Ascending and descending mechanism of 3D printer and ascending and descending method thereof

A technology of 3D printer and lifting mechanism, which is applied to 3D object support structure, additive manufacturing, processing platform/substrate, etc., can solve the problems of unstable lifting movement, inconvenient disassembly and maintenance, nozzle blockage, etc., and achieves fast installation and disassembly efficiency. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

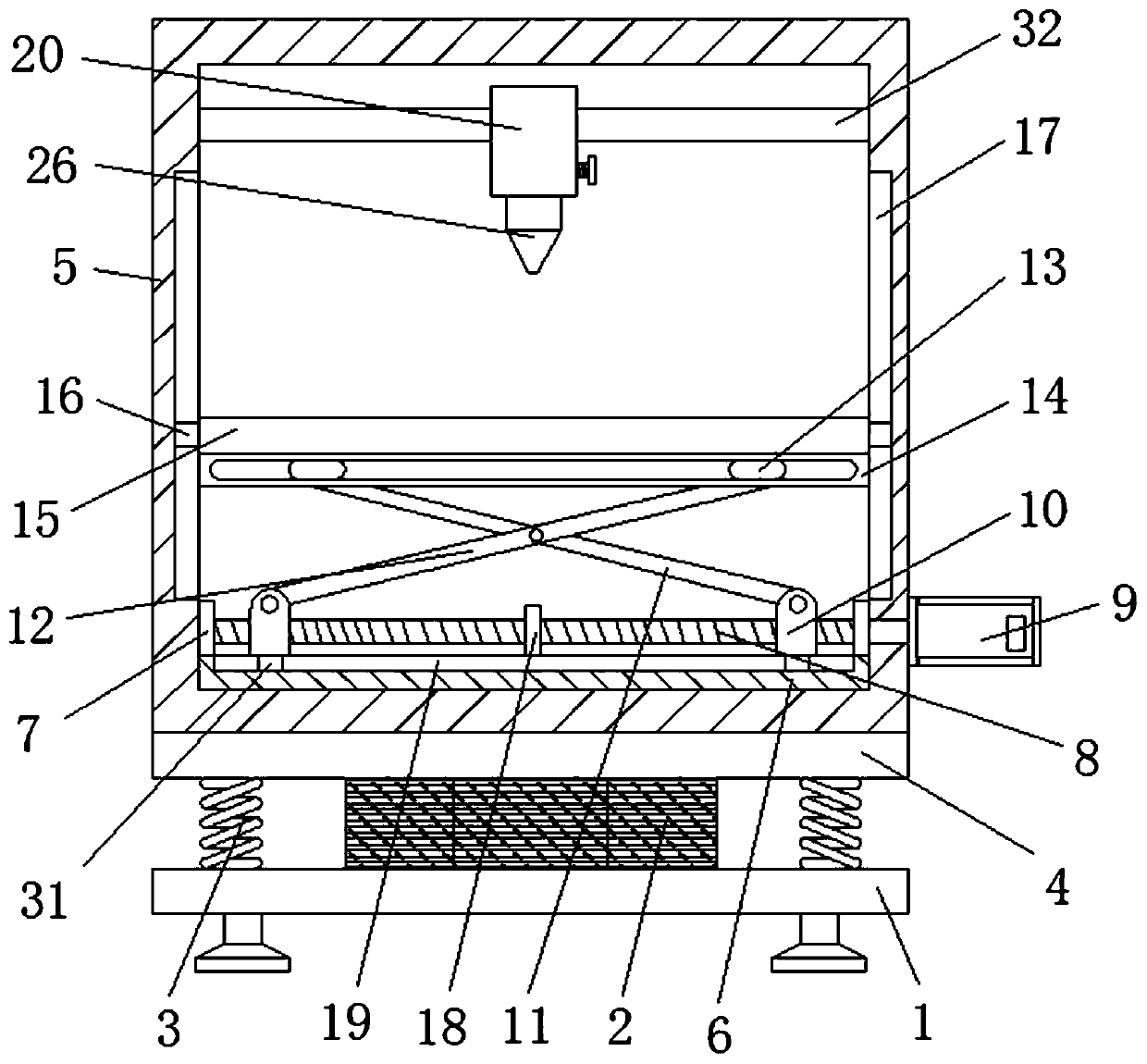

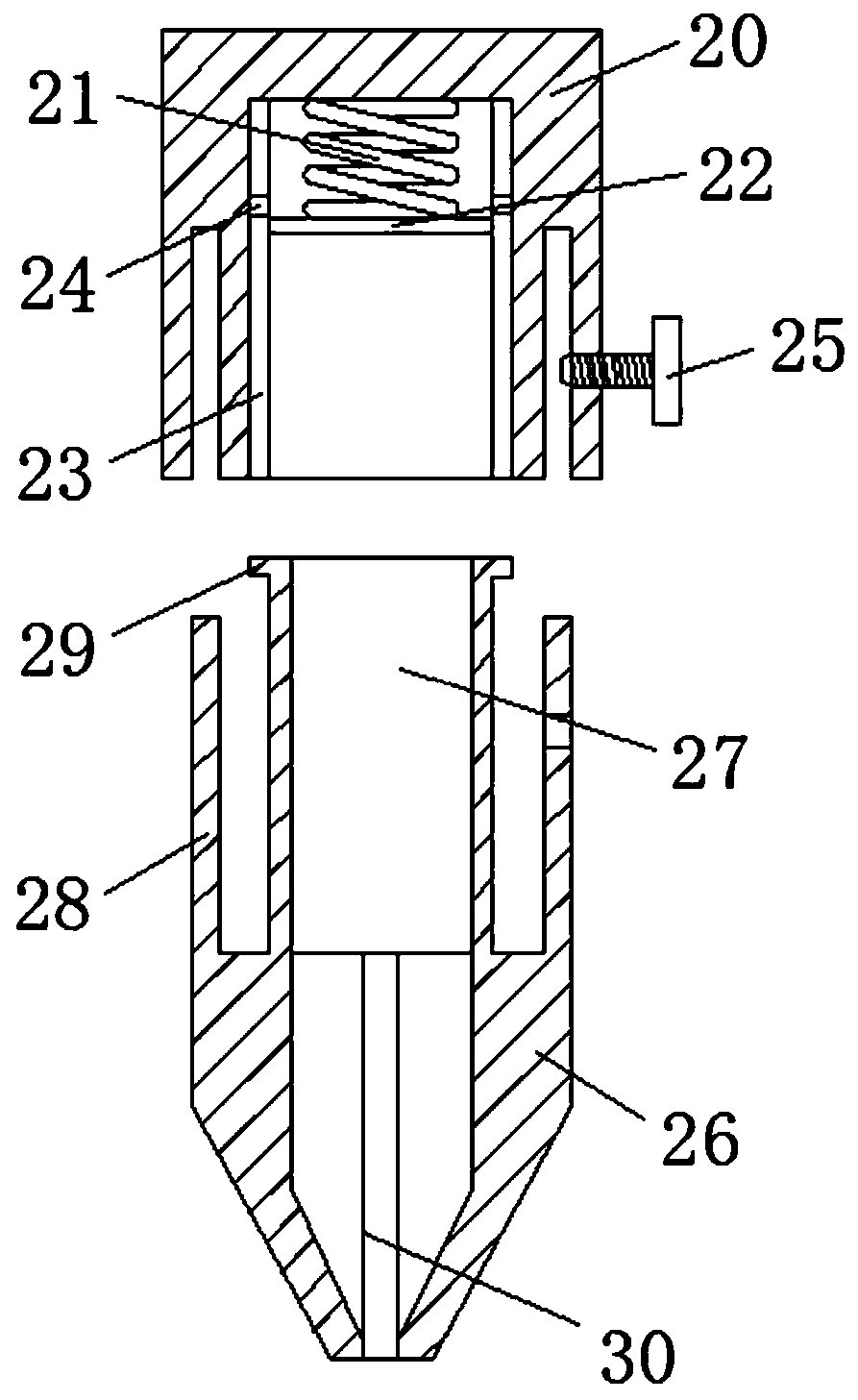

[0032] see Figure 1-5 , this embodiment provides a 3D printer lifting mechanism, including a support base 1, a high-elastic rubber buffer pad 2 is fixedly connected to the middle of the upper surface of the support base 1, and a support plate 4 is fixedly connected to the upper surface of the high-elastic rubber buffer pad 2 A damping spring 3 is fixedly connected between the support plate 4 and the support seat 1, the upper surface of the support plate 4 is fixedly connected with the printing chamber 5, and the inner lower surface of the printing chamber 5 is fixedly connected with the fixed plate 6, and the two sides of the fixed plate 6 Both ends are fixedly connected with a rotating seat 7, and the rotating seat 7 is connected with a threaded mandrel 8, and one side of the printing chamber 5 is fixedly connected with a motor 9 at a position corresponding to the threaded mandrel 8, and the output end of the motor 9 is fixedly connected with the threaded mandrel 8. The insi...

