Mosquito net elevator

A lifting mechanism and mosquito net technology, applied in the field of lifting mechanism, can solve the problems of slow speed, re-lifting of the mosquito net, loss of braking effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

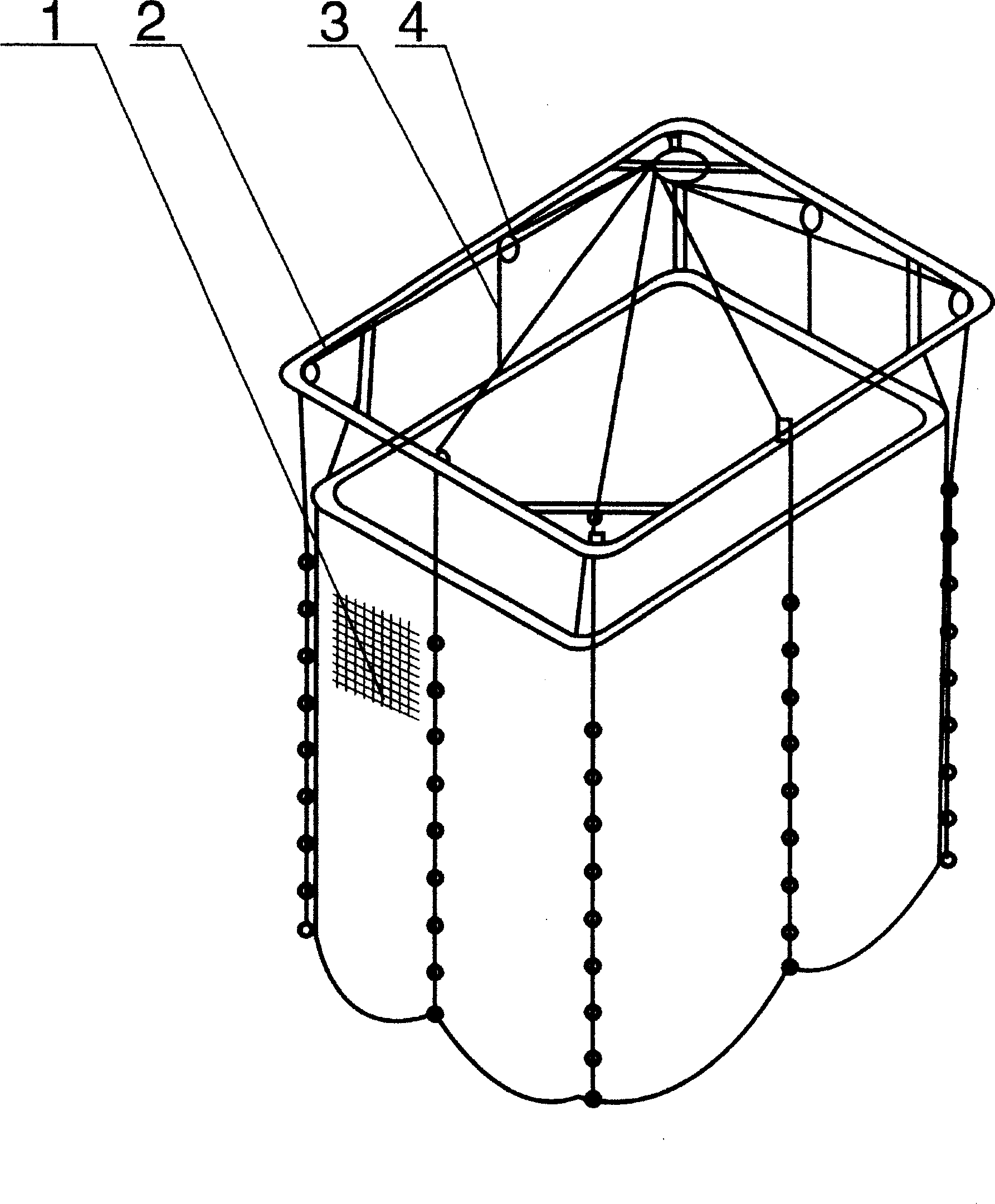

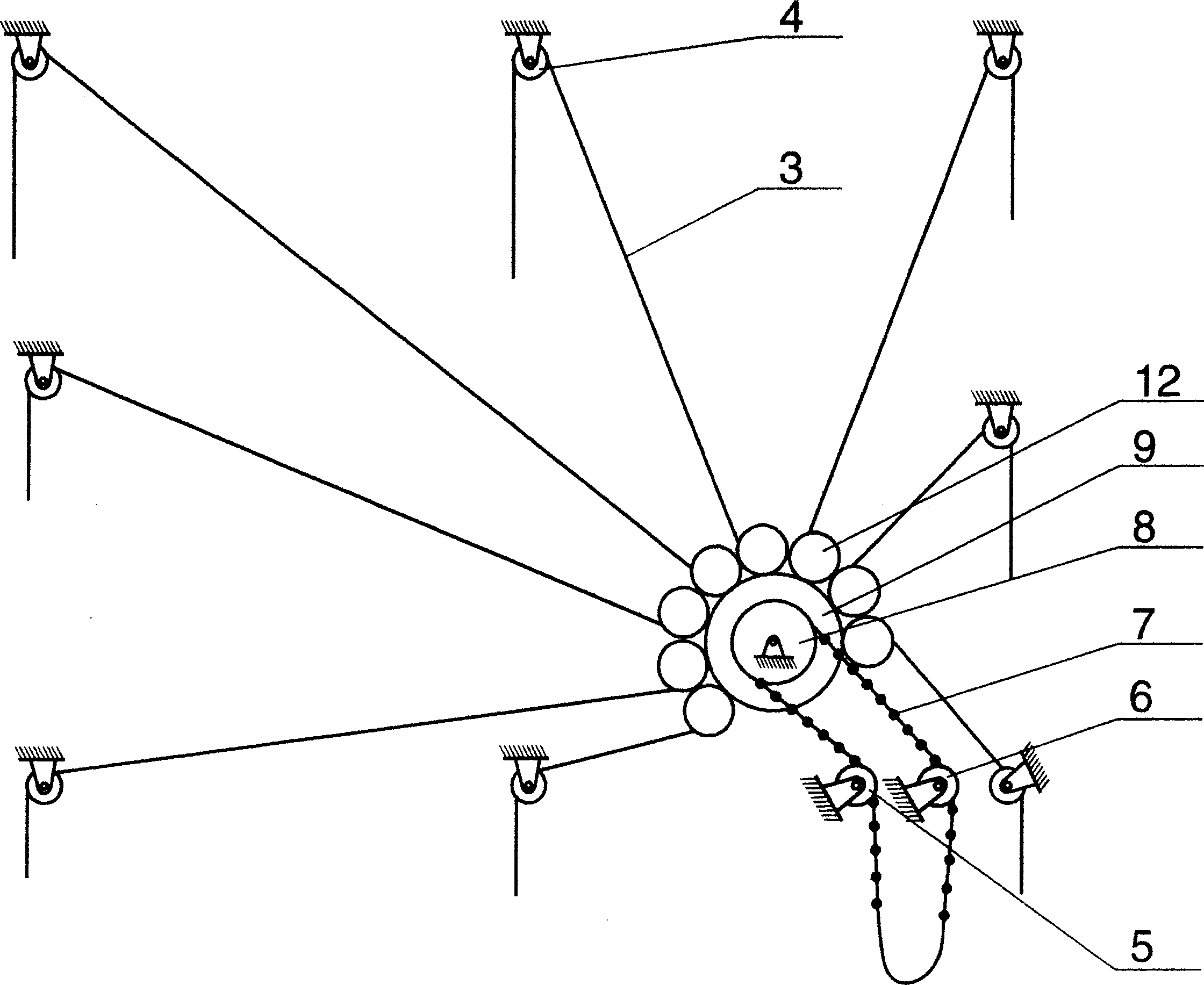

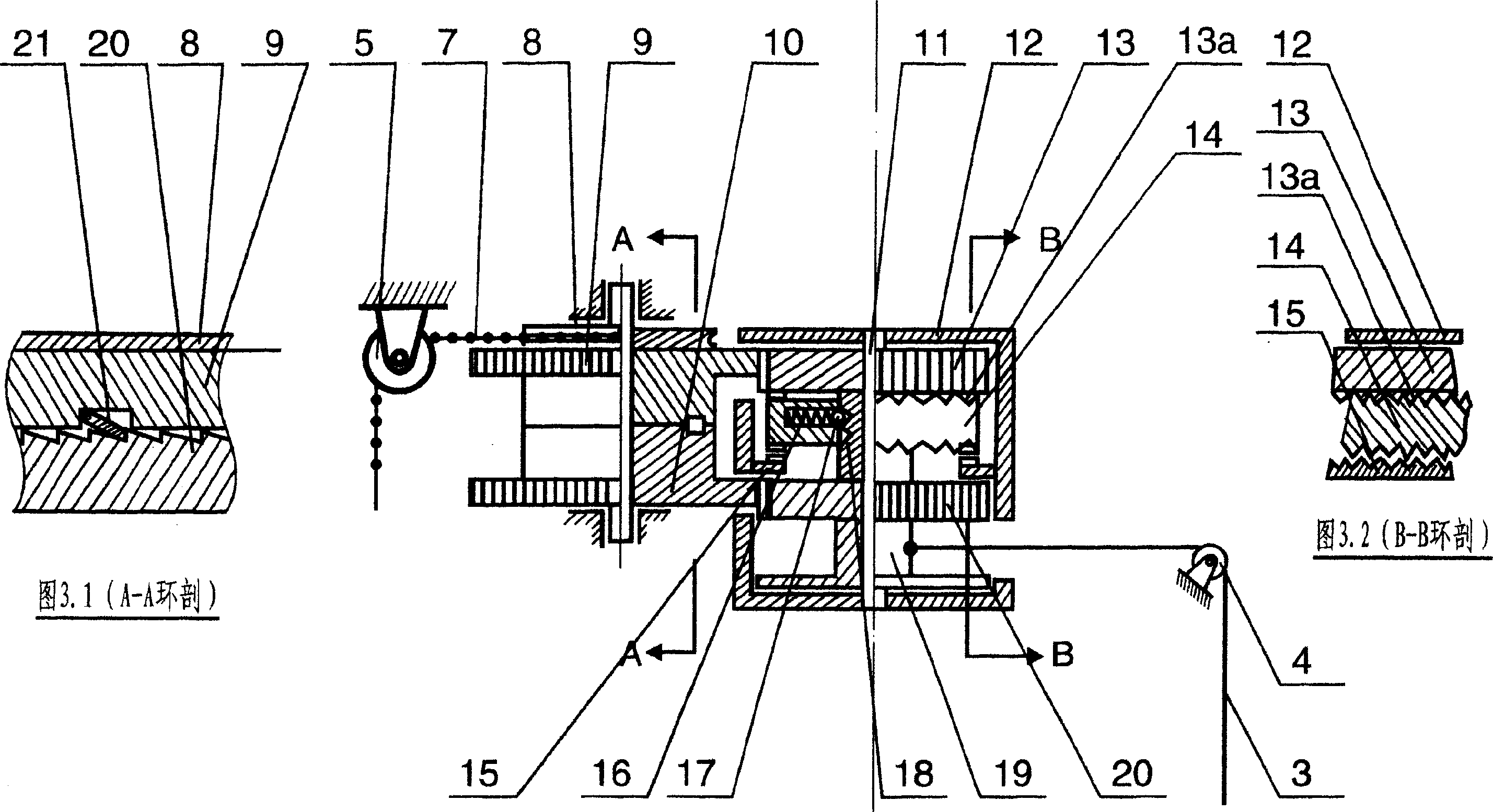

[0030] Such as figure 2 As shown, the drive device of the present embodiment is a human drive device composed of pulley 5, pulley 6, bead chain rope 7 and sprocket wheel 8 matched therewith;

[0031] Such as figure 1 , figure 2 , image 3 , image 3 .1 and image 3 As shown in .2, the driving gear 9 is connected with the sprocket 8, and the driving gear 9 passes through the transmission tooth 21 in the pit of the bottom surface of the counter driving gear 10 and the annular tooth surface positioned on the top surface of the counter driving gear 10. The formed one-way transmission device is connected with the reverse driving gear 10; the periphery of the driving gear 9 and the reverse driving gear 10 is connected with tractors equal to the number of