Automatic wire harness making system

A production system and automatic line technology, applied in the manufacture of wire harnesses, etc., can solve the problems of one-sided inaccurate evaluation of mechanical connection performance and conduction performance, extended production time of detection steps, waste of time and resources, etc., to avoid waste of resources in subsequent processes, The effect of monitoring and testing is objective, accurate, reliable and high in production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order for those skilled in the art to clearly and completely understand the technical solution of the present invention, the present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

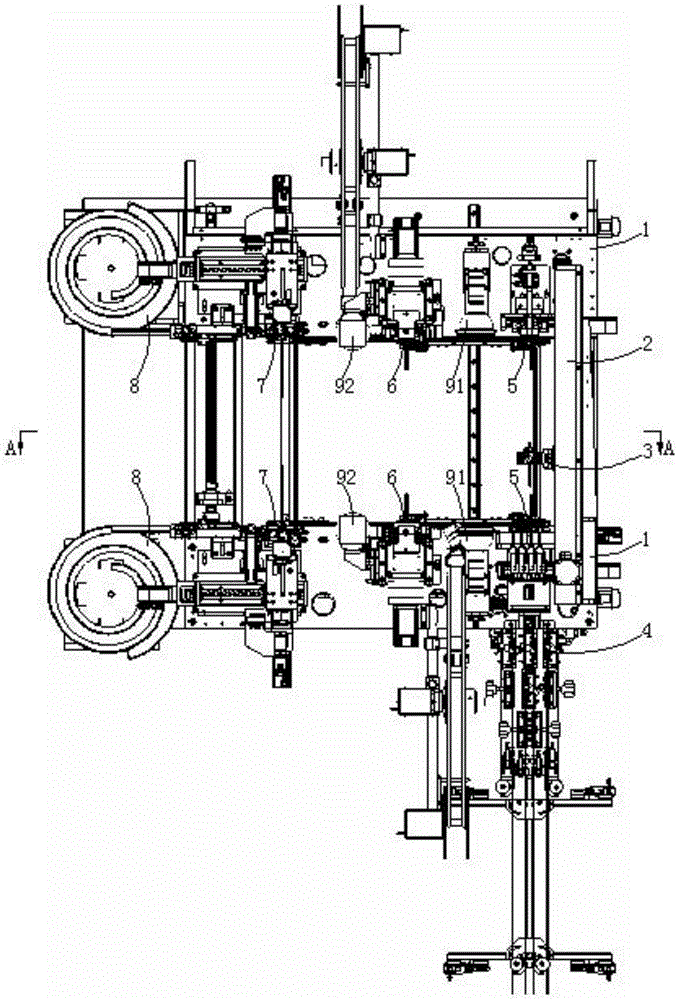

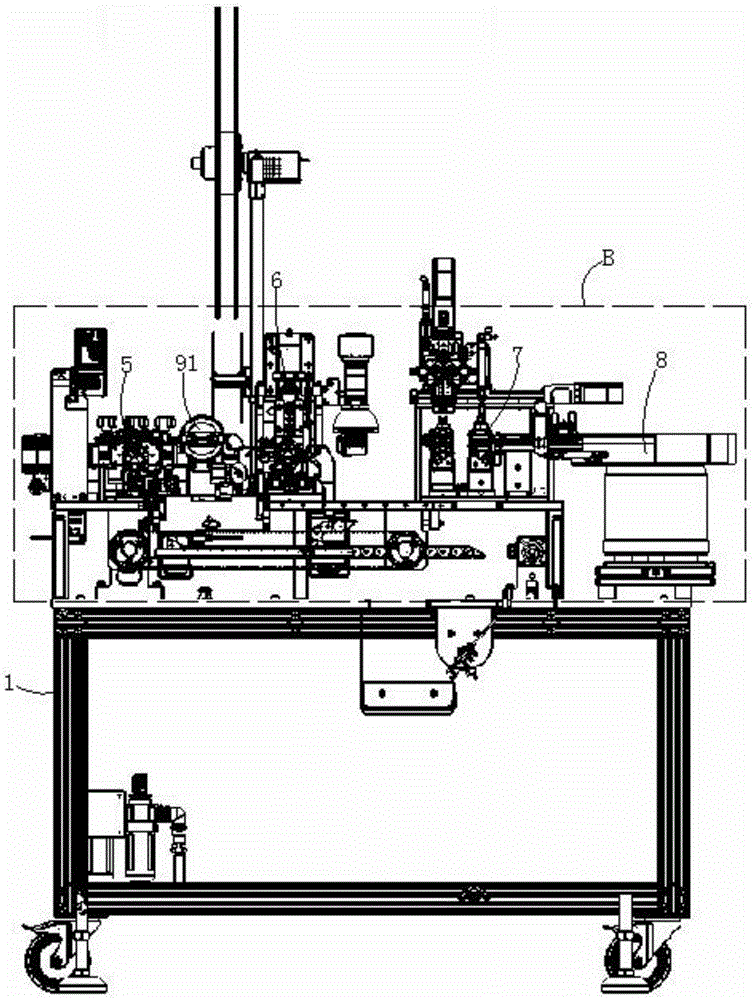

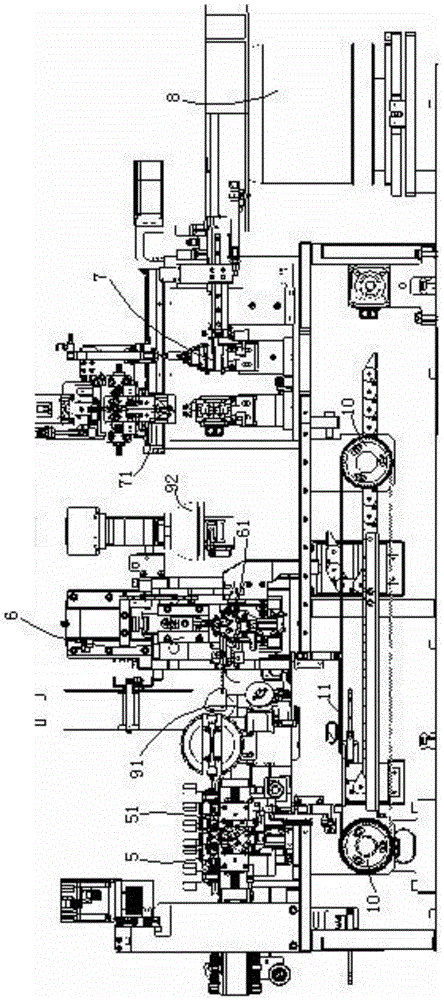

[0037] Such as Figure 1 ~ Figure 3 As shown, the automatic wire harness manufacturing center of this embodiment includes a frame 1, on which are fixedly arranged in sequence from right to left: a pair of stripping and thread cutting mechanisms 5 facing up and down; A video monitoring system 91; a pair of wire terminal mechanisms 6 facing up and down; a pair of second video monitoring systems 92 facing up and down; a pair of plastic shell plug-in mechanisms 7 facing up and down; A pair of rubber shell conveying mechanisms 8 are provided; the wire feeding mechanism 4 that is located below the stripping and cutting wire mechanism 5 on the lower side and feeds the wires thereto. A sliding crossbeam 2 is also fixedly arranged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com