Embodiment 2

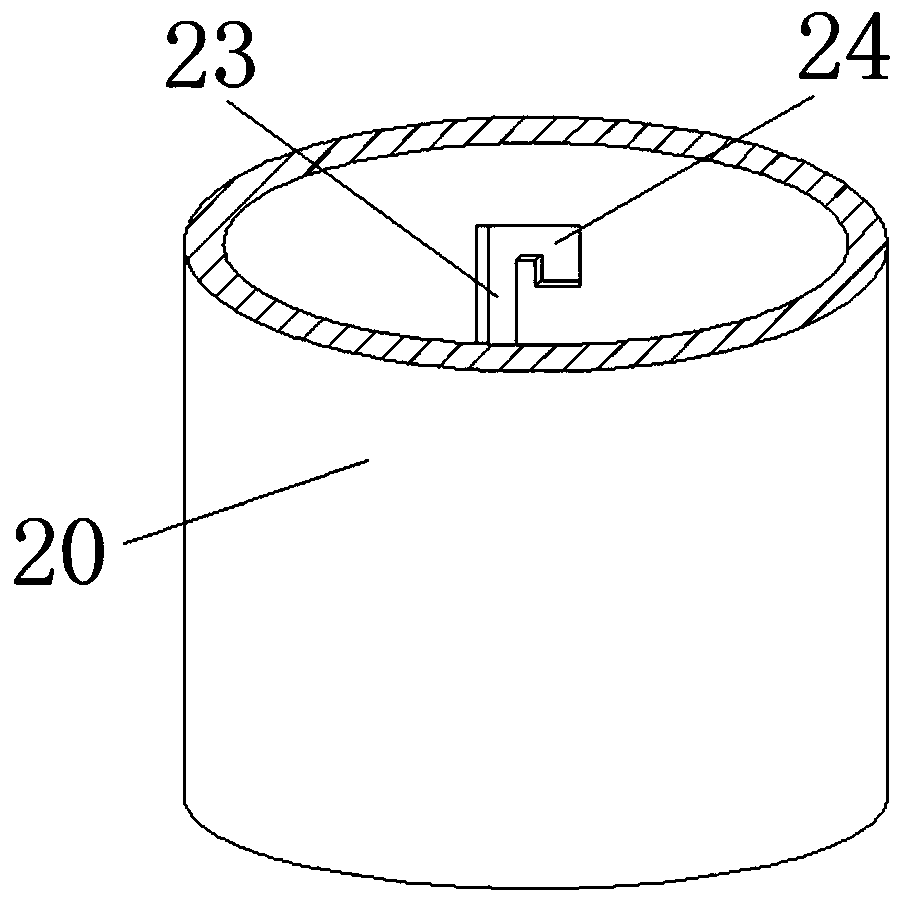

[0035] see Figure 1-5 , a further improvement has been made on the basis of Embodiment 1: the outer wall of the middle part of the screw rod 8 is fixedly connected with a limit block 18, and through the setting of the limit block 18, the sliding seat 10 is effectively restricted, avoiding the sliding seat 10. Damage occurs due to touch, the thread directions of the two sliding seats 10 are opposite, and the setting of the two sliding seats 10 with opposite thread directions facilitates the movement of the sliding seats 10 and the lifting of the printing platform 15, and the shock absorbing spring 3 is arranged as Four, four damping springs 3 are in a rectangular row. The damping springs 3 arranged in a rectangle can effectively damp the printing chamber 5 and buffer the vibration generated when the 3D printer is working. The third chute 23 and the card slot 24 are connected with each other, and the third chute 23 and the draw-in groove 24 form an L-shaped structure, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com