Fume-free pan used in sauteing food and making method thereof

A technology of no oil fume and frying pan, which is applied to special materials for cooking utensils, cooking utensils, household utensils, etc., and can solve the problems of low thermal efficiency and easy peeling of non-stick layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

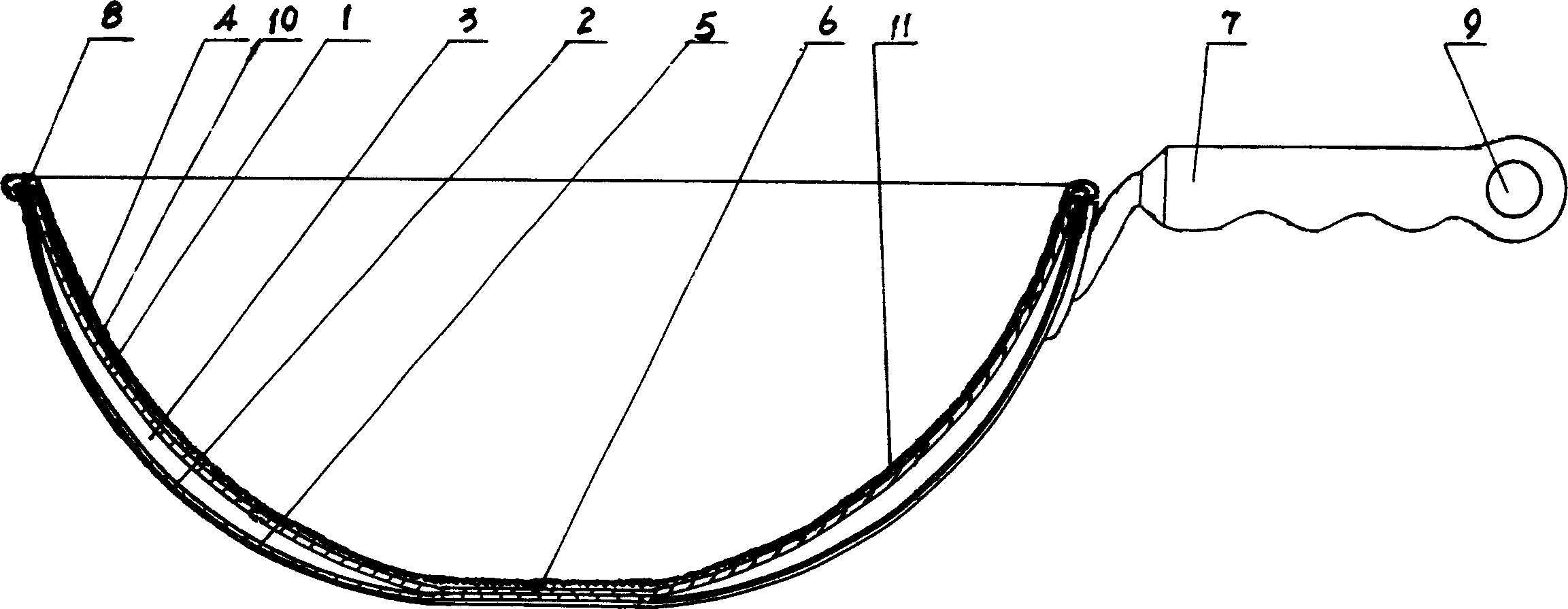

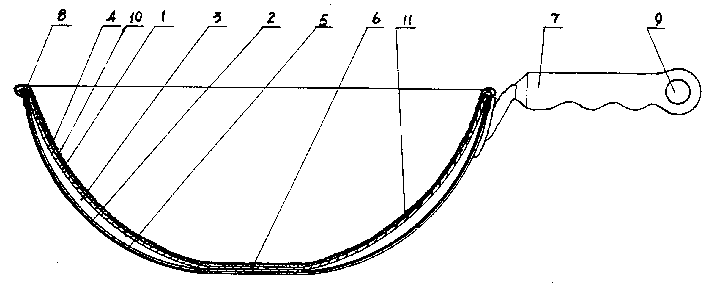

[0013] figure 1 As shown, it is a specific embodiment of a fume-free wok of the present invention, including a pot body composed of an inner pot body 1 and an outer pot body 2, a pot handle 7 fixed on the pot body, the inner pot body 1 and the outer pot body The body 2 is fixedly connected, the bottoms of the inner pot body 1 and the outer pot body 2 are provided with a flat bottom 6 corresponding to each other and combined into one body, a sandwich layer 3 is formed between the pot walls of the inner and outer pot bodies 1 and 2, and the inner pot body The surface of the body 1 is provided with a bottom glaze 10, and the surface of the bottom glaze 10 is provided with a number of tiny unevennesses 4, and a non-stick layer or an enamel layer 11 is arranged on it. It will cause the non-stick layer on the inner surface of the pot to fall off, and the surface of the outer pot body 2 is composited with an enamel layer 5; in order to improve the reliability and overall appearance o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com