Coiled laminate square lithium-ion battery cell and preparation method thereof

A lithium-ion, wound-type technology, applied in the direction of circuits, electrical components, secondary batteries, etc., can solve the problems of electrode material falling off, lower battery performance, and smaller capacity, so as to improve performance and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment, the present invention is further described:

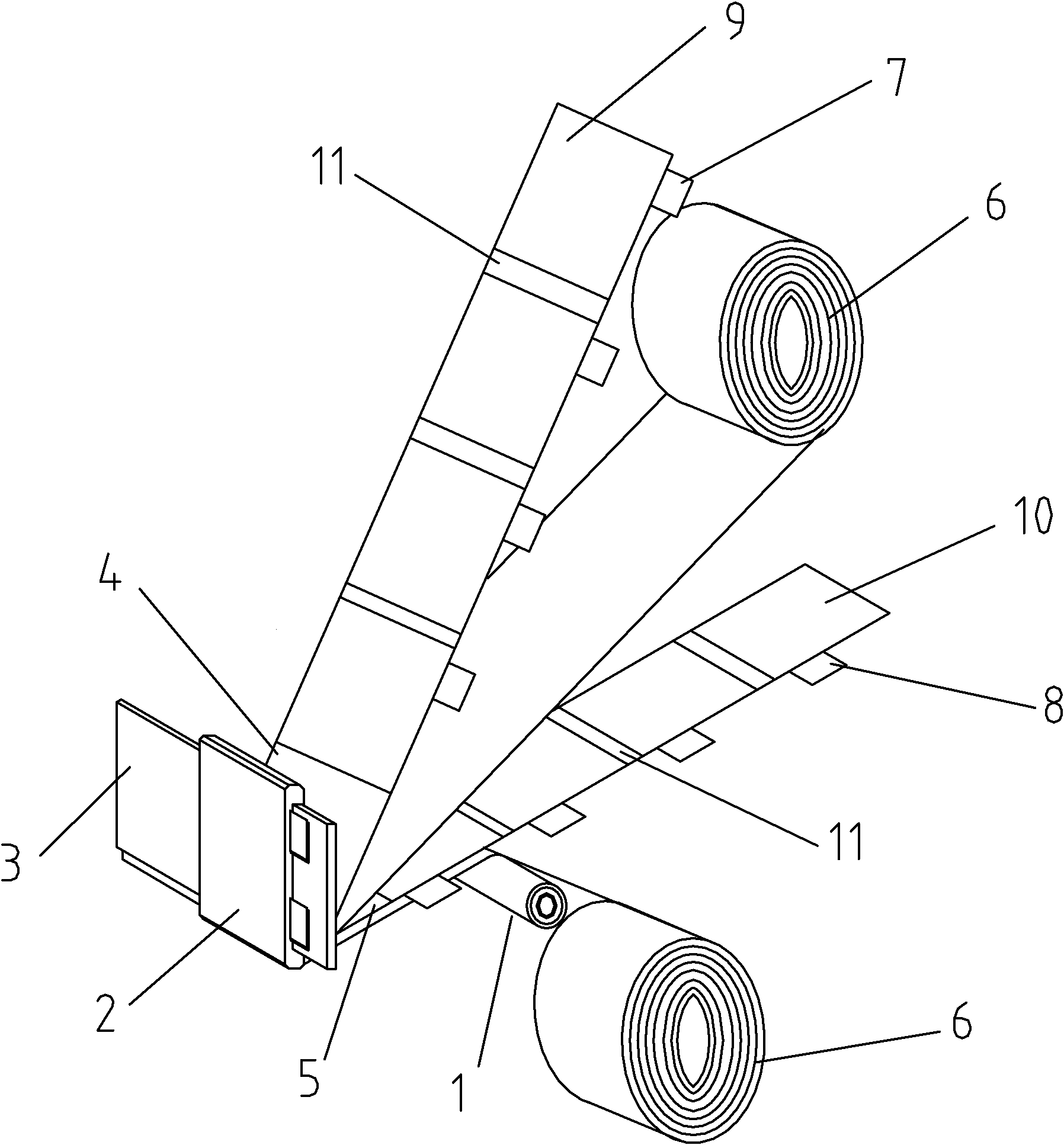

