Cleaning fixture

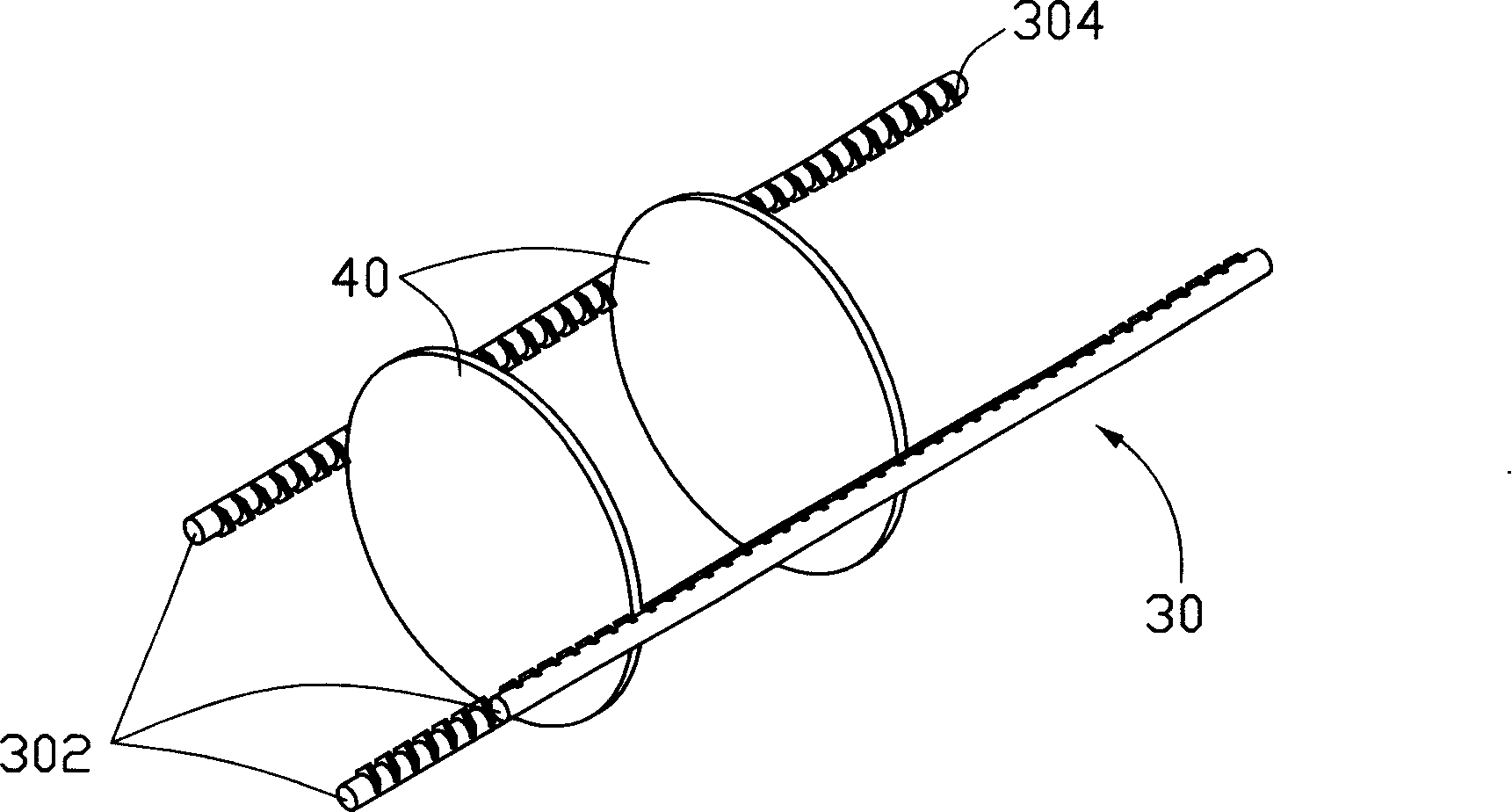

A cleaning fixture and step-shaped technology, which is applied to cleaning methods and tools, manufacturing tools, cleaning flexible objects, etc., can solve the problems that the optical component 40 is difficult to put in, the optical component 40 cannot bear, and is difficult to take out, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

