Patents

Literature

35results about How to "Solve the knot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

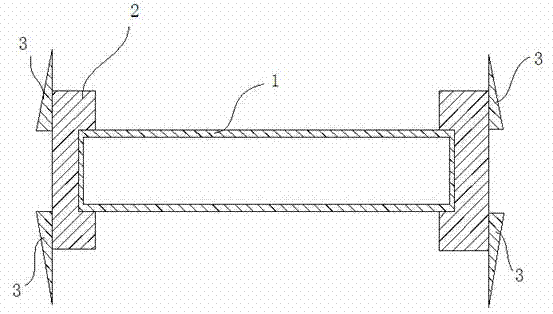

Six-traction device space debris net capture system

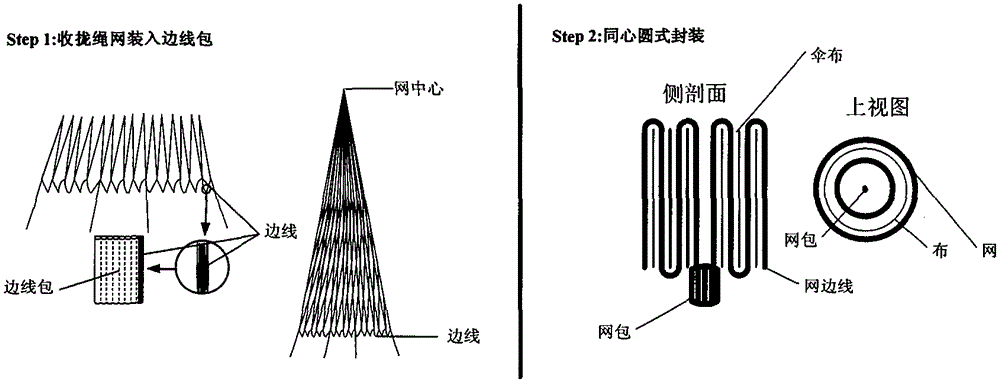

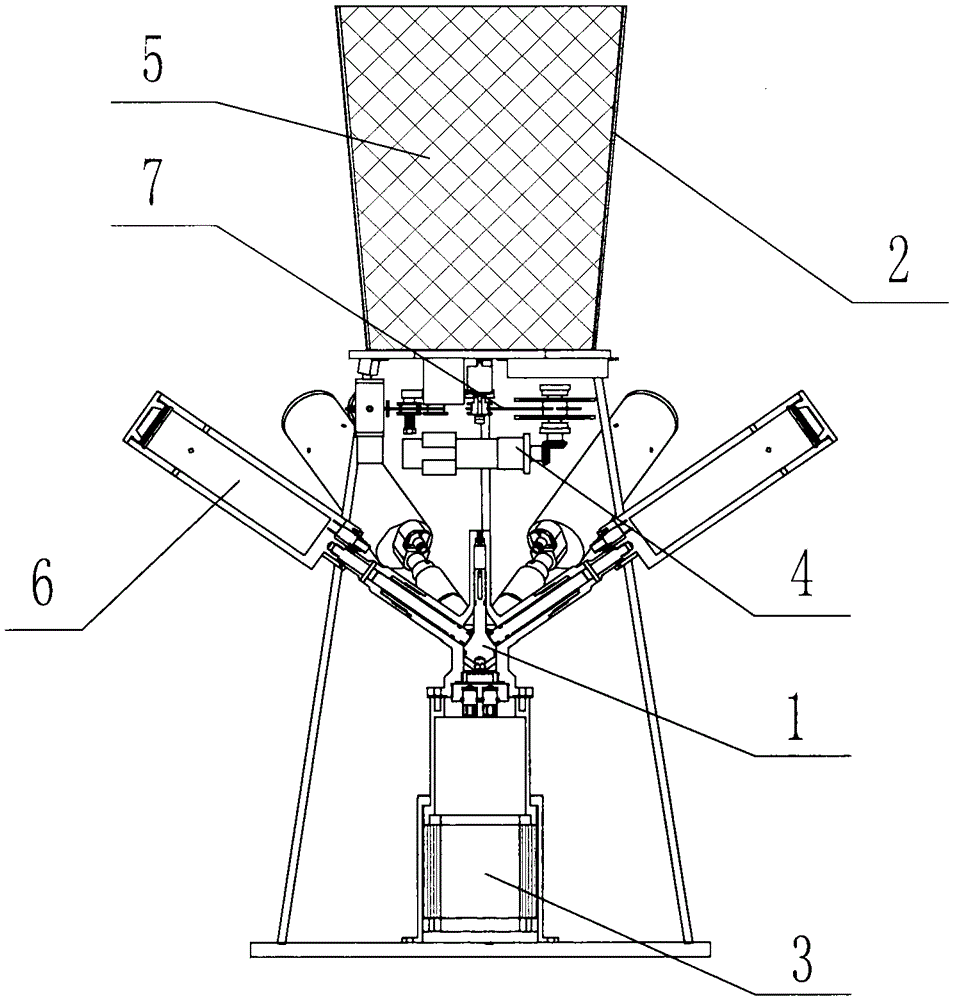

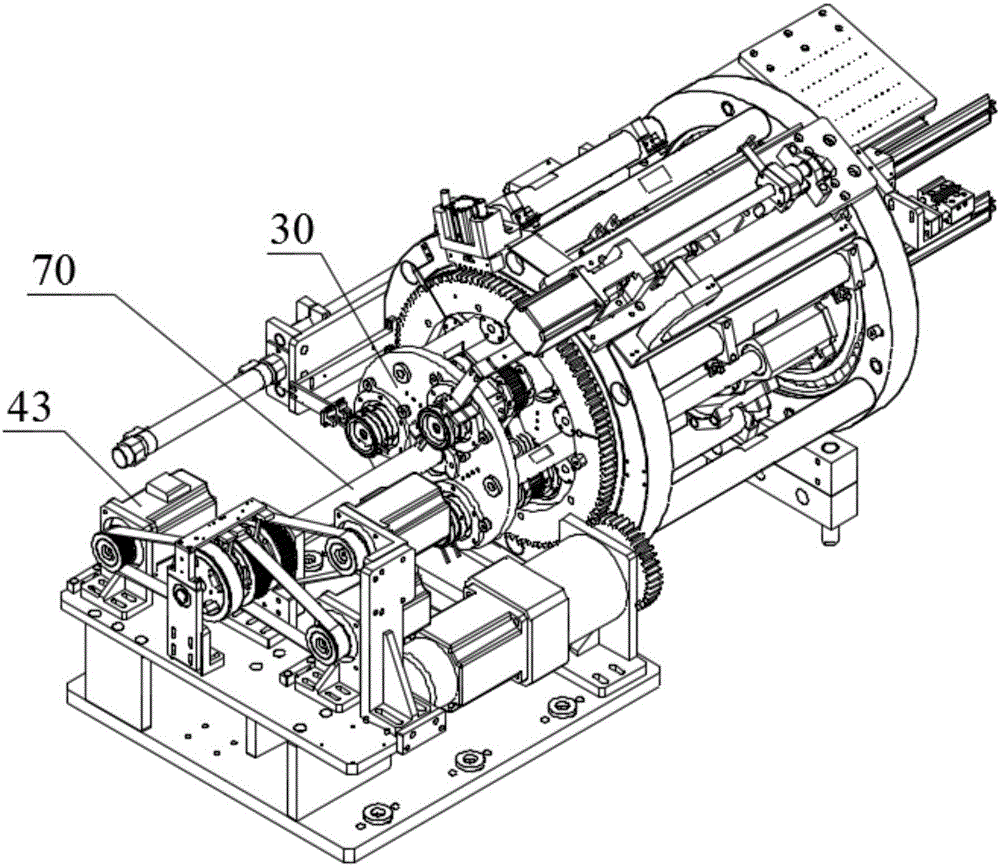

The invention provides a six-traction device space debris net capture system which adopts level-1 launch and mass blocks synchronization launch and concentric circles rope net folding and receiving. The system comprises a launch subsystem which is composed of a launcher, a net hold, a cushioning device and a tether tension control device; a fly net subsystem which is composed of a rope net and mass blocks; the launcher is used for pushing the mass blocks at a predetermined distance from a target at a predetermined angle and to drive the rope net be pulled from the center of the net hold while unfolding to a fully unfolded state to capture the target after reaching the target location; the mass blocks are used for dragging the rope net so that the rope net is pulled out and unfolded and the net opening is tightened up to complete capture of the target; the number of the mass blocks is at least three and six mass blocks are adopted through optimized analysis; the tether tension control device is connected with the fly net subsystem and with the target through the rope net to pull the captured target off the track; the rope net is encapsulated in the net hold in a concentric circles package and is used to form sufficient coverage to completely surround the target.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

