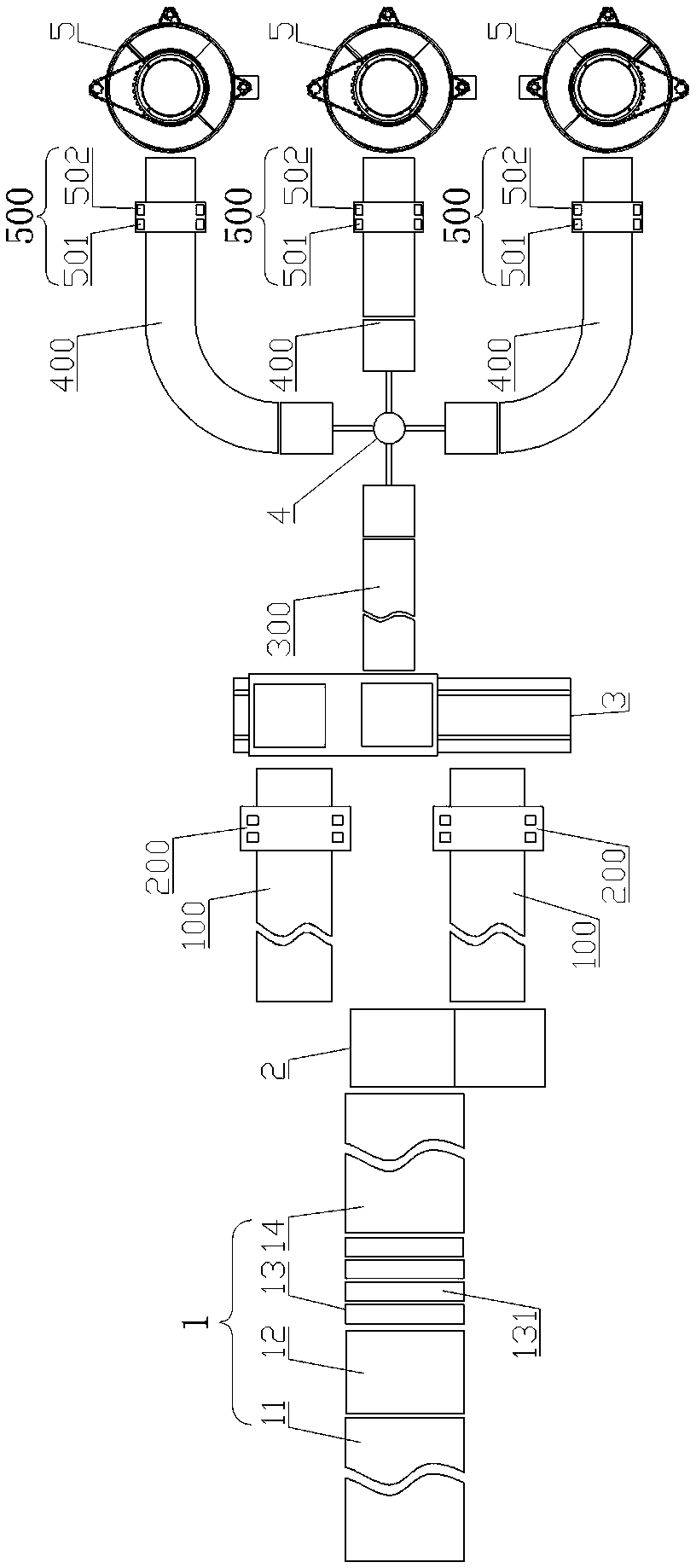

[0122] The package sorting method based on the speed matching principle is applied to the logistics sorting system based on the tower sorting device.

[0123] The logistics sorting system based on the tower sorting device includes a separation device 1, a front diverter 2, a front diverter conveyor 100, a code scanning device 200, a confluence device 3, a confluence conveyor 300, a rear diverter 4, a rear A diversion conveyor 400, an error correction device 500, a tower sorting device and a controller.