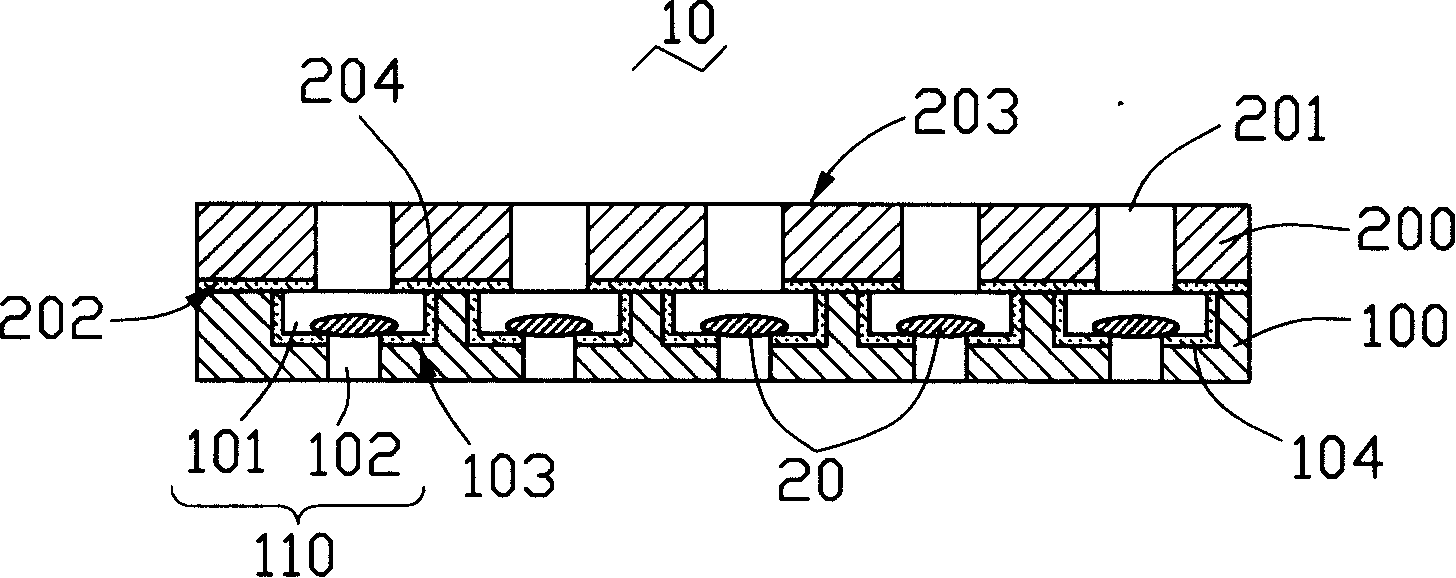

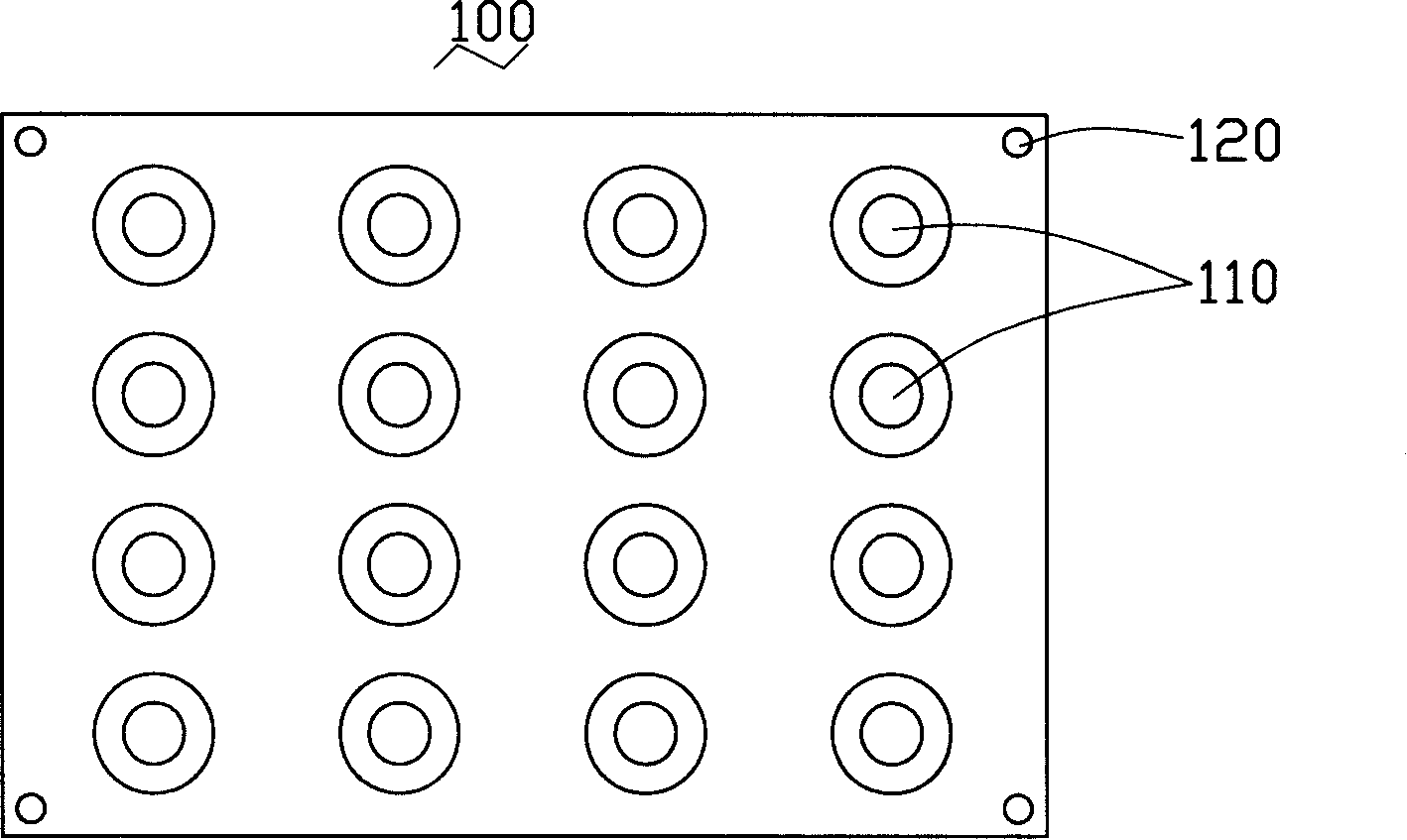

[0022] see figure 2 , the first embodiment of the present invention provides a cleaning jig 10 for cleaning optical components, the cleaning jig 10 includes a carrier plate 100 and a cover 200 .

[0023] There are a plurality of stepped through holes 110 on the carrier plate 100, and the stepped through holes 110 include an accommodating portion 101 and a communicating portion 102, the aperture of the accommodating portion 101 is larger than the aperture of the communicating portion 102, and the A step 103 is formed at the junction of the two. The accommodating portion 101 is used for accommodating the optical assembly 20, and the communicating portion 102 can allow the water flow to contact the optical assembly 20 accommodated in the accommodating portion 101 during the cleaning process of the optical assembly 20, thereby cleaning the optical assembly 20. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com