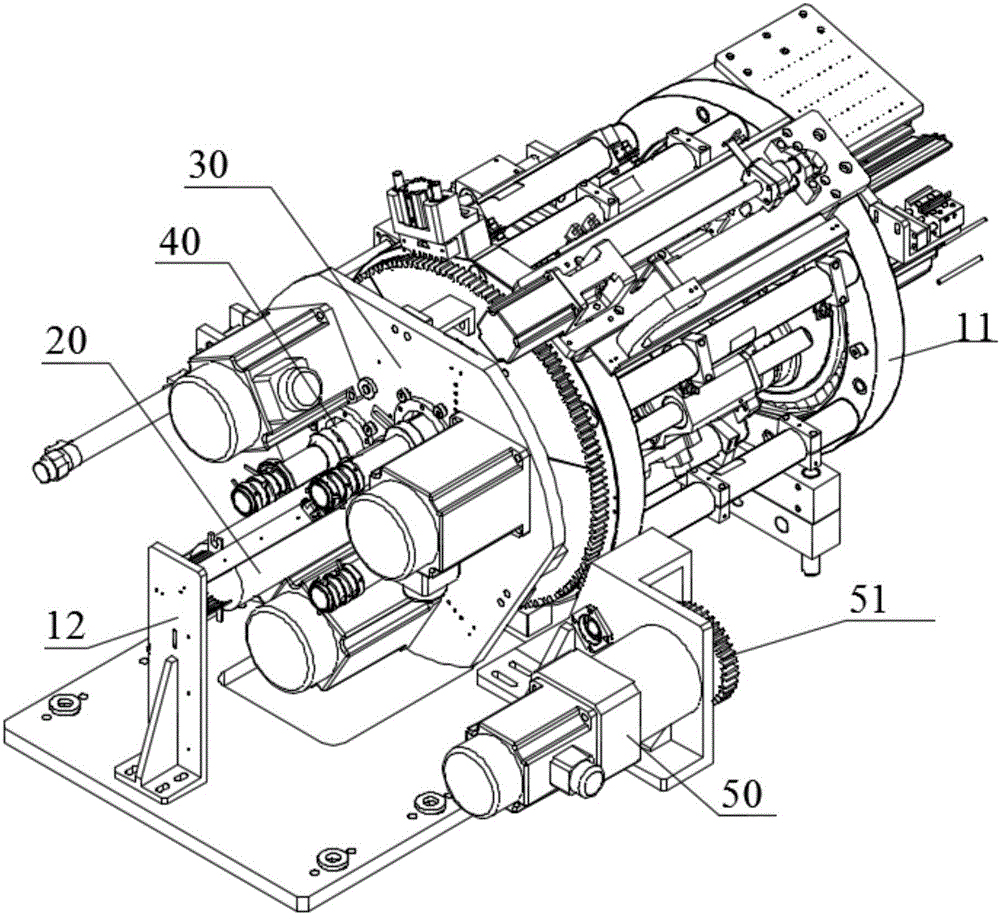

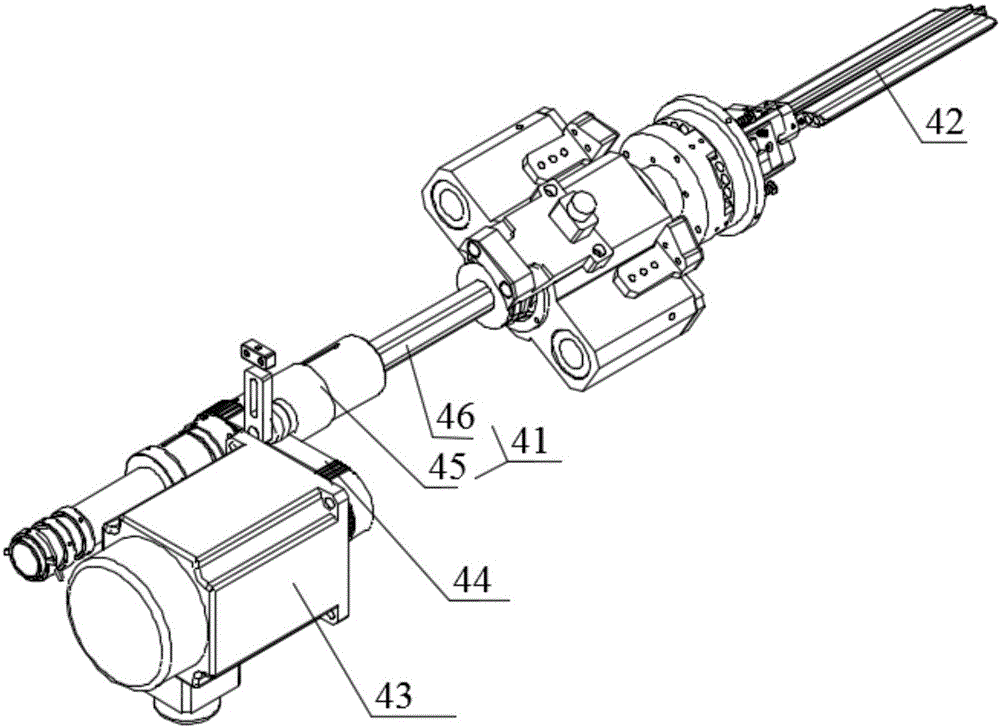

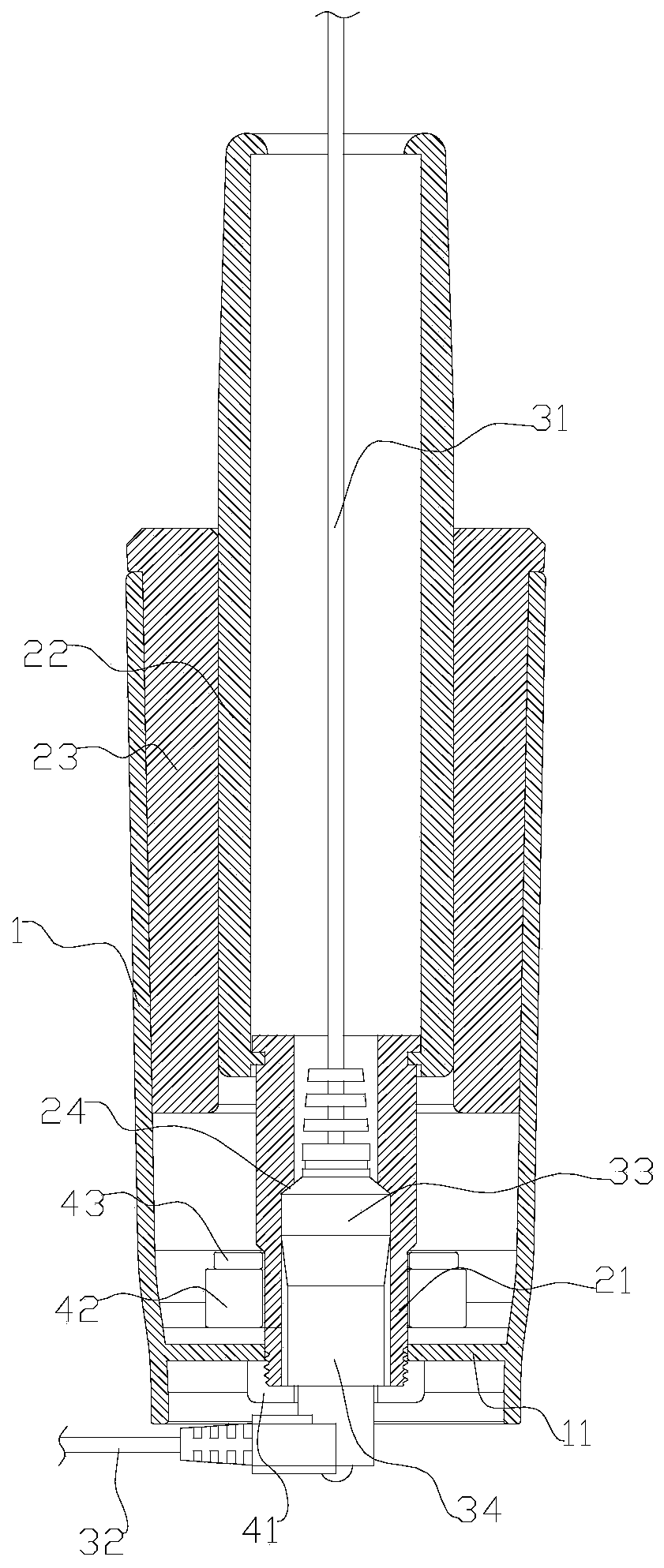

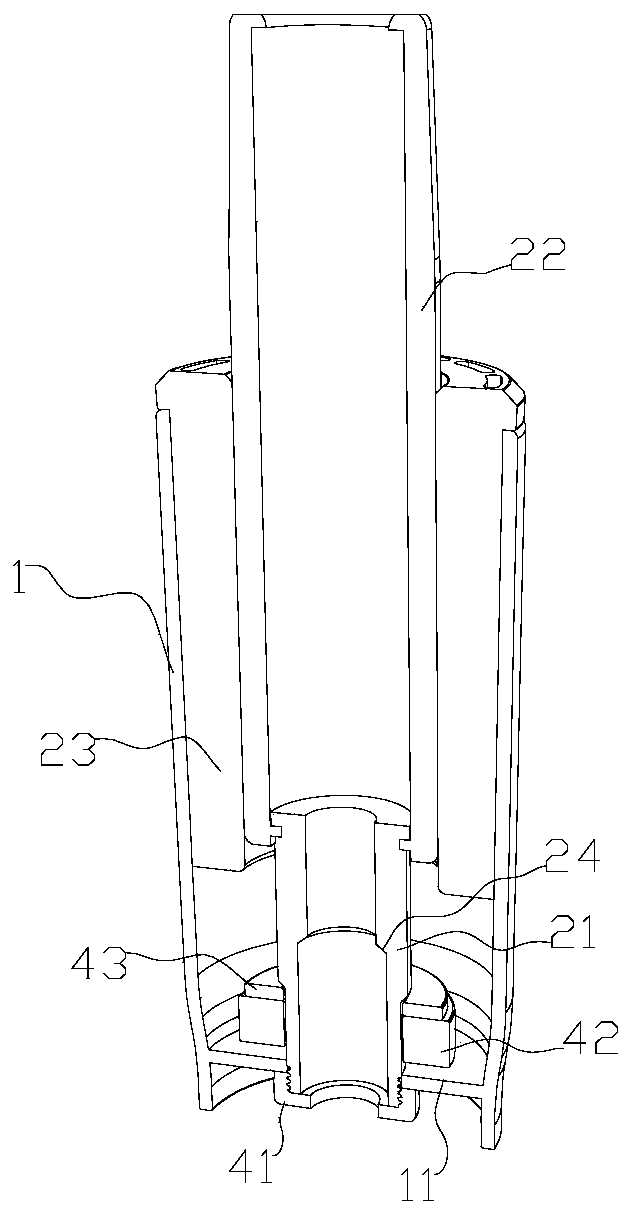

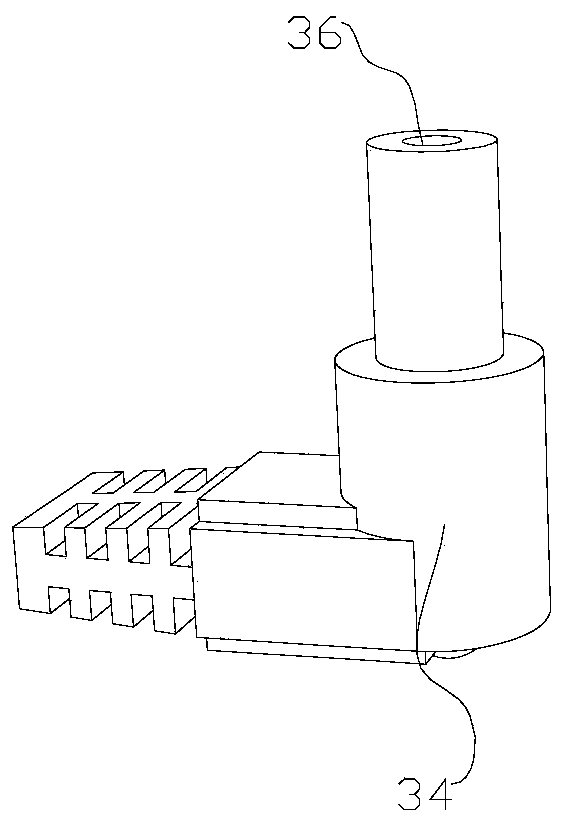

Winding head mechanism

ActiveCN106025326ASolve the knotSmall transmission clearanceAssembling battery machinesFinal product manufactureEngineeringConductor Coil

