Dendriform water in-out system of filter press filter plate

A technology of filter plate and water outlet system of a filter press, applied in the field of filter press, can solve problems such as failure of a single branch pipeline, pipeline collapse, collapse and ejection, etc., so as to improve reliability and service life, and increase reliability and increase , to prevent the effect of accidental failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

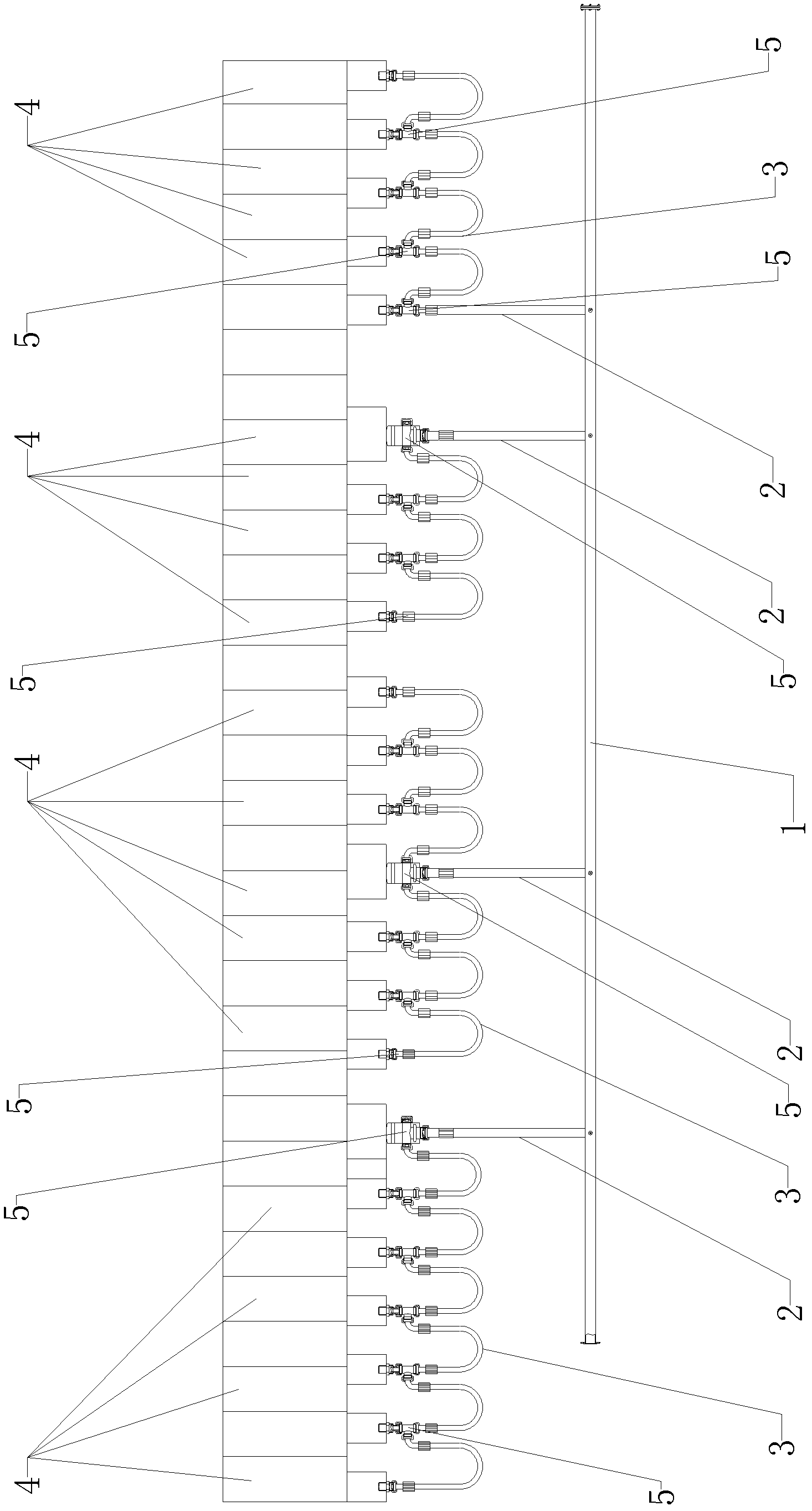

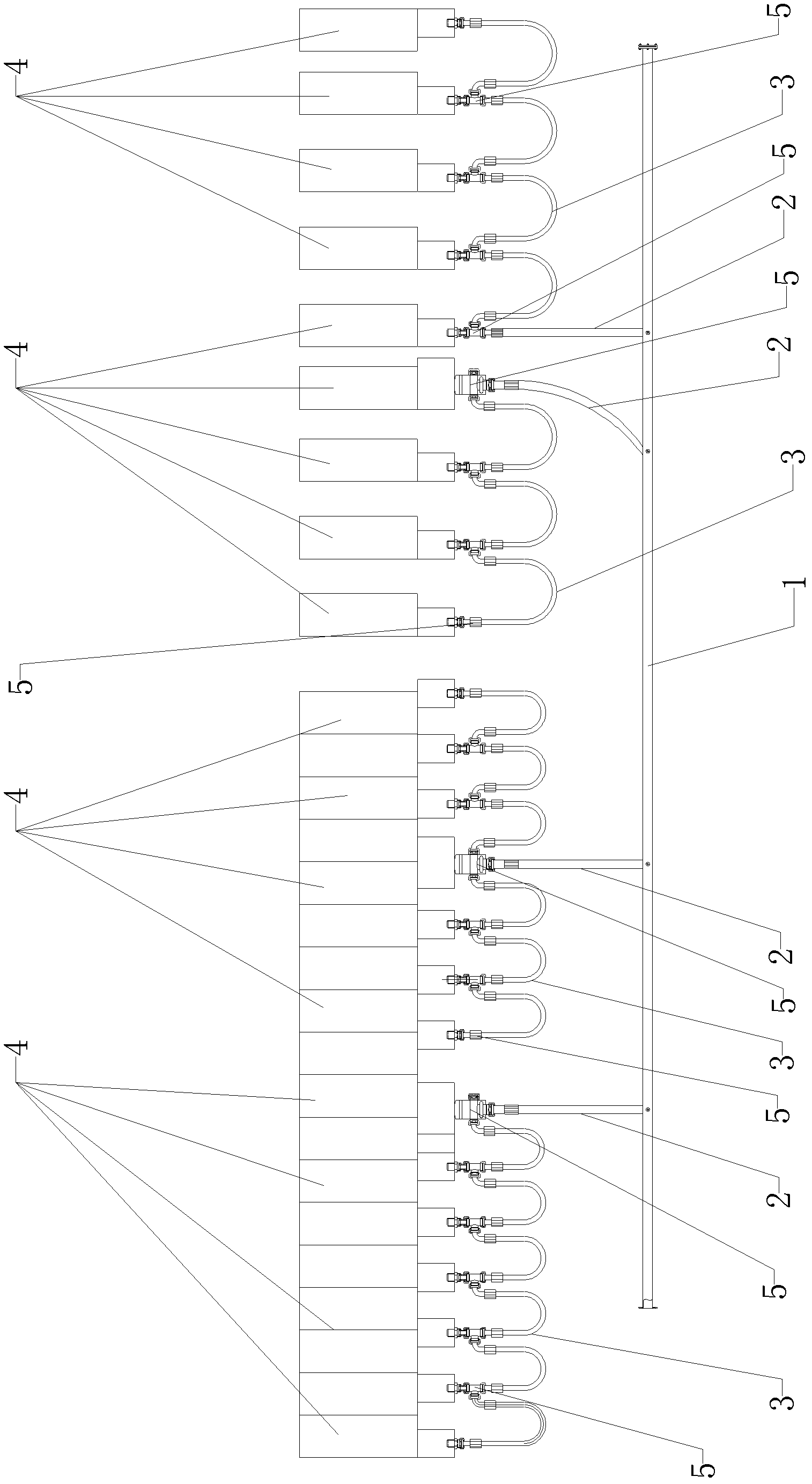

