Three-dimensional turret express sorting system

A sorting system and three-dimensional technology, applied in sorting, conveyors, conveyor objects, etc., can solve the problems of high error rate of manual sorting, large floor space, complex structure, etc., to maximize space utilization, The effect of reducing the floor space and reducing the rate of sorting errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

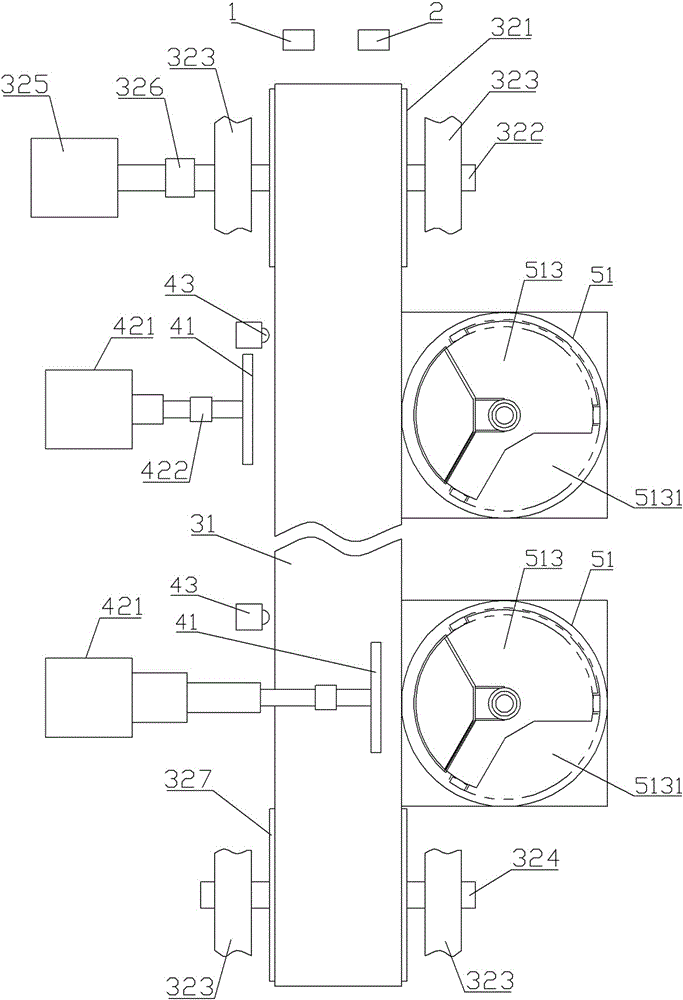

[0038] Such as Figure 1-6 As shown, the three-dimensional turret express sorting system includes a main control computer 1, a package information input device 2, a conveyor belt device, a package pushing device and a turret sorting device.

[0039] The package information entry device 2 is a gun electrically connected to the main control computer 1 . The Barcode scans the barcode on the parcel to obtain the destination information of the parcel, and transmits the scanned data to the main control computer 1 .

[0040] The conveyor belt device includes a conveyor belt 31 and a driving mechanism A for driving the conveyor belt to run. The driving mechanism A includes a main pulley 321 , a main pulley shaft 322 , a positioning frame 323 , a slave pulley shaft 324 , a motor A325 , a coupling A326 and a slave pulley 327 . The main pulley 321 is fixedly connected on the main pulley shaft 322, and the two ends of the main pulley shaft 322 and the slave pulley shaft 324 are all inst...