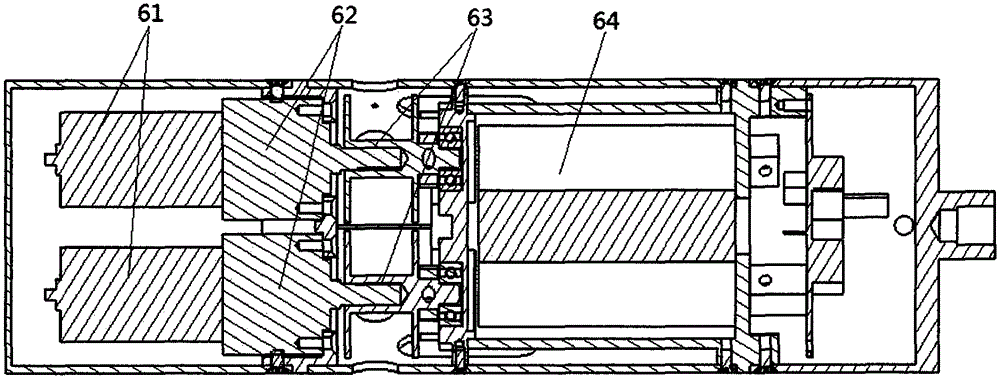

The invention provides a winding head mechanism which comprises a base, a sliding ring, a following plate, a station change motor and at least one winding main body, wherein the sliding ring comprises a rotor and a stator which can rotate relatively; the stator is fixed on a limiting bracket; the following plate is fixedly connected with the rotor of the sliding ring, and can rotate relative to a main supporting part. According to the winding head mechanism provided by the invention, due to the rotatable matching between the rotor and the stator in the sliding ring, the problem that a cable is knotted in the prior art is solved; meanwhile, a winding motor is mounted on the following plate to directly drive a winding driving shaft to rotate and further drive a winding needle to work, so that a transmission gap and an error can be reduced; furthermore, the response speed can be greatly increased, and the winding quality and the efficiency are improved; moreover, speeding up of variable rotating speed control is facilitated, so that the production efficiency is greatly improved, and the equipment cost and the production cost are reduced.

