Quick-heating fume-free pan used in sauteing food and making method thereof

A fume-free, quick-heating technology, applied in chemical instruments and methods, special materials for cooking utensils, cooking utensils, etc., can solve problems such as aging, polluting the atmospheric environment, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

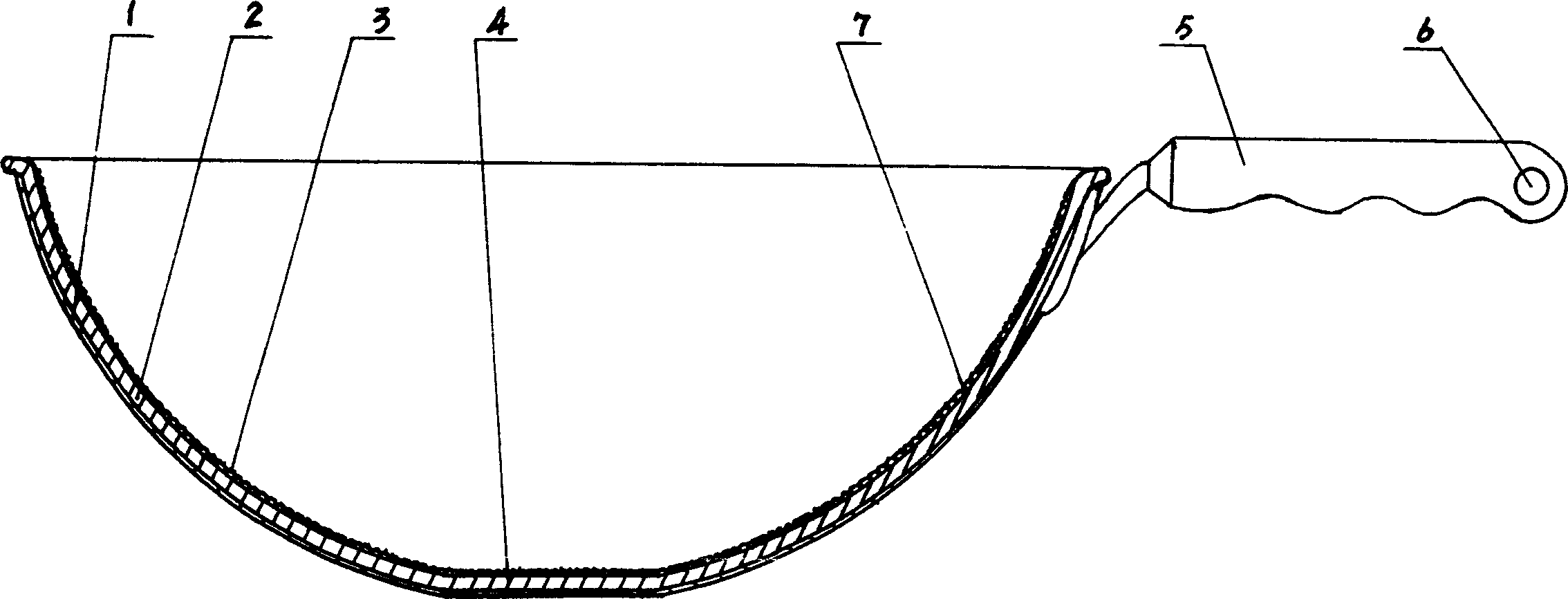

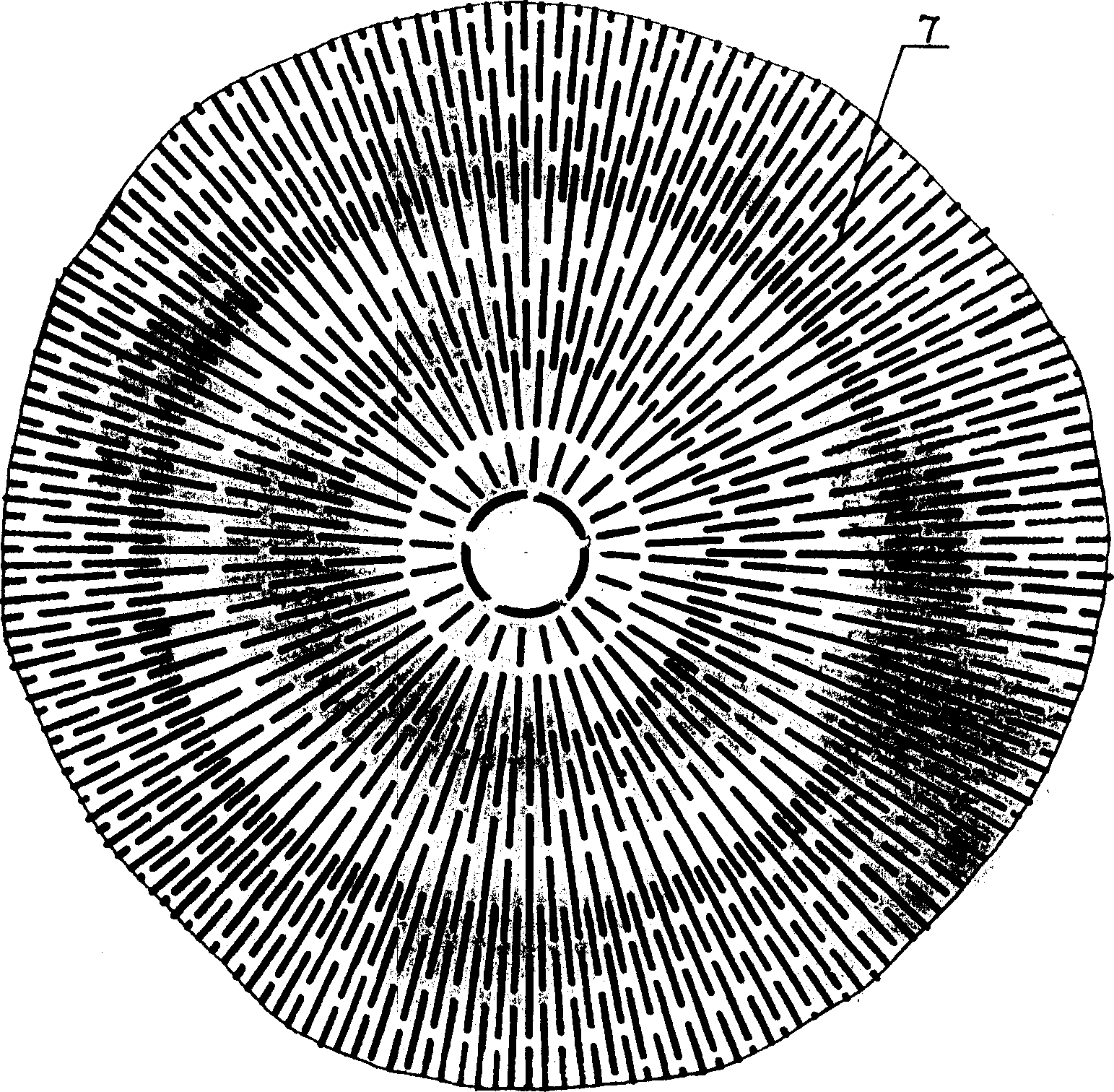

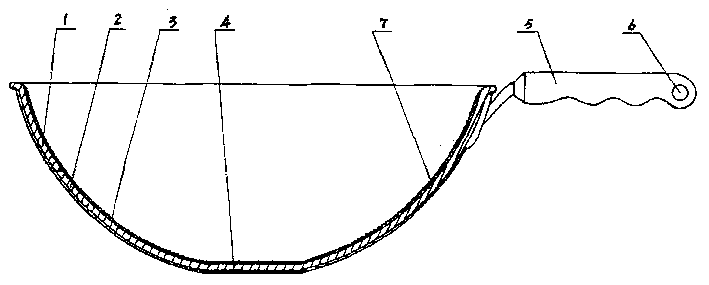

[0013] The present invention determines the embodiment according to the principle that the heat transferred by an object by conduction is proportional to the temperature difference on both sides of the conduction surface of the object and the surface area perpendicular to the heat conduction direction, and inversely proportional to the thickness of the object. figure 1 with figure 2 As shown, it is a specific embodiment of a fast-heating and fume-free frying pan of the present invention, which consists of a pot body 2 and a pot handle 5 fixed on the pot body 2. The inner surface of the pot body 2 is provided with a number of radially small protrusions 7 , and compound the non-stick layer 3 on it, during the cooking process, the shovel only contacts the protrusion 7 on the inner surface of the pot body 2, which will not cause the non-stick layer 3 on the inner surface of the pot to fall off, and the outer surface of the pot body 2 will not be compounded. Adhesive layer or high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com