Repairing technology for ultrasound rolling strengthening of shaft type component surface laser cladding layer

A technology of ultrasonic rolling and laser cladding, which is applied in the coating process and coating of metal materials, can solve the problems of poor surface fatigue performance, and achieve the effects of improving fatigue performance, simple operation, and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

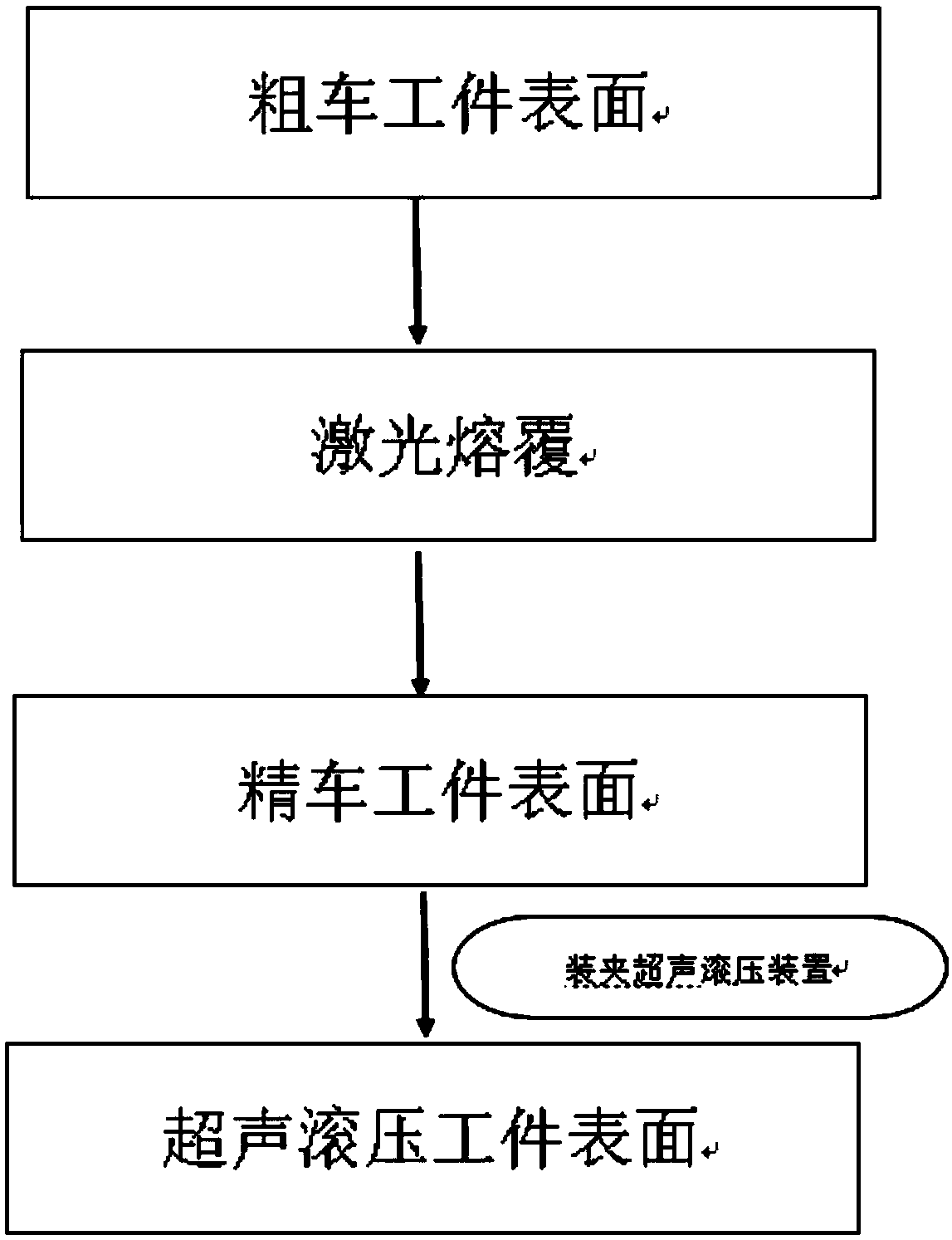

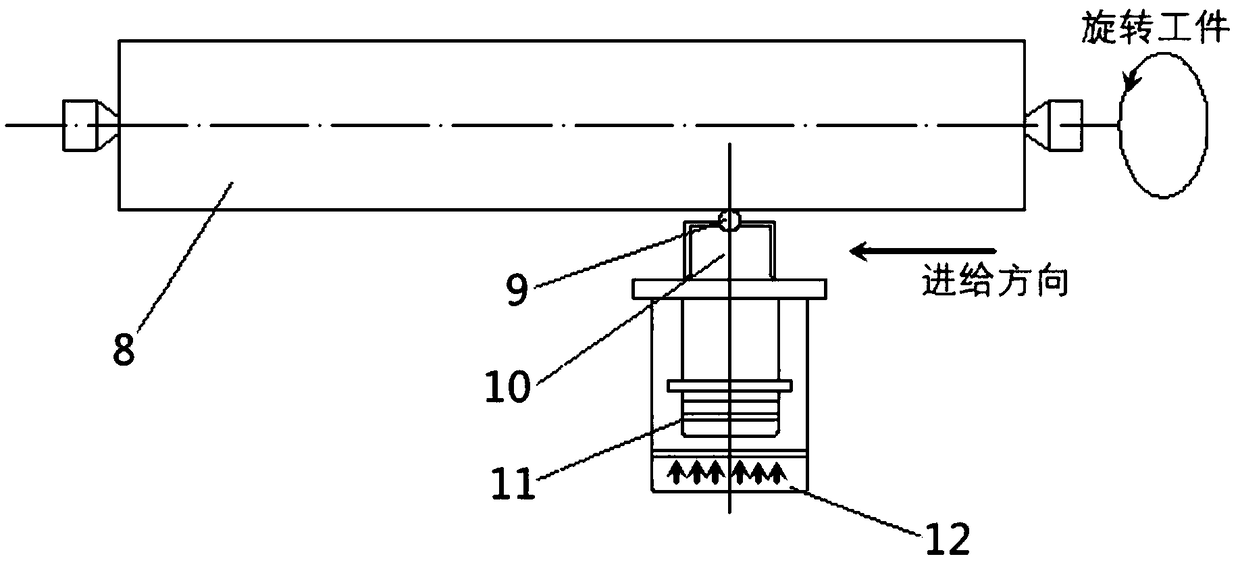

[0035] Embodiment 1 provides a repair process for ultrasonic rolling to strengthen the laser cladding layer on the surface of shaft parts:

[0036] In the embodiment of the present invention, the object to be repaired is a kind of stirring shaft of mining machinery. Cr≤0.25, Ni≤0.30Cu≤0.25; obvious wear can be seen on the surface.