Owner:GEESUN AUTOMATION TECH

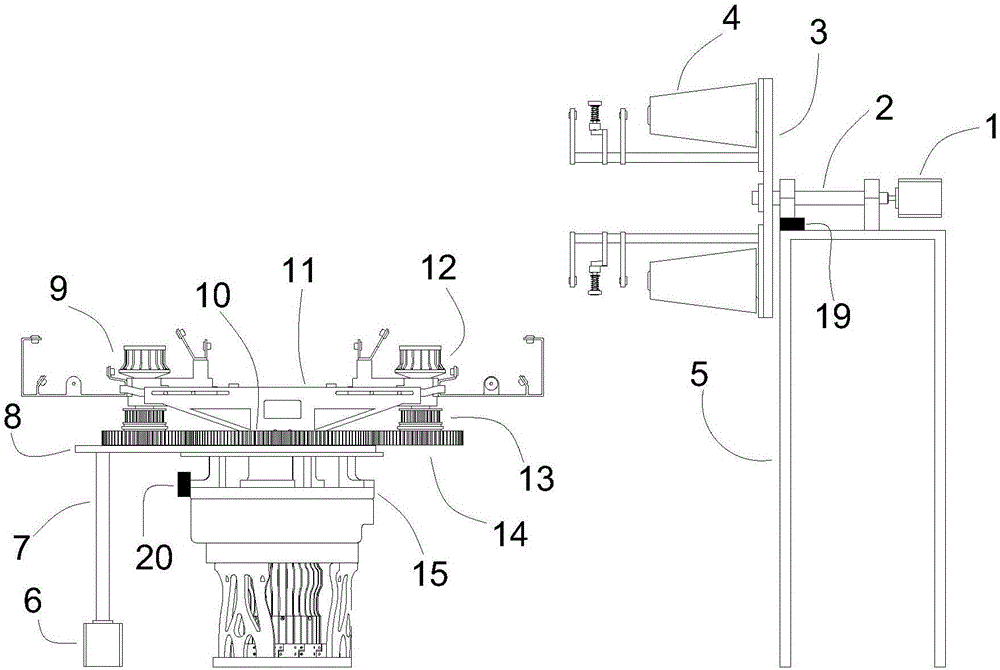

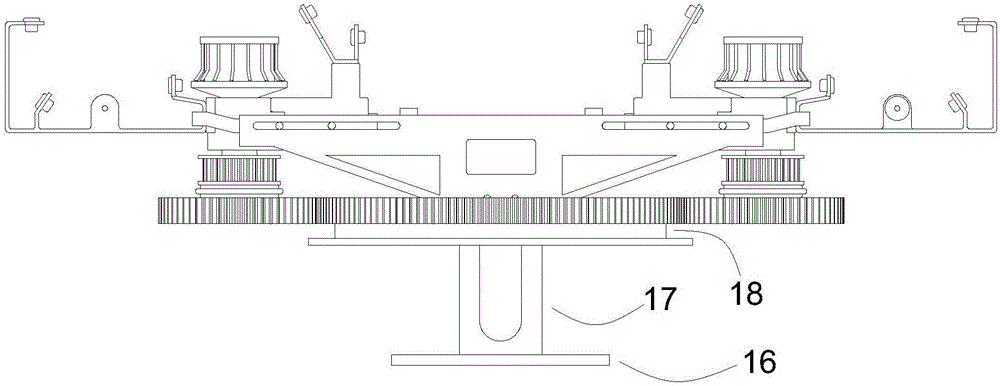

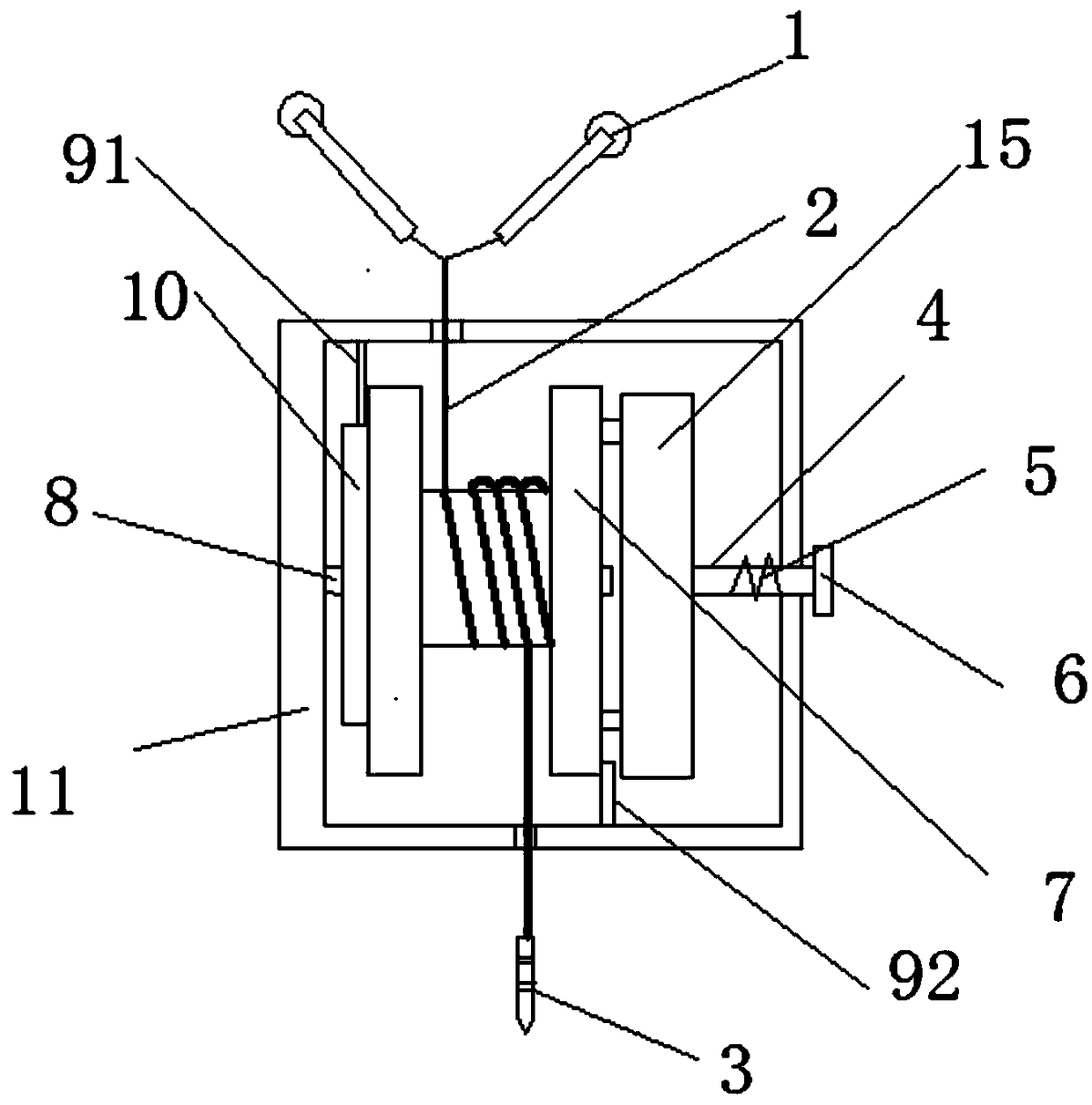

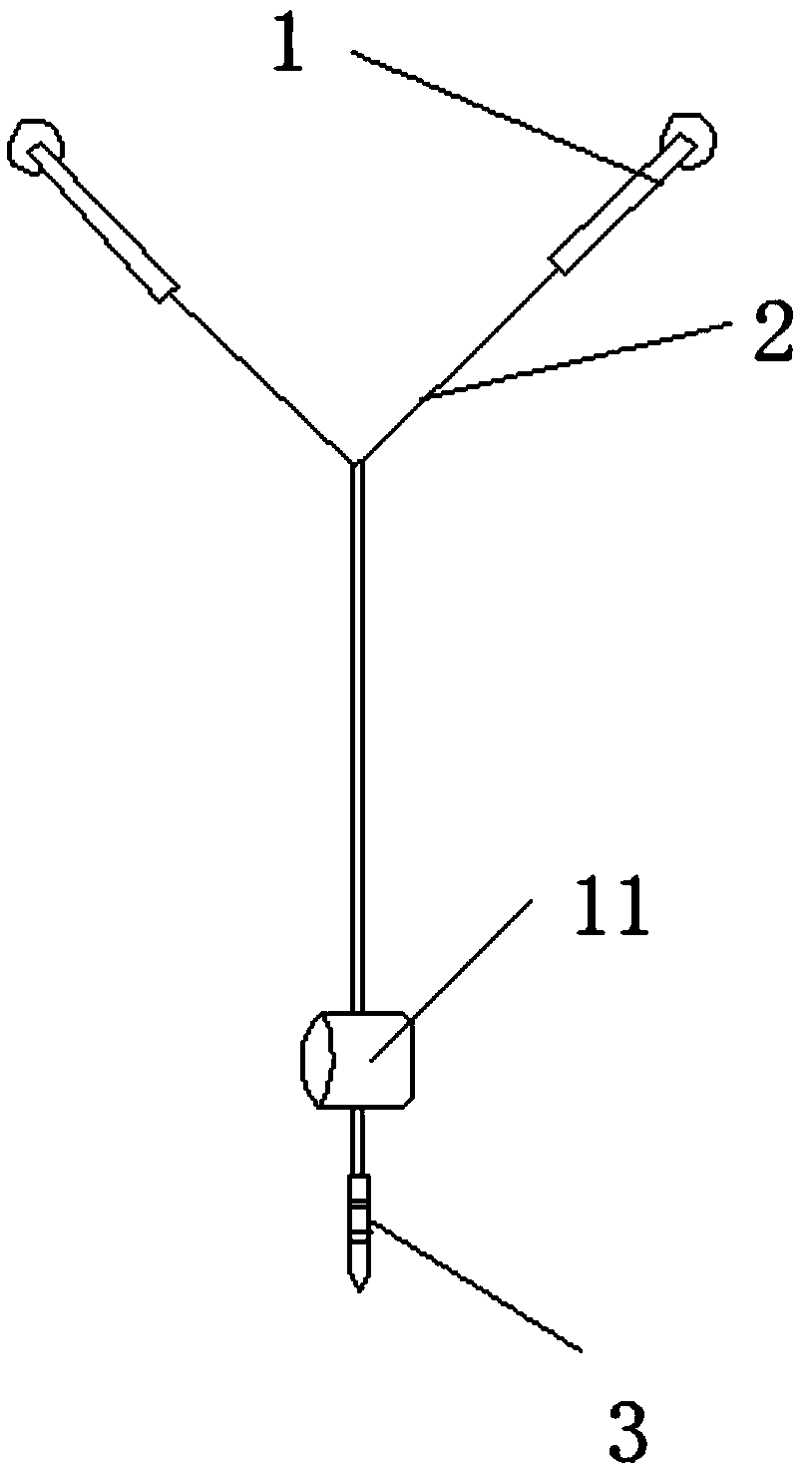

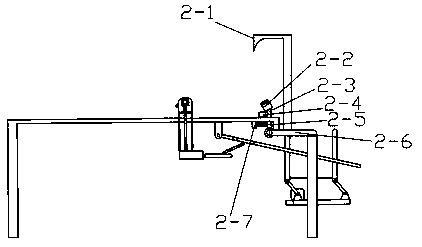

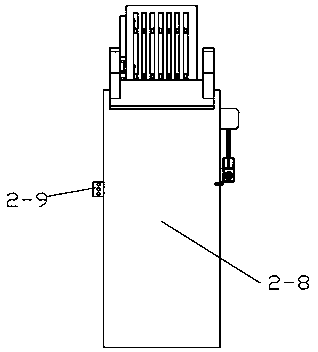

Yarn conveying device and method for electromagnetic driving circular knitting machine

The invention belongs to the technical field of spinning equipment and discloses a yarn conveying method for an electromagnetic driving circular knitting machine. A yarn conveying device comprises a yarn storage drum, a yarn conveyor, a driving mechanism, a detection element and a controller, wherein the yarn storage drum is used for storing the yarns; the yarn conveyor is used for reeling the yarn; the driving mechanism is capable of realizing the stepless regulation of the yarn conveying speed; the detection element is arranged on an end face of the circular knitting machine and a yarn storage drum fixing plate; the controller is used for analyzing a detection signal and regulating the rotating speed of a yarn storage drum motor; according to the yarn conveying method for regulating the yarn conveying speed in real time by utilizing the driving mechanism, the yarn conveying volume and the yarn consumption of the fabric can be balanced; the yarn storage drum and the yarn conveyor are separately arranged and are in the working manner of independently moving, so that the knotting between the yarns moving in a space coordinate can be effectively avoided; the yarn conveyor is indirectly fixed on a cam of the circular knitting machine and an independent driving mechanism is equipped, so that the synchronous rotation of the yarn conveyor and the cam can be guaranteed, the stepless regulation of the yarn conveying speed can be realized, the yarn conveying process is continuous and the yarn-breaking automatic stopping phenomenon can be effectively avoided.