traction points necessary for the tent body 1 (the appearance is that the housing 12 and the hoisting rope 3, image 3 Only the internal structure of a tractor is drawn in the middle), and the lower end of the hoisting rope ...

Embodiment 2

[0037] As shown in Fig. 4, Fig. 4.1, Fig. 4.2 and Fig. 4.3, the driving device of the present embodiment is a motor 32, and the periphery of the driving gear 9 is connected with tractors equal to the number of traction points necessary for the tent body 1 (the appearance is a shell Body 12 and lifting rope 3, only draw the assembly figure of a tractor among the figure), the lower end of the lifting rope 3 of each tractor passes through a lifting pulley 4 and guides down and links with a traction point of tent body 1;

[0038] The overload separation device of this embodiment is composed of an internal gear 22, a central shaft 11, a fixed screw rod 24, a slider 23, a top column 26, a pressure spring 27, a bolt wheel 28, a bolt pin 29, a steel ball 30, and a pressure spring 31;

[0039] The brake device of this embodiment is composed of an inner gear ring 33, a brake gear ring 35, and a brake tooth 34;

[0040] The passive gear 13 is hollow, and the inner circumference is fixedl...

Embodiment 3

[0045] Such as Figure 5 As shown, the drive device of the present embodiment is a human-powered drive device composed of a drag cable 36, a drive wheel 37b, and a drive wheel 37. One end of the drag cable 36 is connected in a groove of the drive wheel 37 and wound into the groove 3 to 5 Meter, the other end is connected in the groove of driving wheel 37b;

[0046] Drive gear 9 is sequentially connected with drive wheel 37b, and drive wheel 37 is then passed through the one-way transmission formed by the drive tooth 21 in the pit of the bottom surface of drive wheel 37b and the annular tooth surface on the top surface of reverse drive gear 10. The device is connected with the reverse driving gear 10;

[0047] The periphery of driving gear 9 and reverse driving gear 10 is connected with tractors equal to the number of traction points necessary for account body 1 (the appearance is housing 12 and hoisting rope 3, Figure 5 Only draw the assembly diagram of wherein a tractor), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com