Device for ensuring stamping symmetry of annular supporting ring U-shaped semi-finished product of illuminating lamp of dental operating chair

The technology of operating chair and semi-finished product is applied in the field of punching symmetry guarantee device for U-shaped semi-finished product of annular support ring of dental operating chair lighting, which can solve the problem of different heights of side uprights, difficulty in pressing into a ring shape, and different height differences. OK, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

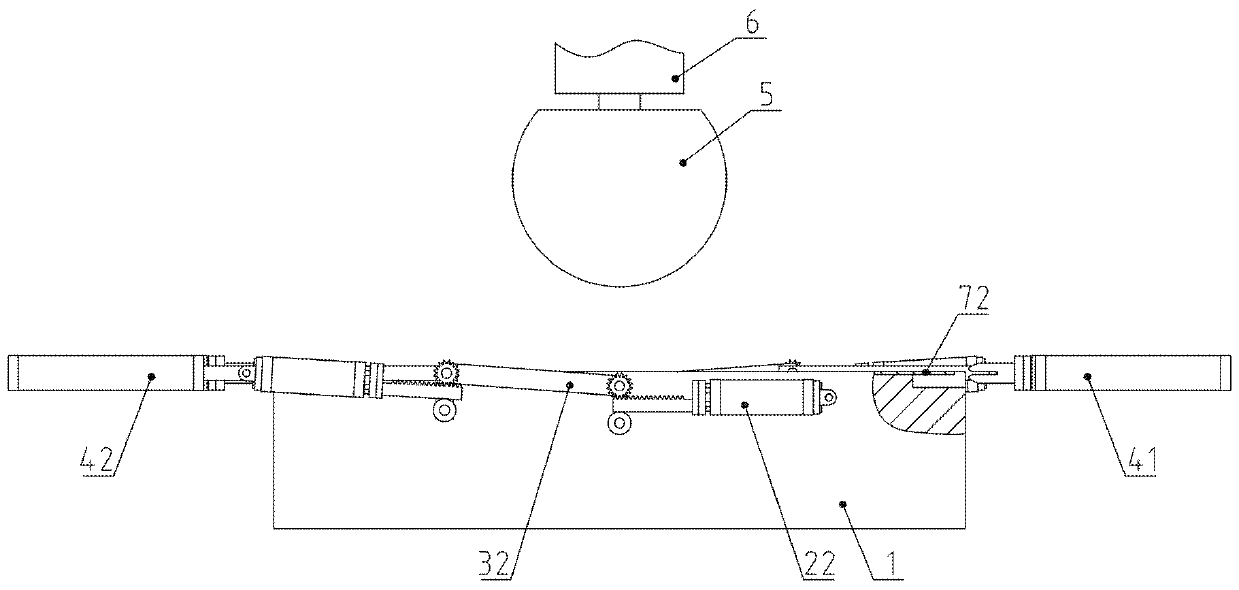

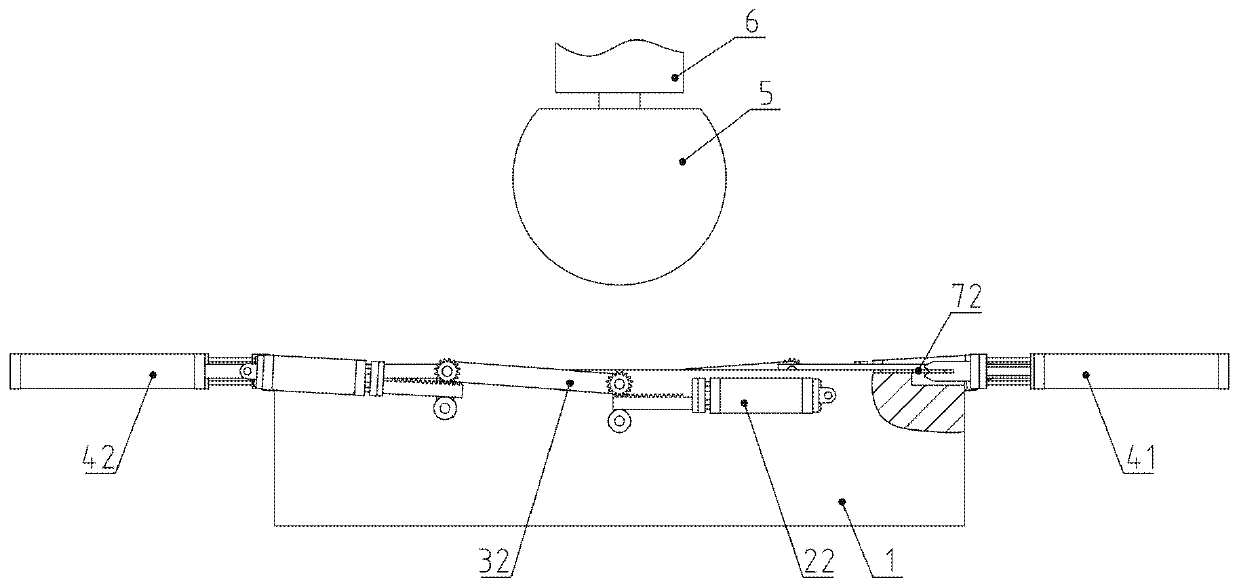

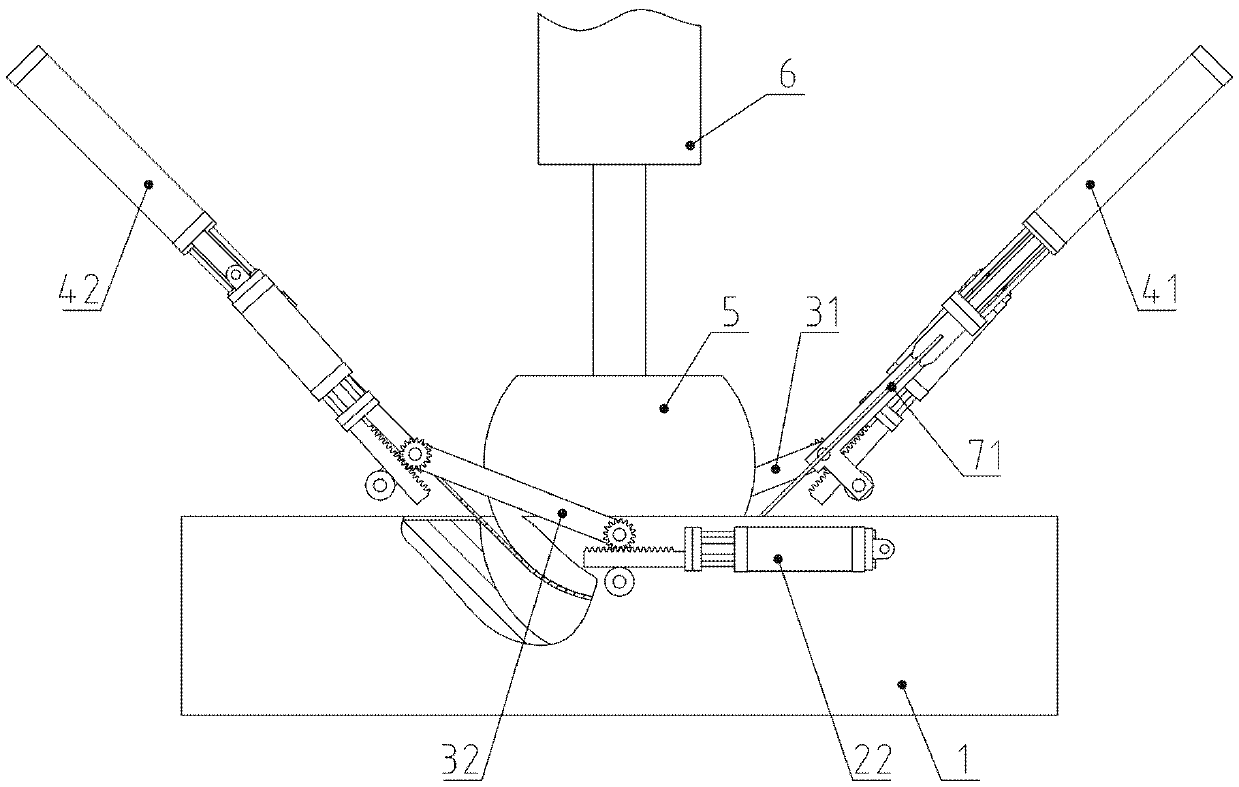

[0069] Example: see Figure 1 to Figure 21 .

[0070] A device for guaranteeing the symmetry of a U-shaped semi-finished product stamping of a dental operating chair illumination lamp ring, including a lower mold assembly 1 and an upper mold 5, the lower mold assembly 1 includes a lower mold base 11, and the lower mold base 11 has an upper positioning groove 111, the depth of upper positioning groove 111 is equal to the thickness of rectangular steel plate 72, and the length and width of upper positioning groove 111 are equal to the length and width of rectangular steel plate 72 respectively, and the middle part of upper positioning groove 111 is provided with semicircle groove 112, semicircle groove 112 The radius equals the outer radius of the semicircular portion at the bottom of the U-shaped semi-finished product, and the upper positioning groove 111 and the semicircular groove 112 are adjacent to the rounded corrugated edge 115; the upper mold 5 is semicircular, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com