Owner:WUHAN TEXTILE UNIV

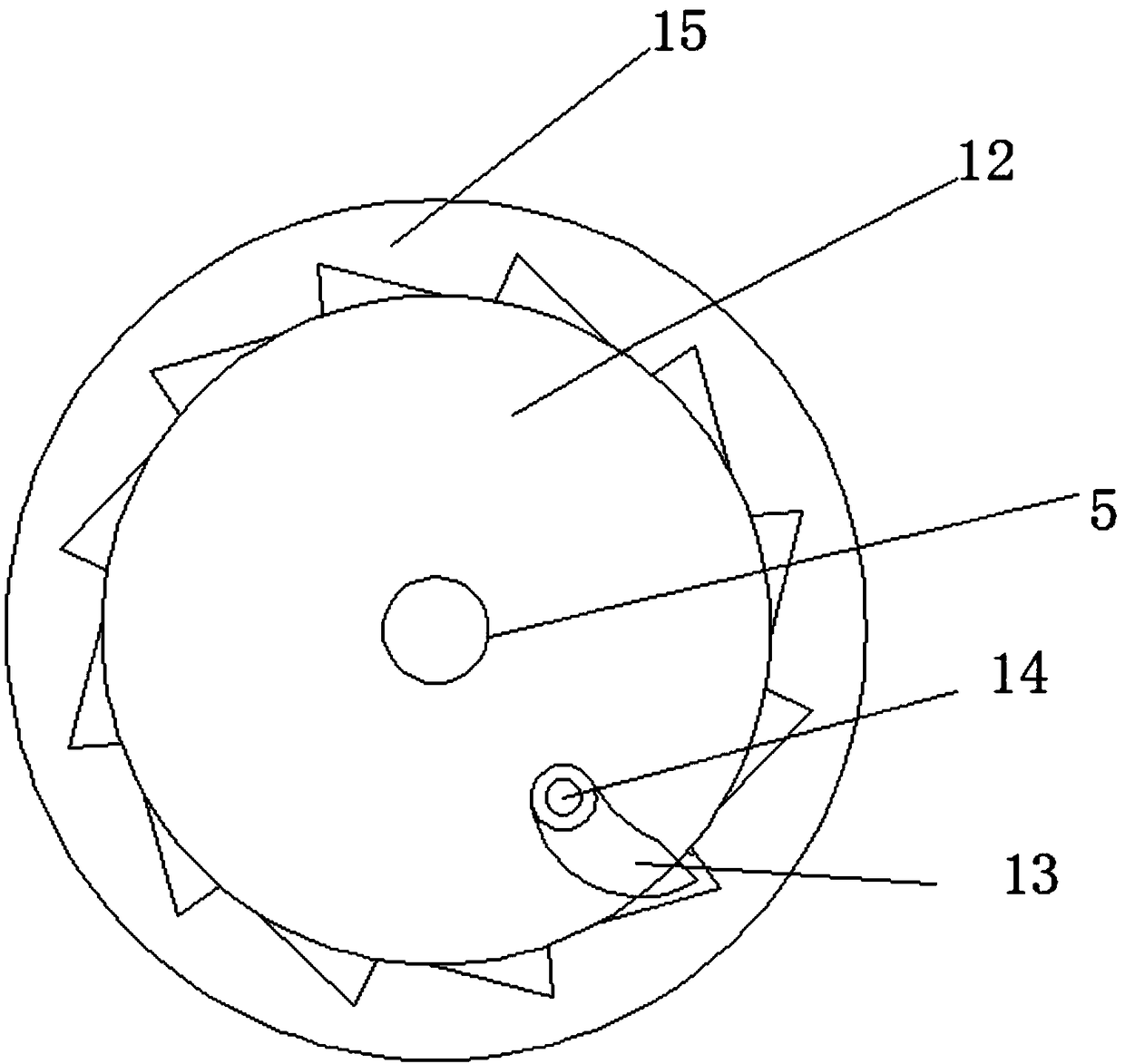

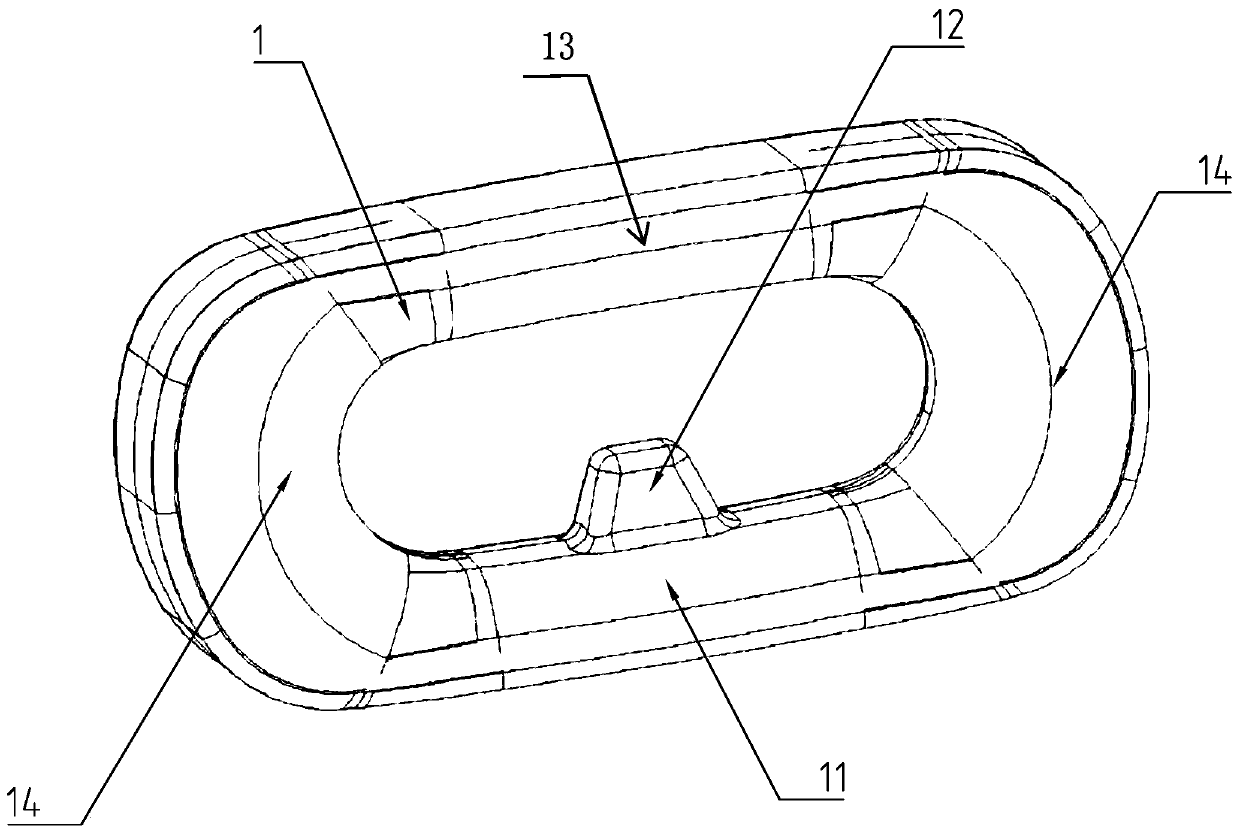

Telescopic earphone

The invention discloses a telescopic earphone, which comprises an earphone main body, a headphone cable, an earphone plug and a telescopic mechanism, wherein the telescopic mechanism comprises an inner ratchet wheel, a pawl, a casing, a rotating shaft and a disc; a turntable is rotatably connected to the rotating shaft; the earphone cable is wound around the middle portion of the turntable; one end of the earphone cable penetrates through the upper portion of the casing and is connected with the earphone main body, and the other end thereof penetrates through the lower portion of the casing and is connected with the earphone plug; a spring is arranged on one side of the turntable; one end of the spring is fixed on the rotating shaft and the other end thereof is fixed on the left end surface of the turntable; the inner ratchet wheel is fixed on the other side of the turntable and is concentric with the turntable; the pawl jams ratchet teeth in the inner ratchet wheel on a cylinder; a pull rod is fixed at the center of the disc; a pressing spring is sleeved on the pull rod; and one end of the pressing spring is fixed at the center of the disc and the other end is fixed on the casing.The telescopic earphone is simple in structure, brings convenience for a user to store the earphone, and solves the problem of knotting and winding due to too long earphone cable.

Owner:CHAOHU UNIV

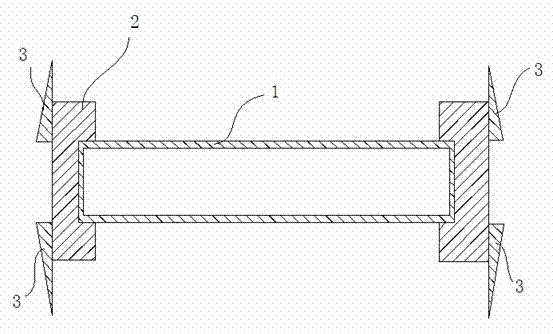

bobbin for textile

The invention provides a bobbin tube for textile, which comprises a tube body and two annular tube covers, and the circular tube covers are fixed at both ends of the tube body, and also includes a plurality of soft plastic strips, the soft plastic strips The plastic strip is fixed on the circular tube cover; the circular tube cover is made of phenolic plastic material, and the tube body is hollow and made of aluminum alloy. The invention solves the problem that the spinning thread on the bobbin is easily knotted and the energy consumption is high during the textile production process. By installing a soft plastic strip on the tube cover, it solves the problem of knotting in the weaving process of the textile machine. The problem of improving work efficiency and product quality; at the same time, by using plastic material for the tube cover, the overall quality of the bobbin is reduced and energy consumption is reduced.

Owner:WUJIANG LONGTAI SPRAY WEAVING FACTORY

Rotating shaft with built-in power line and rotary chair with same

The invention relates to the field of seats, in particular to a rotating shaft with a built-in power line. The rotating shaft comprises an outer pipe and a shaft core assembly, wherein the shaft coreassembly is arranged inside the outer pipe and can rotate relative to the outer pipe; one end part of the shaft core assembly stretches out of the outer pipe for connecting a rotating member; a powerline assembly is arranged inside the shaft core assembly in a penetrating mode; the power line assembly comprises a first wiring section partially arranged inside the shaft core assembly in the penetrating mode and a second wiring section capable of being in butt joint with the first wiring section for electrification; a first wiring terminal at the end part of the first wiring section is embeddedin the shaft core assembly and synchronously rotates with the shaft core assembly, and after the first wiring terminal at the end part of the first wiring section is butted with the second wiring terminal at the upper end part of the second wiring section, the butted part of the first wiring terminal can rotate along the circumferential direction of a shaft core wire of the shaft core assembly. Through the scheme, the problem that knots are generated in the rotating process of internal circuit wiring is solved; the problem of circuit wiring of two parts rotating relative to each other throughthe rotating shaft is overcome, and a group of power supplies can be shared to supply power on the two parts.

