Yarn guide device for fiber laying

A yarn guide device and fiber laying technology, which is applied in the processing field of fiber laying, can solve the problems of increasing the volume of winding equipment, limiting the freedom of robot movement, and high equipment costs, so as to save space, reduce costs, and simplify laying The effect of system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

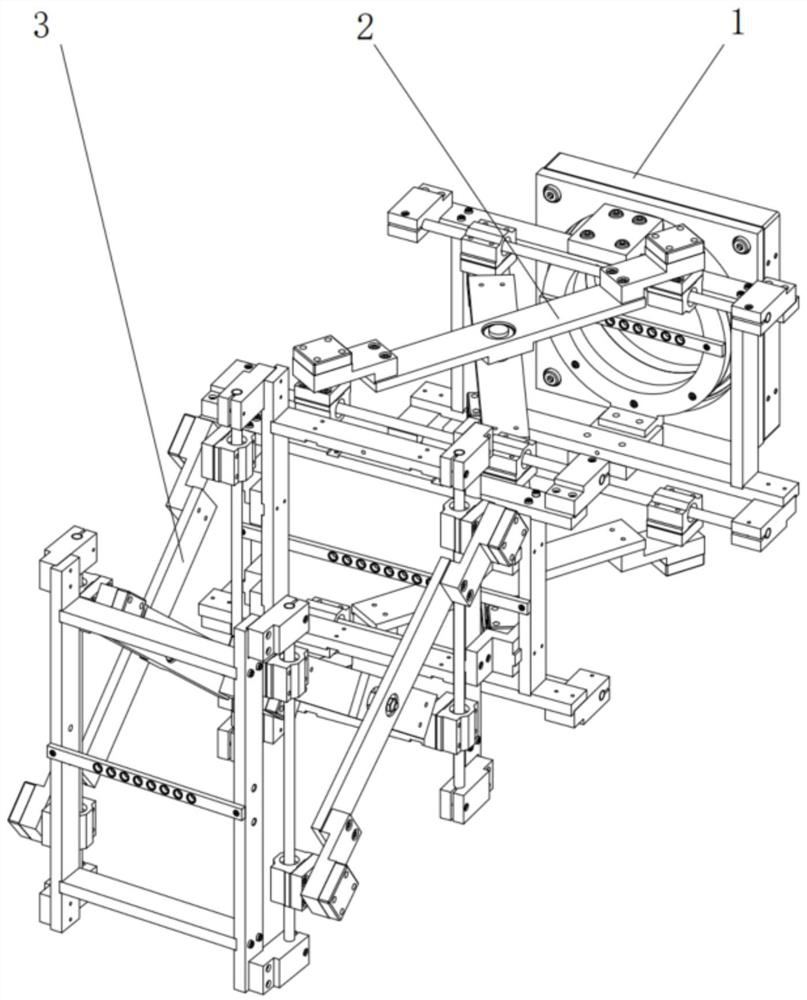

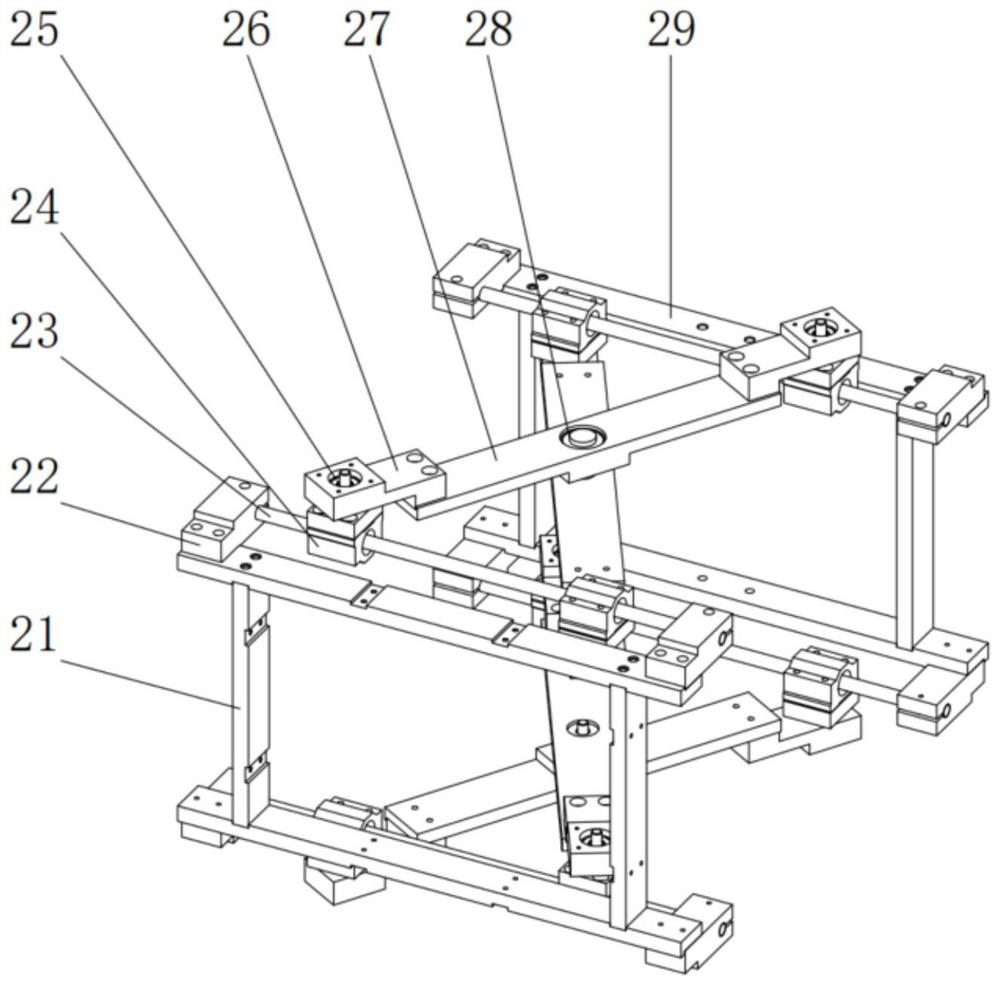

[0014] Embodiment 1: Combining Figure 1-Figure 5 This embodiment is described. A yarn guide device for fiber laying described in this embodiment includes a rotating mechanism 1, a pitching mechanism 2 and a swinging mechanism 3. The fixed end of the rotating mechanism 1 is fixedly connected with the yarn guide frame and rotates The rotating end of the mechanism 1 is connected with the fixed end of the pitching mechanism 2, the moving end of the pitching mechanism 2 is connected with the fixed end of the swinging mechanism 3, the moving end of the swinging mechanism 3 is connected with the yarn guide, and the fiber tow is connected by the rotating mechanism 1 in turn. It is provided through the pitch mechanism 2 and the swing mechanism 3.

specific Embodiment approach 2

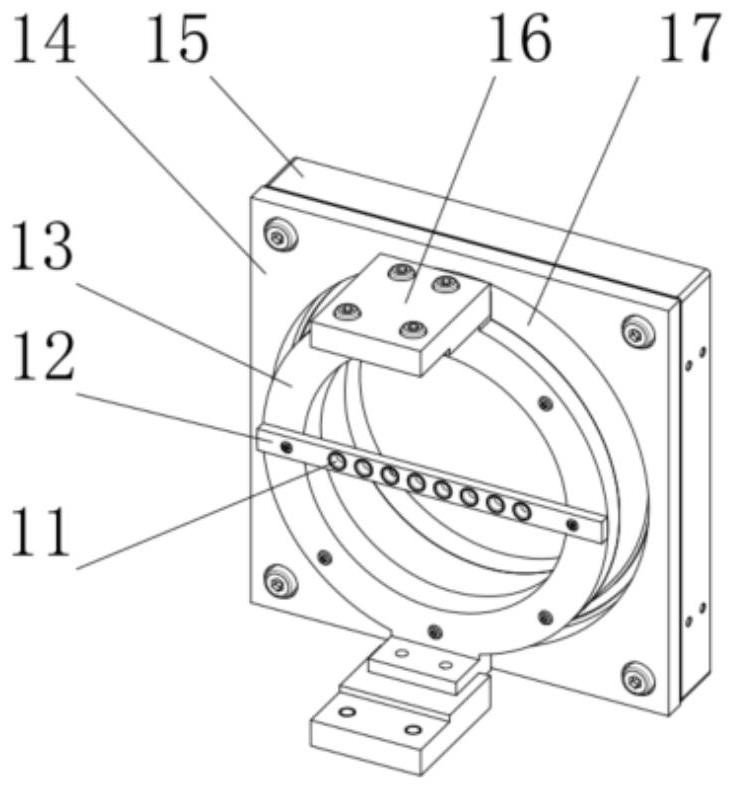

