Adjustable wrench

A wrench head and transmission mechanism technology, applied in the field of wrench heads, can solve the problems of wrench loss of function, uneven force, screw detachment, etc., and achieve the effect of high overall strength and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

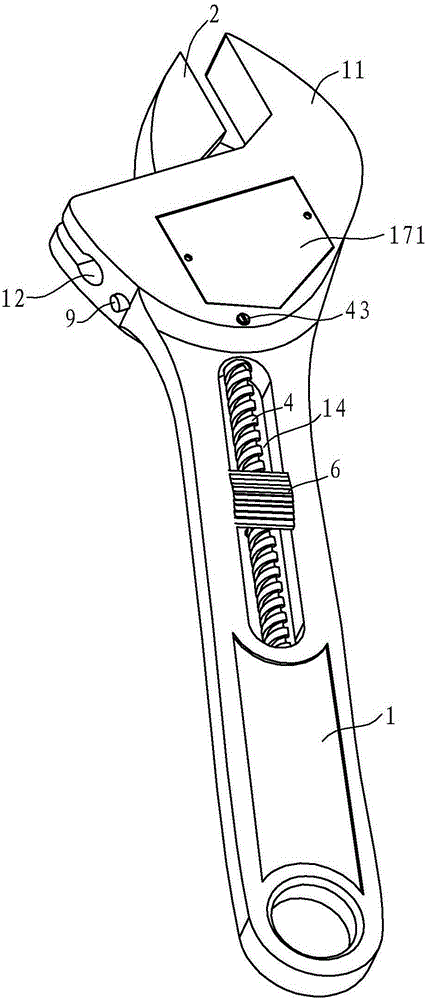

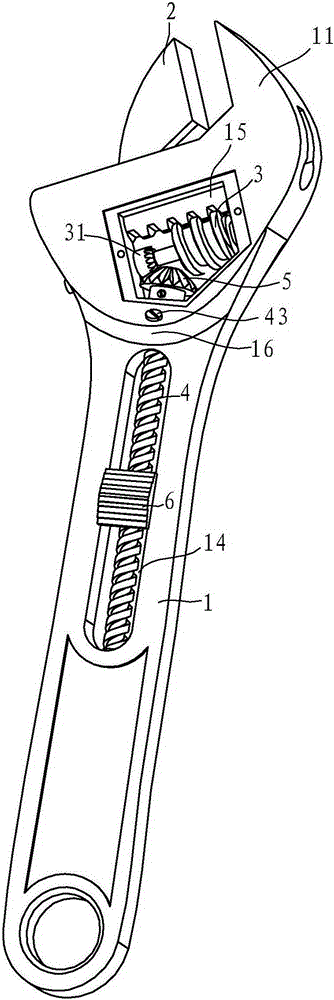

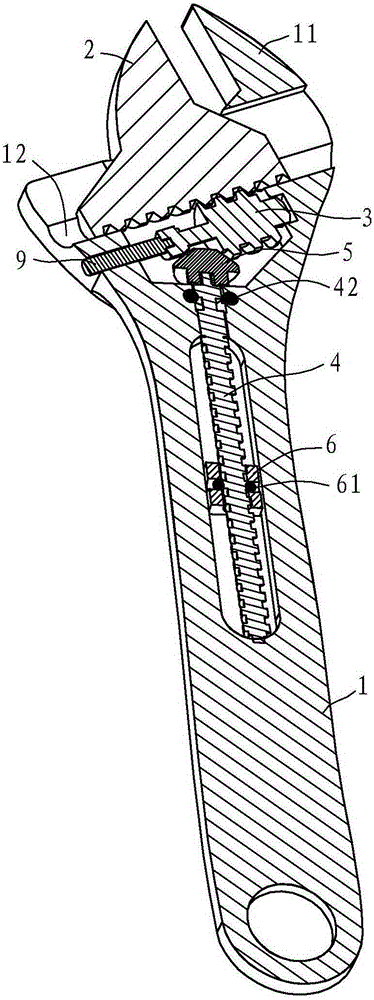

[0036] Example 1, such as Figure 1 to Figure 6 As shown, the adjustable wrench in this embodiment includes a handle 1 , an adjustable wrench lip 2 , a transmission mechanism and a screw rod 4 .

[0037] The front end of the handle 1 is extended with a lever lip 11 and has a mounting cavity 15. The handle 1 is formed with a chute 12 near the lever lip 11; the handle 1 is provided with a strip-shaped hole 14 along the length direction, and the front end of the strip-shaped hole 14 is A partition 16 is formed between the mounting cavity 15 . The port of the installation cavity 15 is provided with a cover plate 17 capable of covering the transmission mechanism and the bevel gear 5 .

[0038] The transmission mechanism is located in the installation cavity 15 , specifically: the transmission mechanism includes a worm 3 and a bevel gear 31 , the bevel gear 31 rotates coaxially with the worm 3 and meshes with the bevel gear 5 for transmission. The worm 3 is arranged in the install...

Embodiment 2

[0046] Example 2, such as Figure 7 and Figure 8 As shown, the transmission mechanism in this embodiment includes a worm 3, a first gear 32 and a second gear 30, and the first gear 32 rotates coaxially with the worm 3; Gear teeth 33 and bevel teeth 34 meshed with bevel gear 5 for transmission. The handle 1 is provided with a strip-shaped slot 17 along the length direction, and a partition 16 is formed between the front end of the strip-shaped slot 17 and the installation cavity 15 . Refer to Example 1 for other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com