Owner:DAKANG HLDG GROUP

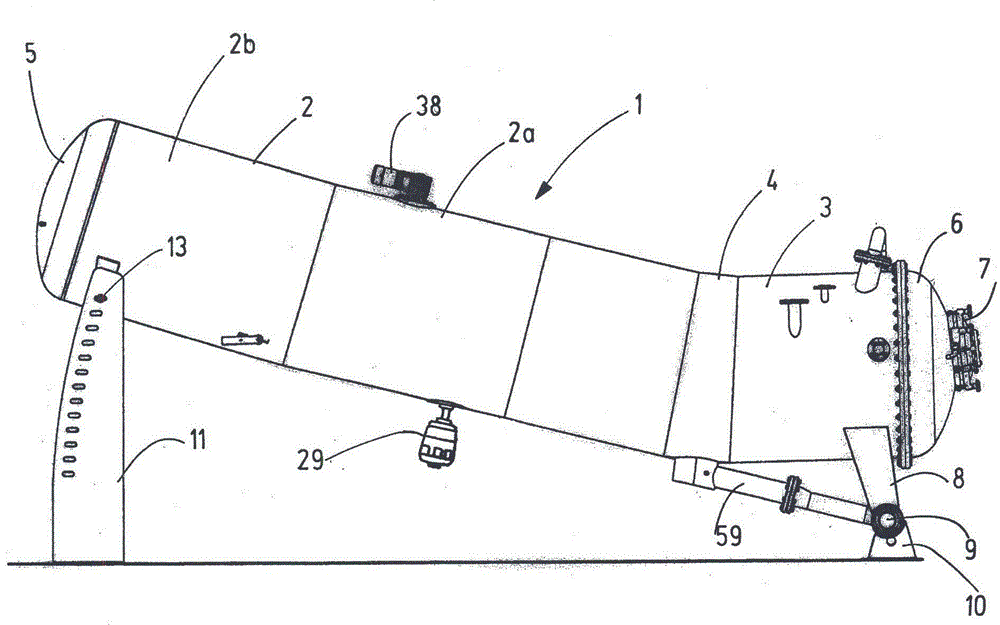

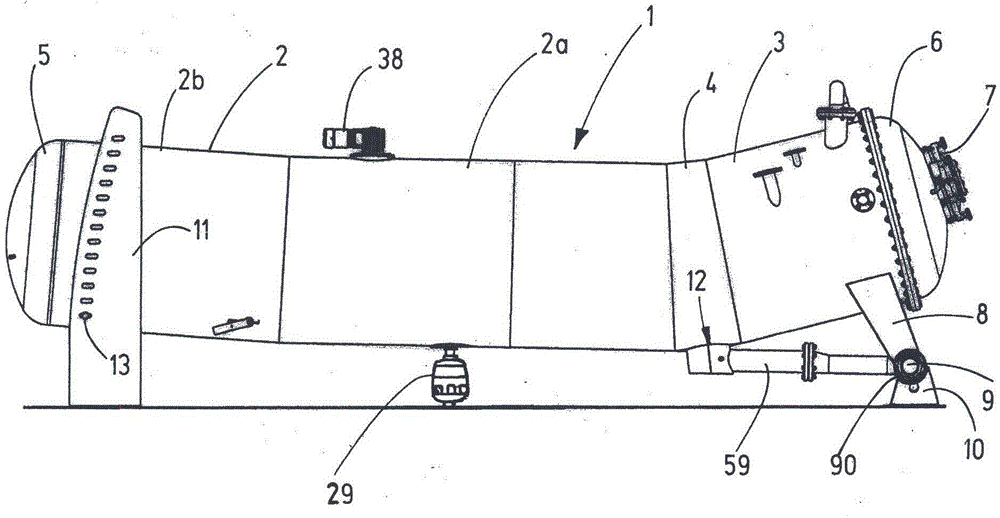

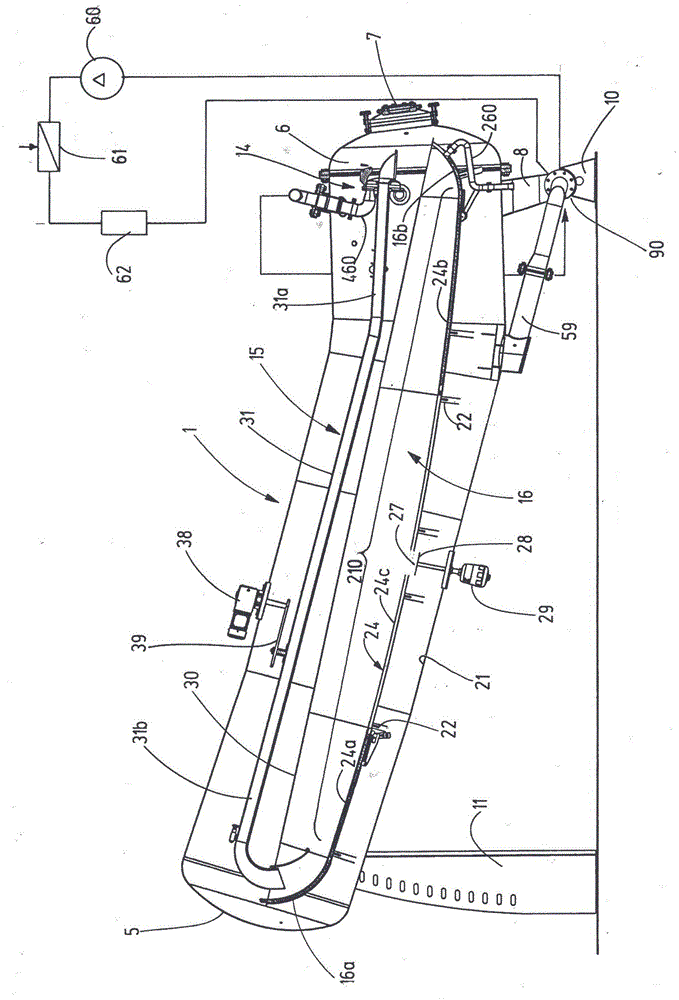

Rope-shaped textile treating system

ActiveCN104018303ASolve the knotSolve problems such as entanglementTextile storage in superimposed formTextile treatment containersArchitectural engineeringTextile

The invention relates to a rope-shaped textile treating system. The system comprises a treating container, a transport nozzle device, a transport portion and a sliding layer, the transport nozzle device, the transport portion and the sliding layer are disposed in the treating container, the transport nozzle device is connected with the transport portion, the sliding layer is disposed below the transport portion, the bottom of the treating container is provided with a treating fluid outlet connected with a water pump through a pipe section, and the water pump is connected to the transport nozzle device through a treating fluid connecting pipe. During a process of using the rope-shaped textile treating system, fabric is automatically cycled under dynamic action of treating fluid, so that the problems of knotting and winding of the fabric are solved. Multiple discharge methods of the treating fluid can be selected, so that the rope-shaped textile treating system can be used conveniently, and an angle of inclination of the treating container is freely adjustable to achieve multiple treating methods.

Owner:FONGS EURO

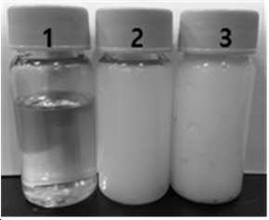

Liquid hair mask and preparation method thereof

PendingCN113230181ASolve hair tangle problemSmooth hairCosmetic preparationsHair cosmeticsProtein proteinGlycerol

The invention relates to the technical field of hair care and hairdressing, in particular to a liquid hair mask and a preparation method thereof. The hair mask disclosed by the invention is liquid and becomes paste when meeting water, the concentration is improved, and the hair can be soft and elastic after the hair mask is applied to scalp and dry hair in only 8 seconds. The liquid hair mask is prepared from the following raw materials in parts by weight: propylene glycol, ethanol, myristyl alcohol, water, cyclopentasiloxane, stearyl trimethyl ammonium chloride, cetrimonium chloride, an anti-hair loss component, behentrimethyl ammonium chloride, isopropanol, sodium lactate, daily essence, butanediol, protein decomposed by adding water, gelatin, mixed amino acid, a plant essence extract, glycerol, and phenoxyethanol by adopting a certain method.

Owner:杨群锁

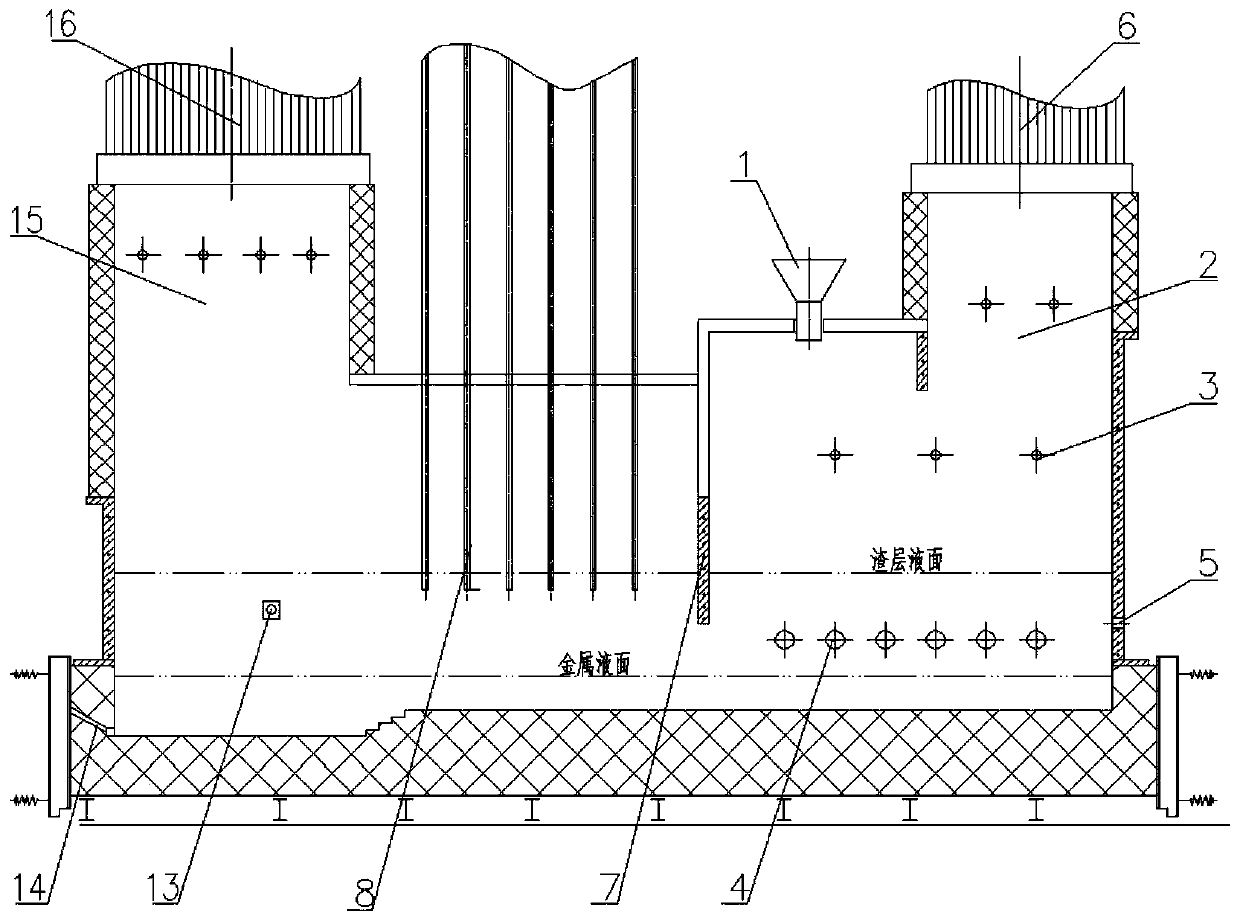

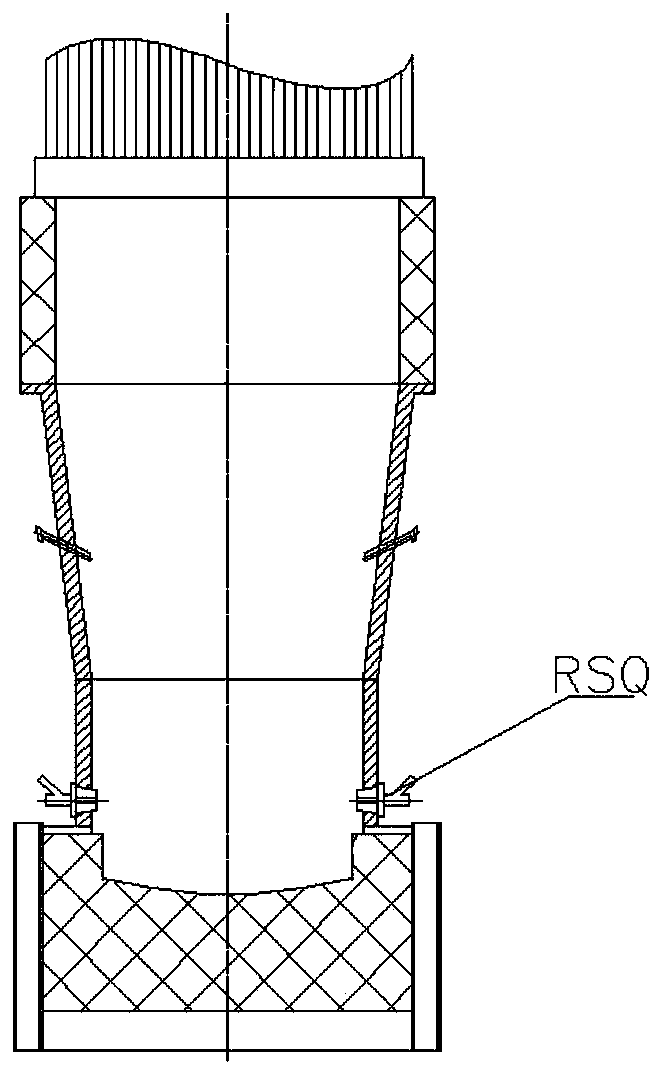

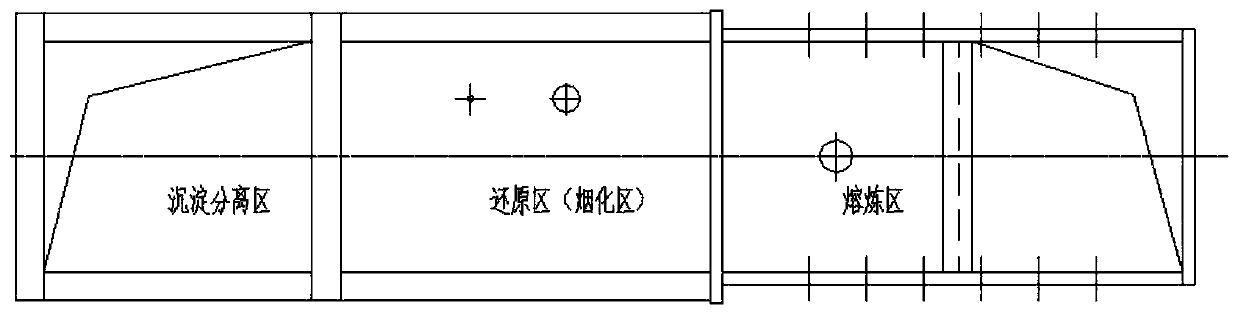

High-efficiency treatment method for heavy metal solid waste and treatment furnace