[0124] The picking and separating device 1 includes a conveyor A11, a smooth separating plate 12, a roller conveying device 13, and a conveyor B14 that are adjacently arranged from front to back.

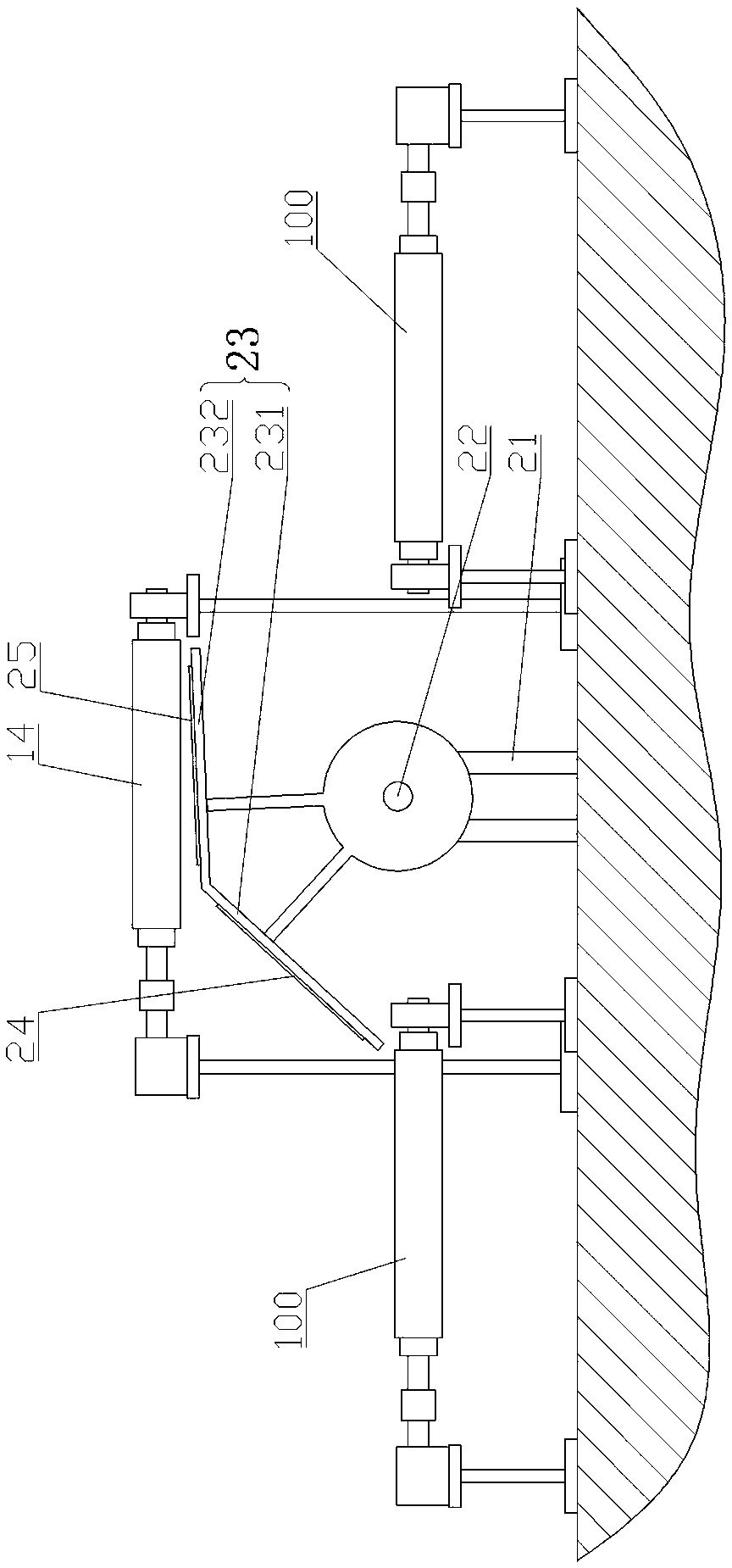

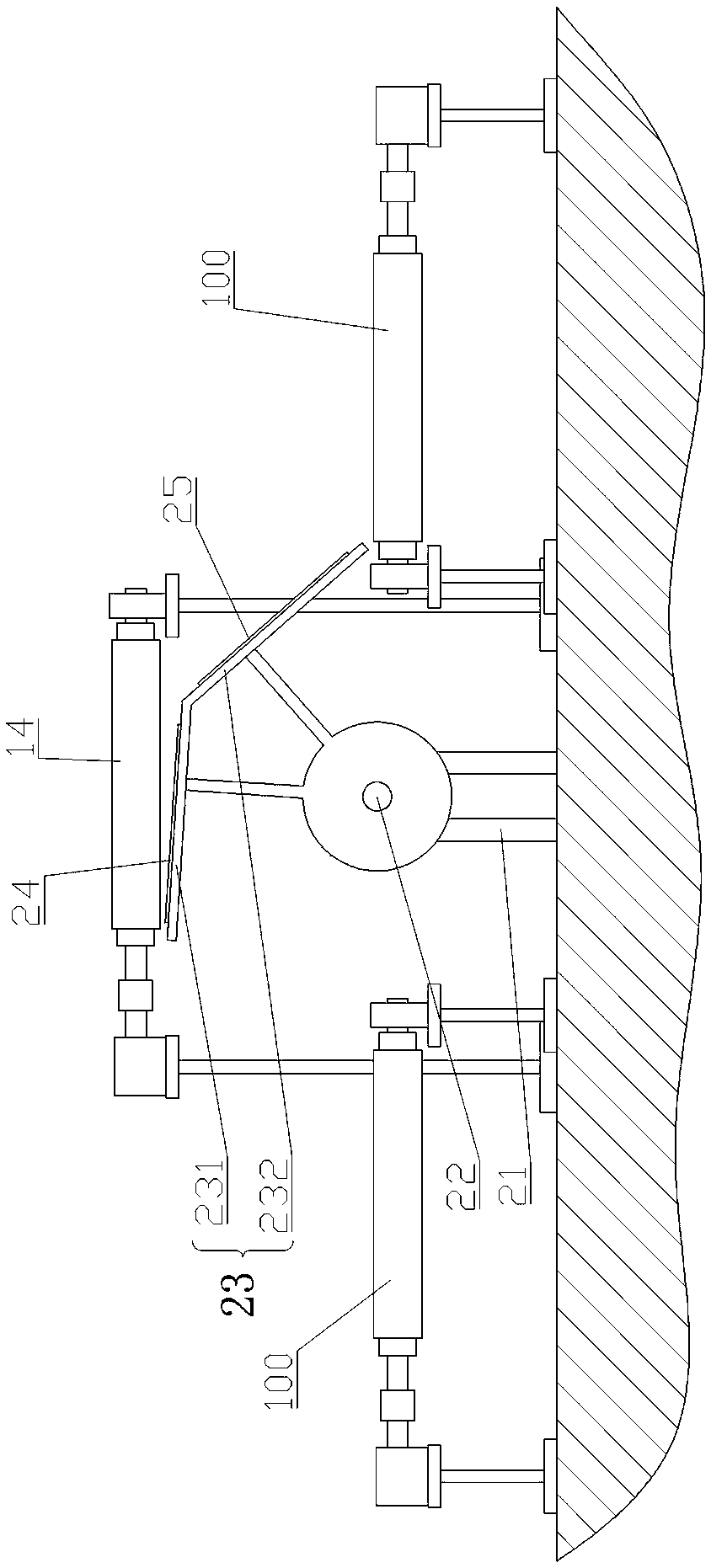

[0125] The front splitter 2 includes a support frame J21, a drive motor J22, a V-shaped disc 23, a pressure sensor J24 and a pressure sensor K25. A first surface 231 and a second surface 232 are formed on the upper end of the V-shaped disk 23 .

[0126] The combiner 3 includes a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com