[0037] Specifically follow the steps below:

[0038] S1, carry out the first turning process (rough turning) on the outer circle surface of the shaft to be repaired, remove a certain amount of outer circle surface layer; carry out rough turning on the outer circle surface of the shaft to be repaired, and the rough turning speed is 180-220r / min , the feed rate is 0.3-0.5mm / r, and the cutting rate is 0.3-0.5mm;

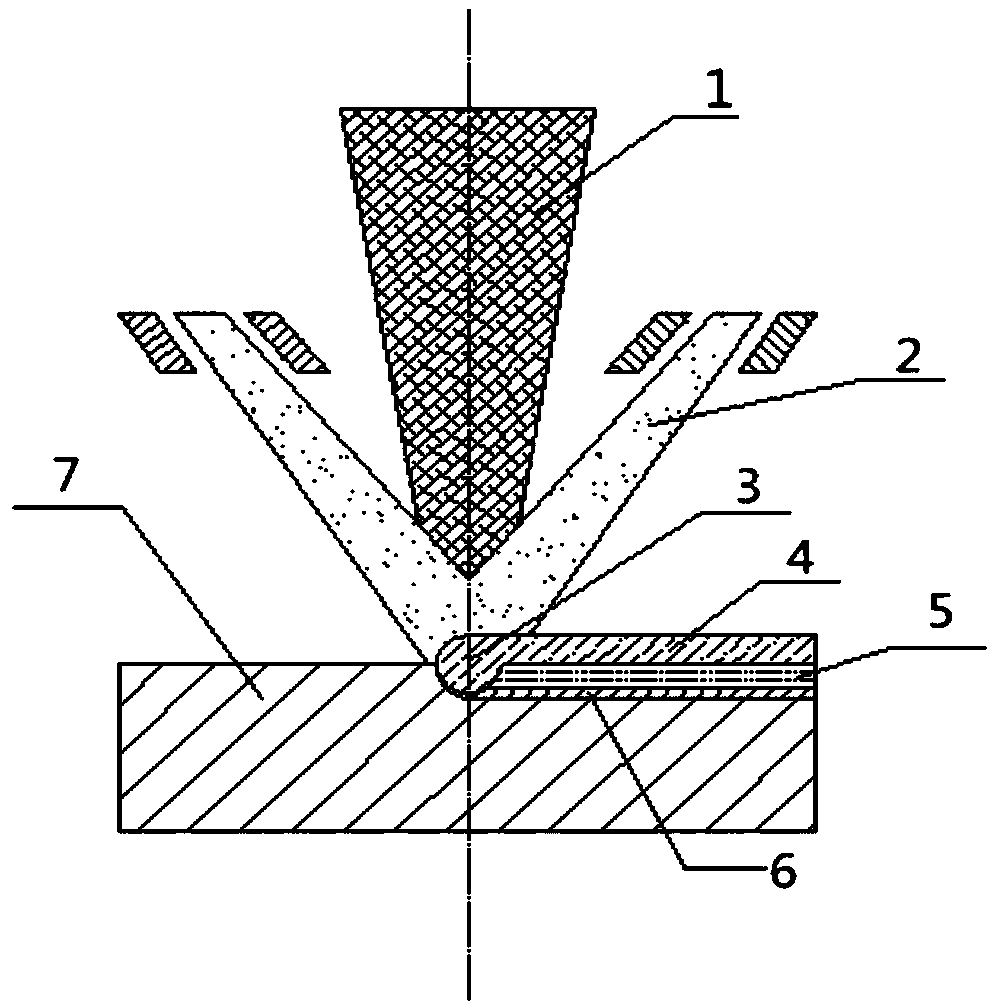

[0039] S2, laser cladding, the thickness of laser cladding can be adjusted according to the specific requirements; Covering thickness, if you need to change the powder feeding amount, you can adjust it by the above two parameters), the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com