Embodiment 2

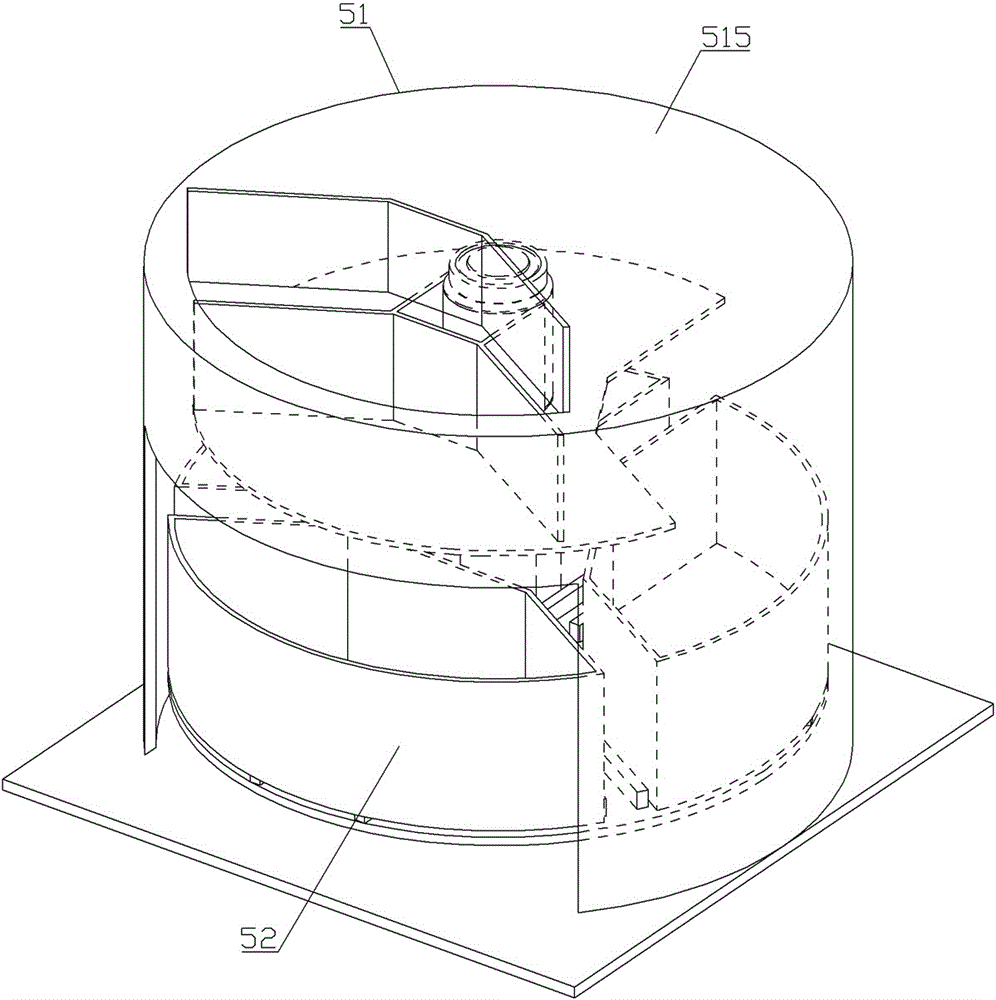

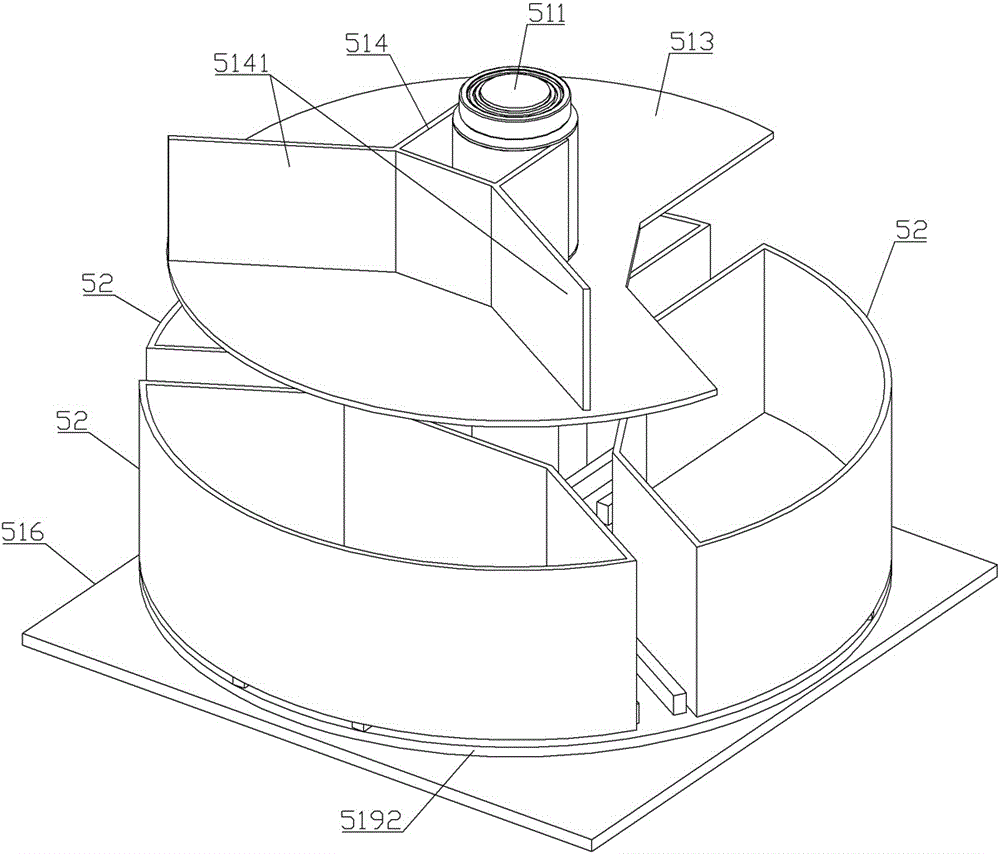

[0075] Such as Figure 7 , 8 As shown, compared with Embodiment 1, the present embodiment differs only in that:

[0076] The parcel receiver consists of a secondary sorter 53 and a plurality of parcel collection bins 52 . The top of the outer cover of the secondary sorter 53 is provided with a parcel inlet, and the lower end of the outer cover of the secondary sorter 53 is provided with a plurality of parcel outlets. The parcel collection box 52 is a box with an upper end opening, which is arranged in the outer cover of the secondary sorter 53 and faces the parcel exit. The upper end of the inner wall is provided with a parcel ultra-high sensor that is electrically connected to the main control computer 1 or communicates. device. The cross-section of the parcel collection box 52 is fan-shaped, and four parcel collection boxes surround the secondary vertical outer rotating shaft 532 in a circle. Each parcel collection box occupies a central angle of 90°.

[0077] In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com