PendingCN110257637AHigh recovery rateReduce dosageFurnace typesProcess efficiency improvementMelting tankSlag

The invention discloses a high-efficiency treatment method for heavy metal solid waste and a treatment furnace. The treatment furnace internally provided with a smelting zone, a reducing zone and a clarification separating zone is adopted, and the furnace cylinder depth of the clarification separating zone is large; undercurrent jet combustors horizontally inserted into a slag layer are symmetrically arranged on the two sides of a molten pool of the smelting zone; the reducing zone is provided with a plurality of reducing spraying guns vertically inserted into melt from the furnace body top and adjustable in insert-in depth; the reaction atmosphere is completely isolated between the smelting zone and the reducing zone through a partition wall; materials are continuously added into the smelting zone from a material adding port, oxygen-rich air and fuel are sprayed in from a primary air port of the smelting zone, the process of melting of materials, decomposition and desulfurization of sulfate, slag making and reducing of part of metal is completed, and the melt flows into the reducing zone from a channel below the partition wall; and the reducing spraying guns are used for spraying pulverized coal into the melt so that heavy metal oxide in the melt is reduced into metal to enter a metal phase, the melt flows into the clarification separating zone to form obvious phase interfaces for corresponding discharging, and harmless and comprehensive recycling of resource of the heavy metal solid waste is completed in the treatment furnace.

Owner:CINF ENG CO LTD

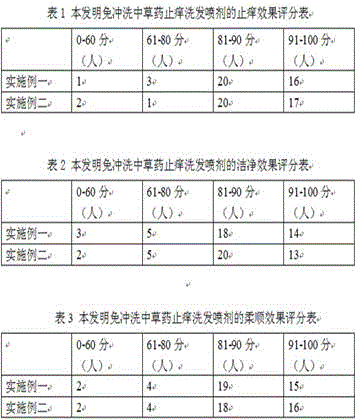

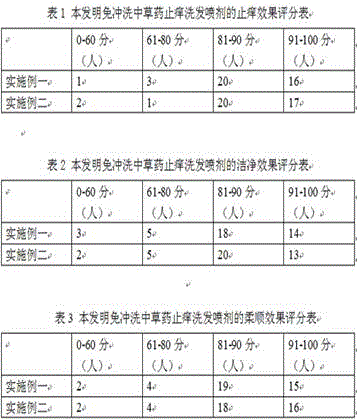

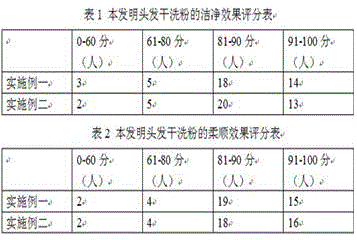

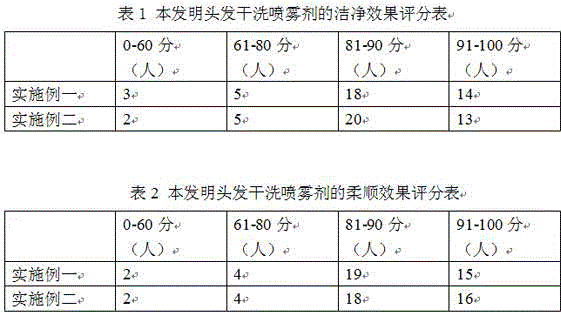

Washing-free itching-relieving Chinese herb hair washing spray

InactiveCN105662978AStrong adsorption functionFast adsorptionCosmetic preparationsHair cosmeticsChemical industryMedicine

The invention discloses a rinse-free Chinese herbal medicine antipruritic shampoo spray, which relates to the technical field of daily chemical industry. This non-flushing Chinese herbal medicine antipruritic shampoo and spray contains the following raw materials in parts by weight: 10 to 20 parts of activated clay powder of 50 to 100 meshes, 0.5 to 0.5 parts of one or more mixtures of cetearyl alcohol and its derivatives 3 parts, 1-2 parts of Senecio extract, 1-2 parts of dandelion extract, 1-2 parts of wild chrysanthemum flower extract, 1-2 parts of Sophora flavescens extract, 0.3-1 part of essence, methyldiethanolamine type double Ester-based quaternary ammonium salt DEEDMAC 0.02-0.06 parts. The invention solves the problems of unsustainable cleanliness, itchy head and severe knotting of hair.

Owner:龙璋

Spinning bobbin

The invention discloses a spinning bobbin which comprises a bobbin body and two annular bobbin covers. The bobbin body comprises an aluminum alloy outer pipe and a stainless steel inner pipe sleeved in the outer pipe. A plastic flexible strip is fixed on each annular bobbin cover. A plurality of location grooves in the length direction are evenly distributed in the stainless steel inner pipe in the circumferential direction, and protruding strips are arranged on the aluminum alloy outer pipe correspondingly. The number of the plastic flexible strips is at least four. Each annular bobbin cover is a phenolic aldehyde plastic pipe cover. Due to the fact that the plastic flexible strips are installed on the bobbin covers, the problem of knotting of a spinning machine in the spinning process is solved, and working efficiency and product quality are improved. The aluminum alloy outer pipe is supported by the stainless steel inner pipe, so that the aluminum alloy outer pipe is not easy to deform, yarn covering production stability is ensured, and bobbin service life is prolonged.

