Passive Cooling Device for Differential Transformer Displacement Transducers (lvdt)

A differential transformer type, displacement sensor technology, applied in the direction of using electrical devices, measuring devices, electromagnetic measuring devices, etc., can solve the problems of reduced measurement accuracy and burnout, and achieve reliable cooling, high safety performance, and simple operation and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

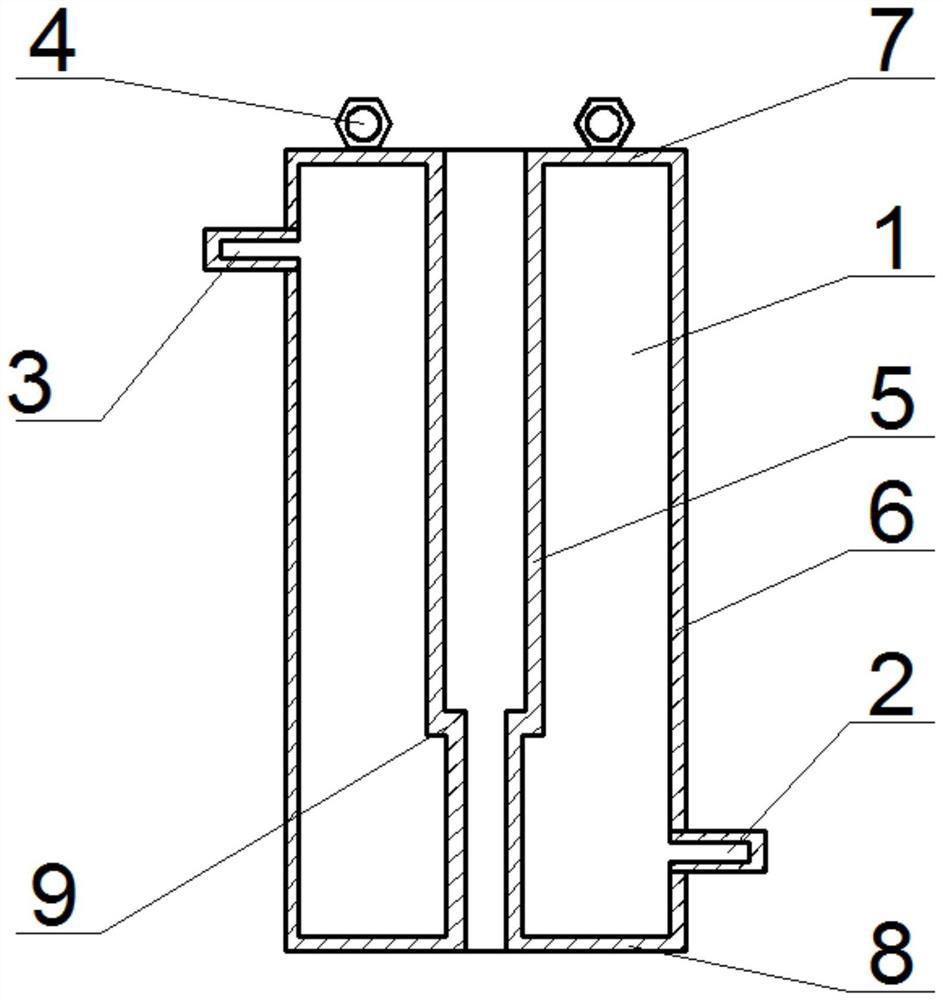

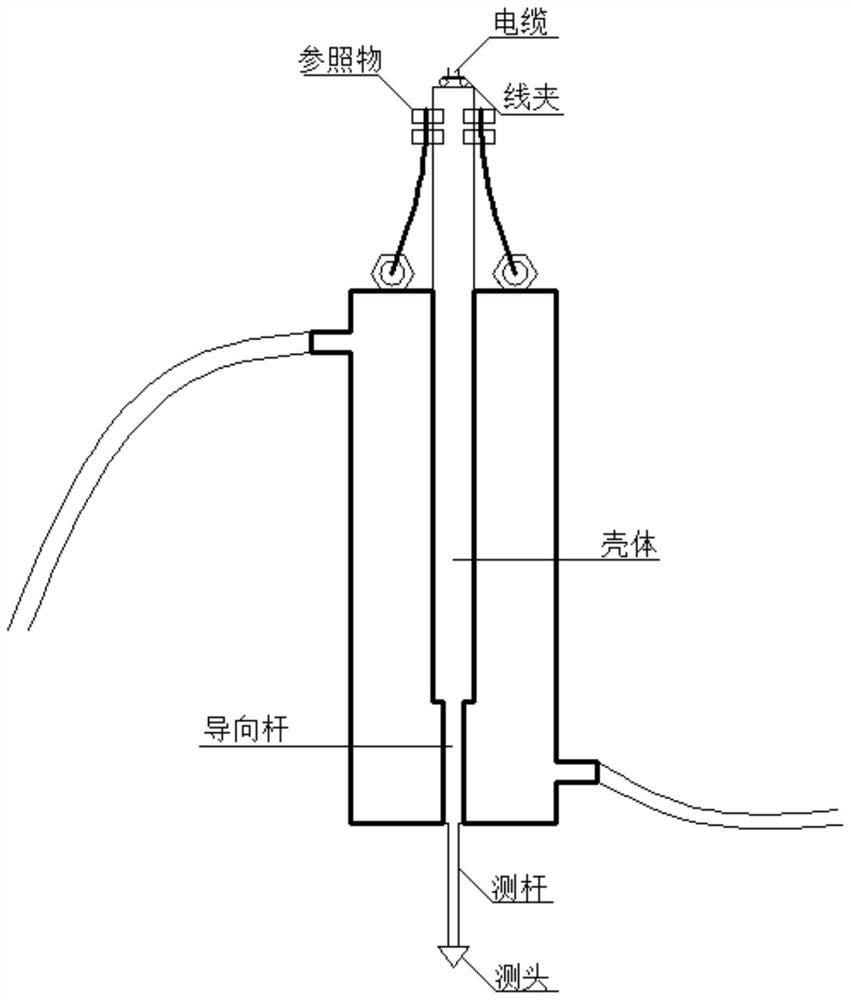

[0015] combined with figure 1 to attach figure 2Illustrate the specific embodiment of the present invention: the passive cooling device used in the differential transformer type displacement sensor (LVDT) of the present invention includes a main body 1, a water inlet pipe 2, a water outlet pipe 3 and a nut 4, and the main body 1 includes an inner wall 5, an outer wall 6, an upper Wall 7 and lower wall 8, the inner wall 5, outer wall 6, upper wall 7 and lower wall 8 constitute the inner cavity of the main body, wherein the upper wall 7 and the lower wall 8 are ring plates, and the inner ring size of the upper wall 7 Greater than the inner ring size of the lower wall 8; the inner wall 5 is composed of two cylindrical shells with different radii, the two cylindrical shells are respectively the first cylindrical shell and the second cylindrical shell, the first cylindrical shell and the second cylindrical shell The cylindrical shells are connected by connecting wall 9, which is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com