[0015] Specific implementation mode 2: Combining Figure 1-Figure 2 Illustrating this embodiment, a yarn guide device for fiber laying described in this embodiment, the rotating mechanism 1 includes a first ceramic ring support 12, a bearing connecting ring 13, a bearing seat cover 14, a bearing seat 15, a cross Roller bearing 17, two connecting blocks 16 and multiple first yarn guide ceramic rings 11; multiple first yarn guide ceramic rings 11 are mounted on the first ceramic ring support 12, and the first ceramic ring support 12 is fixedly mounted on the bearing On the connecting ring 13, two connecting blocks 16 are symmetrically arranged and fixedly installed on the bearing connecting ring 13, the bearing connecting ring 13 is fixedly installed on the inner ring of the crossed roller bearing 17, and the outer ring of the crossed roller bearing 17 is installed on the bearing. Inside the seat 15 , the bearing seat cover plate 14 is mounted on the bearing seat 15 , and the fi...

specific Embodiment approach 3

[0016] Specific implementation three: combination Figure 1-Figure 2 Describing this embodiment, a yarn guide device for fiber laying described in this embodiment, a plurality of first yarn guide ceramic rings 11 are arranged in a straight line and installed on the first ceramic ring support 12 . A plurality of first yarn-guiding ceramic rings 11 are installed on the first ceramic ring support 12 at a certain interval to control the fiber spacing to avoid entanglement between fibers and excessive friction to damage the fibers. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com