Photoresist, quantum dot layer patterning method, quantum light-emitting diode (QLED), quantum dot color film and display device

A technology of quantum dot layer and photoresist, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve the problem of destroying quantum dots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

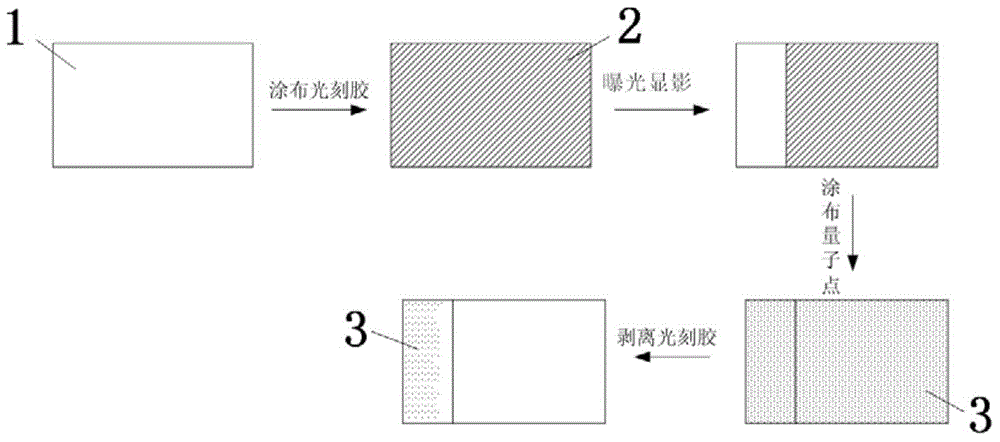

[0048] This embodiment provides a method for patterning a quantum dot layer, comprising the following steps:

[0049] The step of forming a photoresist material layer on the substrate, the step of patterning the photoresist, and the step of hydrophilically treating the photoresist;

[0050] The step of coating quantum dots;

[0051] a step of removing the quantum dots on the remaining photoresist;

[0052] The step of stripping the photoresist.

[0053] Wherein, the step of forming a photoresist material layer on the substrate, the step of patterning the photoresist, and the step of hydrophilically treating the photoresist, the steps are not limited in sequence;

[0054] The step of hydrophilically treating the photoresist may be performed after forming the photoresist material layer and before patterning, or after forming the photoresist material layer and patterning.

[0055] In the quantum dot layer patterning method of the present embodiment, comprise the step of carryi...