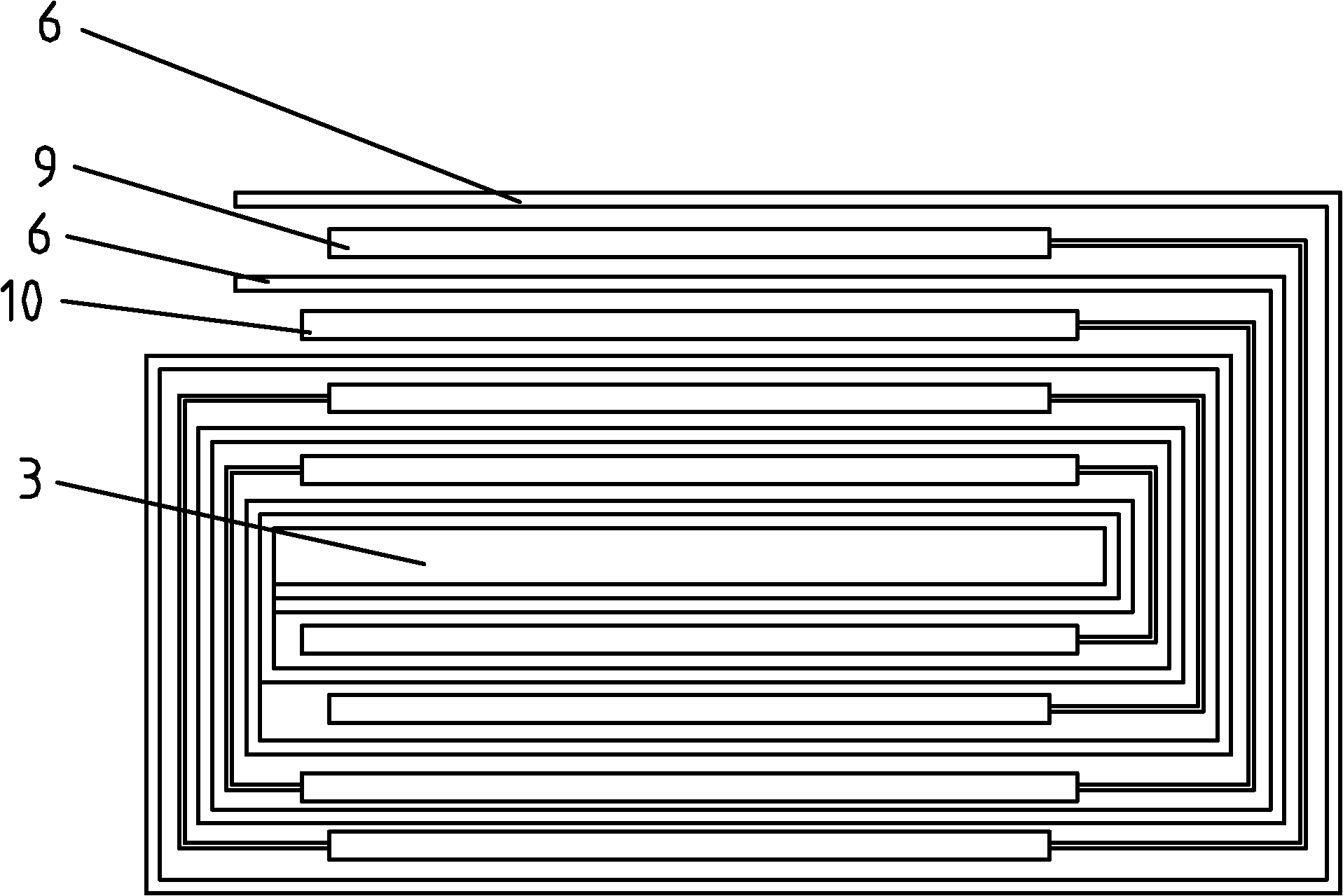

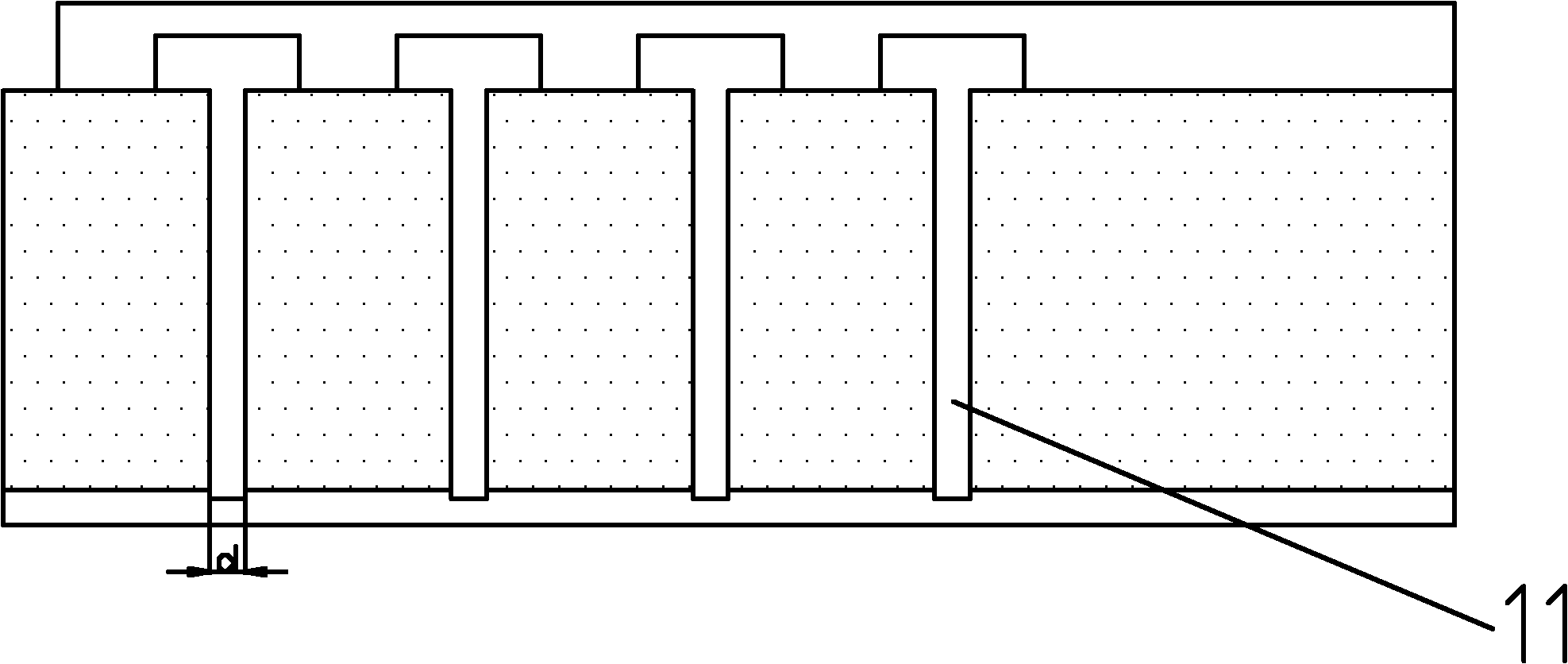

[0027] Such as figure 1 , 2 The illustrated embodiment of the wound-type stacked square lithium-ion battery core of the present invention includes a plate-shaped square winding needle 3, and a strip-shaped pole piece is wound on the winding needle 3; the pole piece includes a strip-shaped base layer , the surface of the base layer is coated with electrode material. The pole piece includes a coating area of electrode material and an isolation area 11 for disconnecting the coating area. The isolation area 11 is located on the pole piece wound on both sides of the winding needle 3, and the scope of the isolation area 11 includes the entire winding The pole pieces on both sides of the winding needle 3.

[0028] The pole piece includes a positive pole piece 4 and a negative pole piece 5, and the positive pole piece 4 and the negative pole piece 5 are stacked and wound on the win...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com