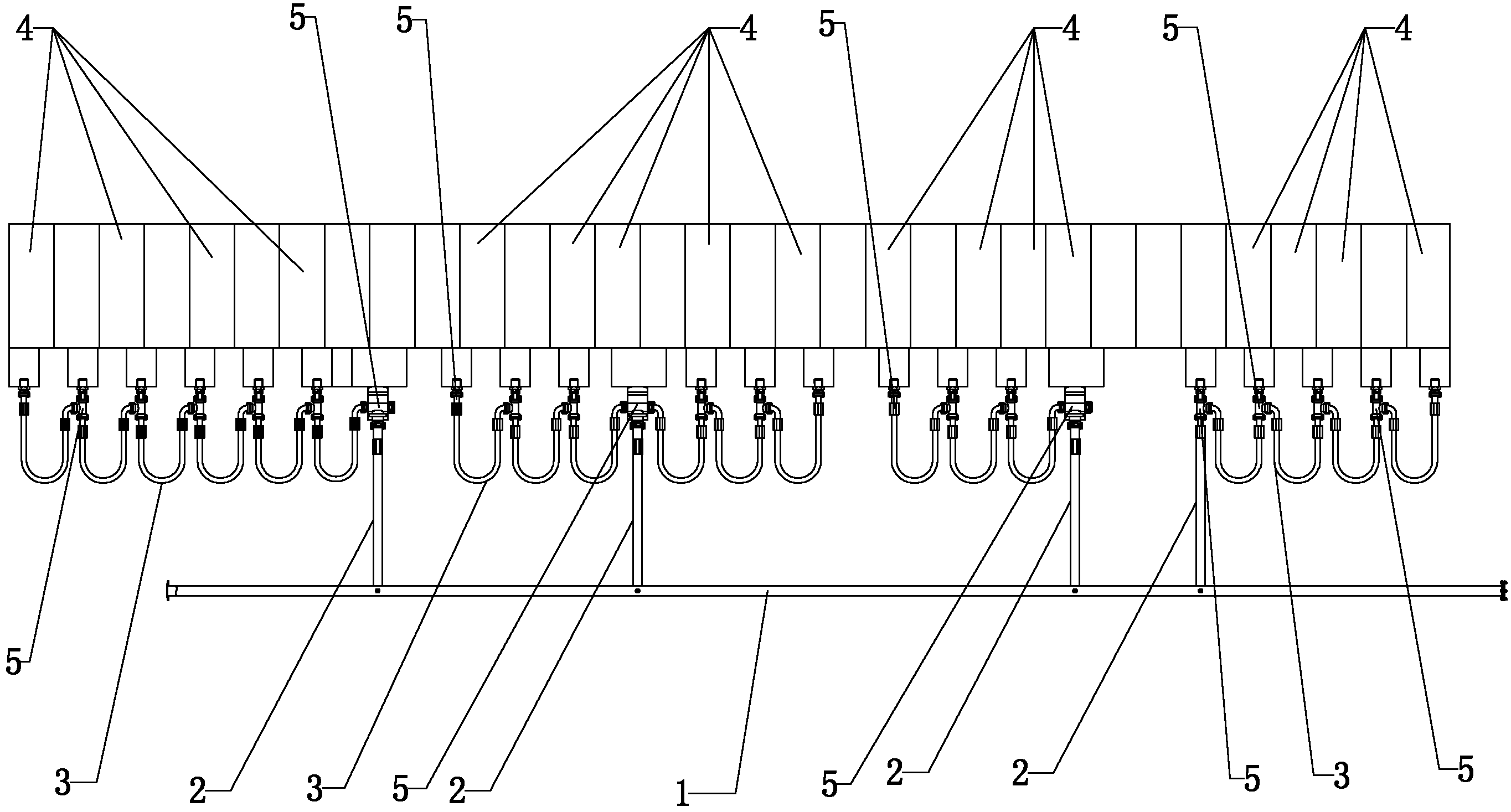

[0015] like Figure 1-2 As shown, a filter press filter plate pressing tree-shaped water inlet and outlet system according to the embodiment of the present invention is composed of a main main pipe 1, several main branch main pipes 2 and branch pipes 3, and is characterized in that: the main branch main pipes 2 and The branch pipes 3 form a tube bundle, and the tube bundle and the main main pipe 1 form a tree-like water inlet and outlet system. One end of the water inlet and outlet system is connected to the filter plate 4 of the filter press, and the other end of the water inlet and outlet system is connected to the external water supply and outlet system. Drainage connection; several main branch supervisors 2 are distributed at intervals between the main main pipe 1 and the filter plate 4 of the filter press; branch pipes 3 are arranged on one or both sides of the main branch supervisor 2, and the main branch supervisors 2 and corresponding branch pipes 3 form a tube bundle. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com