Embodiment 2

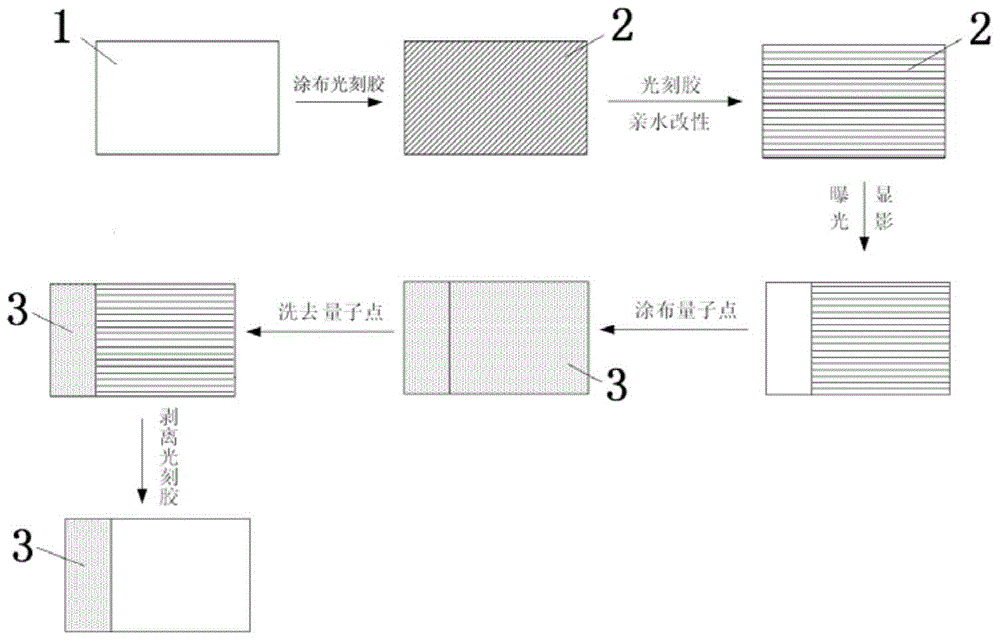

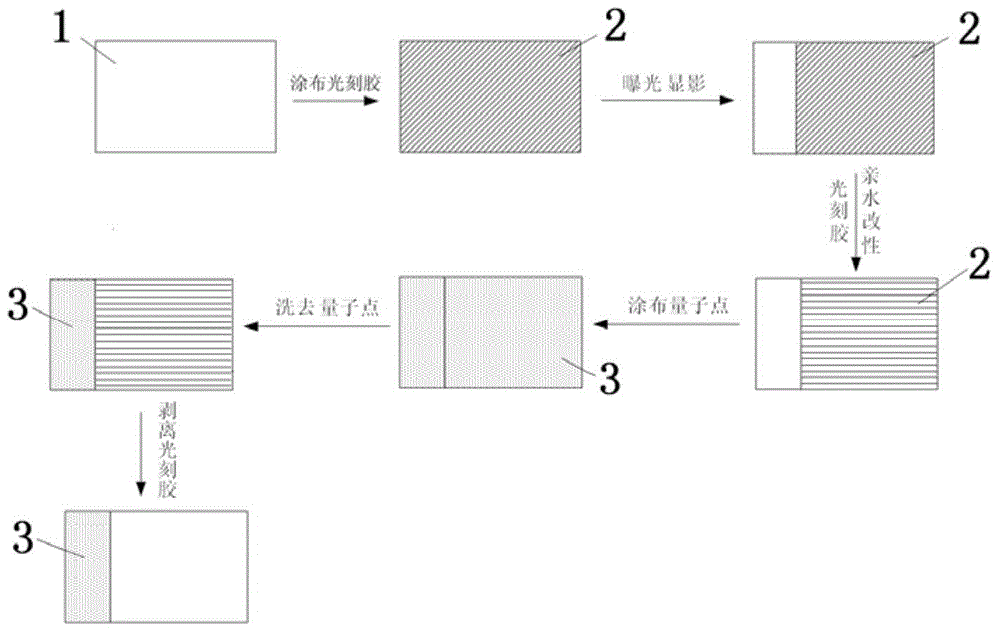

[0057] This embodiment provides a method for patterning a quantum dot layer, such as Figure 2-4 shown, including the following steps:

[0058] A step of forming a photoresist 2 material layer on the substrate 1, a step of patterning the photoresist 2, and a step of hydrophilically treating the photoresist 2;

[0059] The step of coating quantum dot 3;

[0060] a step of removing the quantum dots on the remaining photoresist;

[0061] Step of stripping photoresist 2.

[0062] That is to say, in this embodiment, the photoresist 2 is subjected to hydrophilic treatment to improve the hydrophilic property of the photoresist 2 .

[0063]The schematic diagram of the structure of quantum dot 3 is shown in Figure 4 As shown, the quantum dot 3 is composed of three parts, namely a luminescent core 31, a semiconductor shell 32, and an organic ligand 33; the organic ligand 33 includes a lipophilic group, such as oleylamine CH 3 (CH 2 ) 7 CH=CH(CH 2 ) 7 CH 2 NH 2 , or oleic CH ...

Embodiment 3

[0097] This embodiment provides a photoresist for patterning a quantum dot layer, and the photoresist contains a hydrophilic group.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com