Owner:JIAOZUO LONGRUI TEXTILE MATERIAL CO LTD

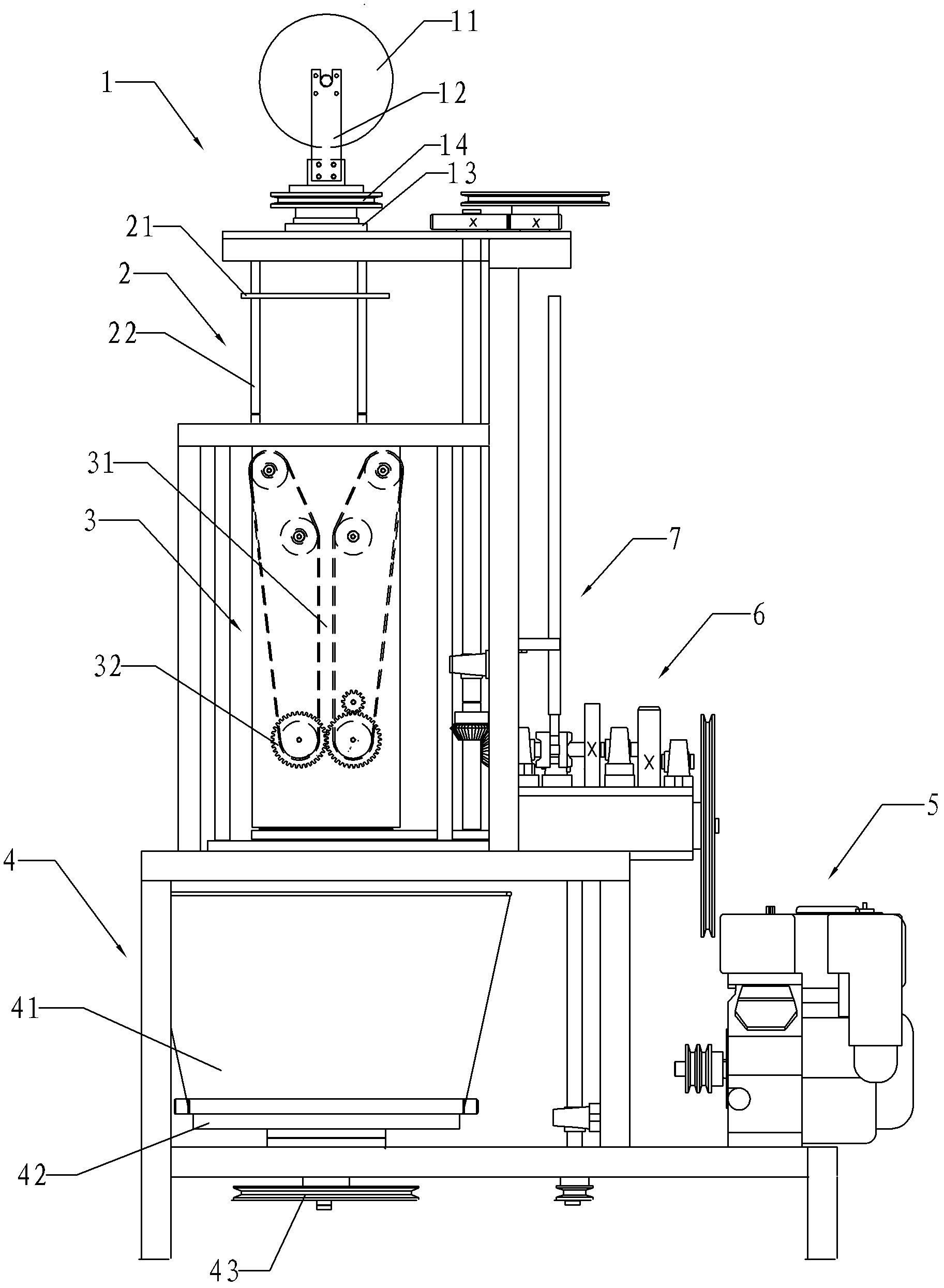

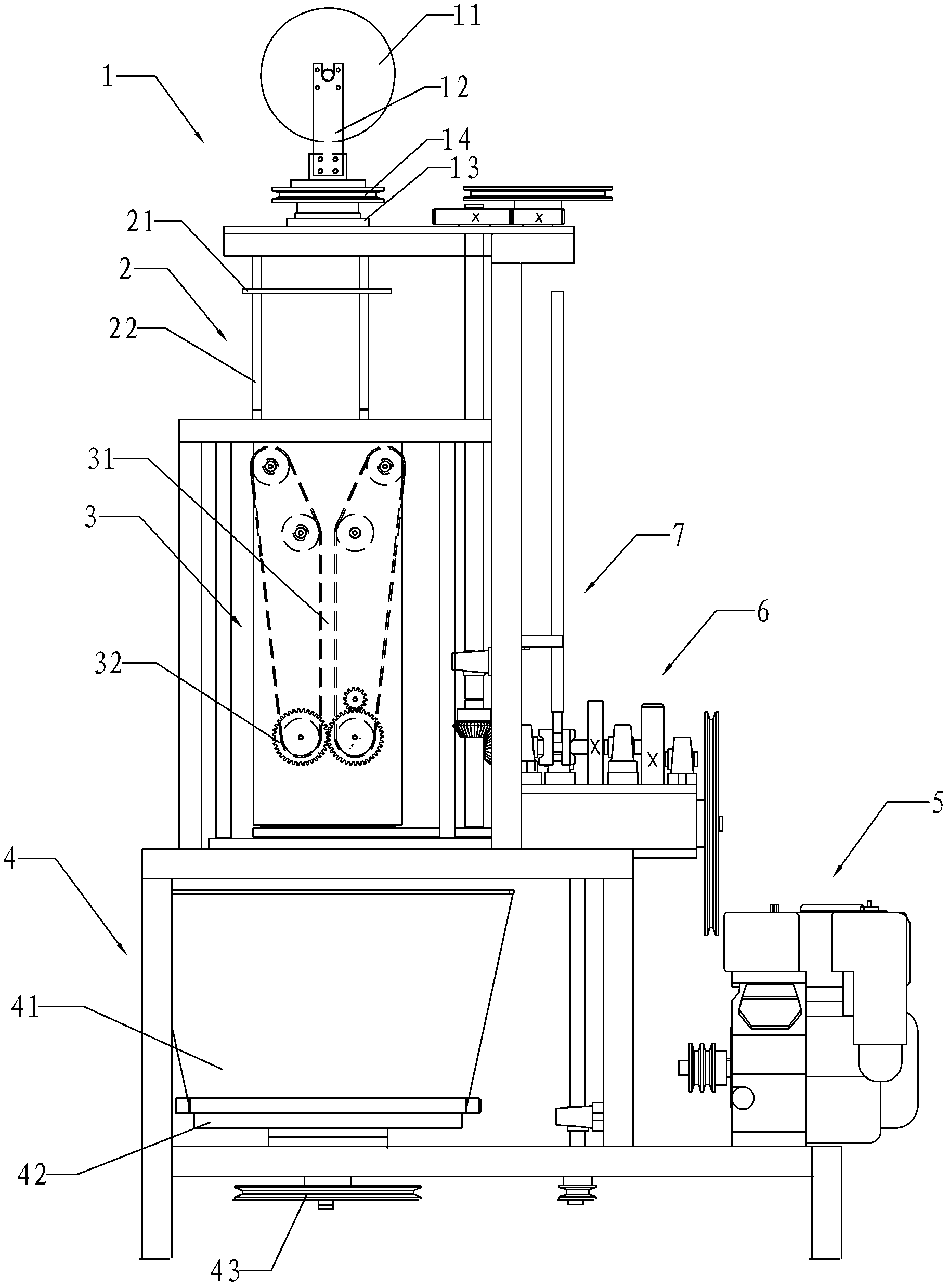

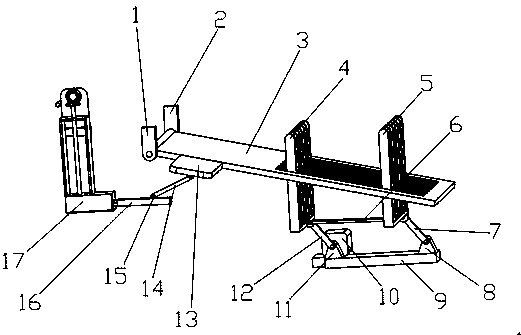

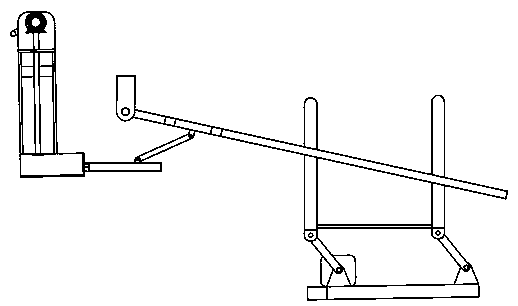

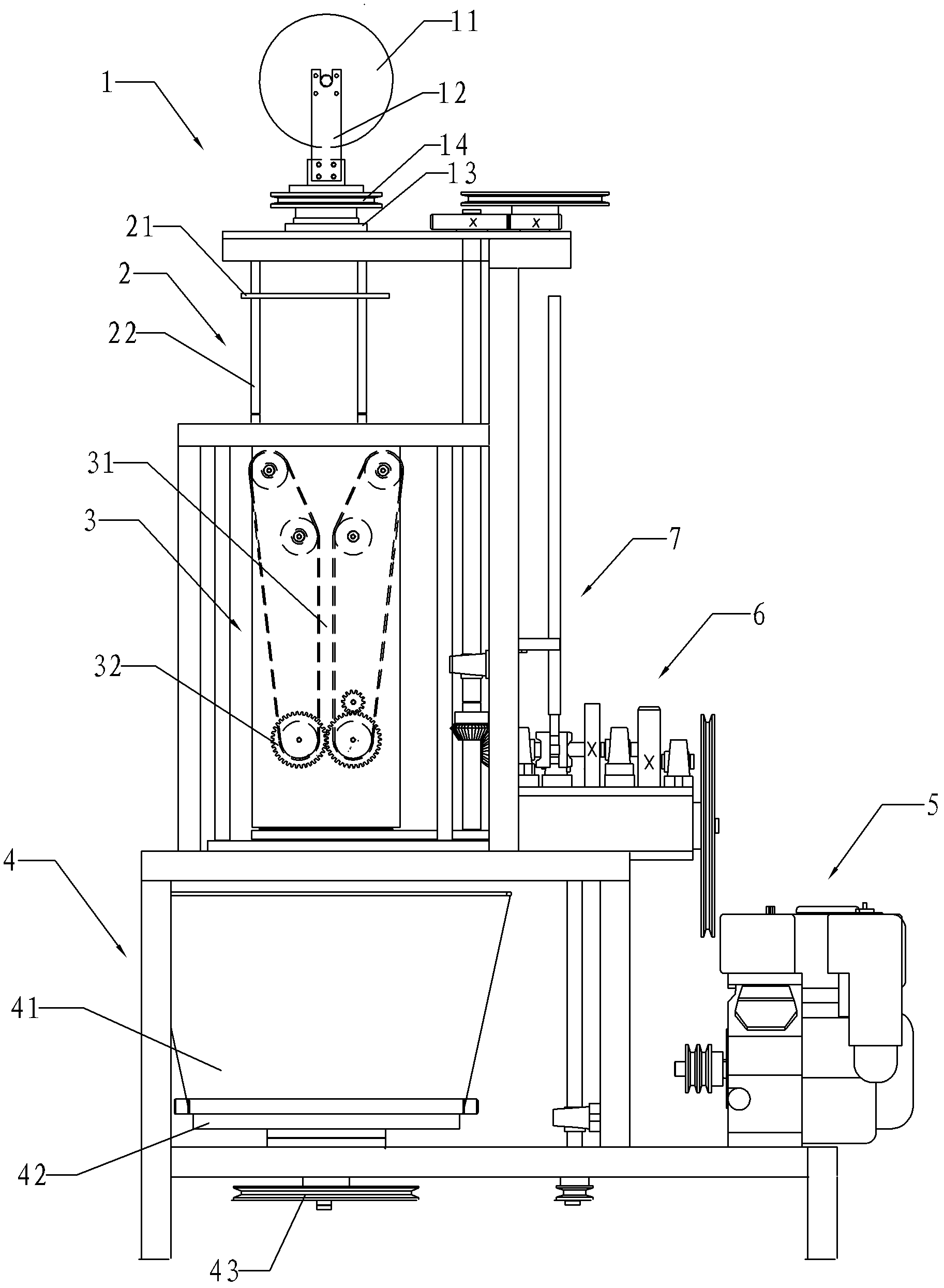

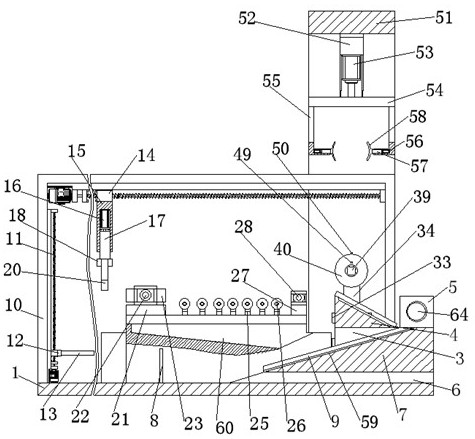

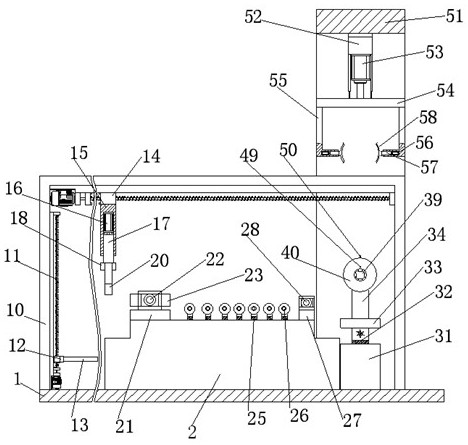

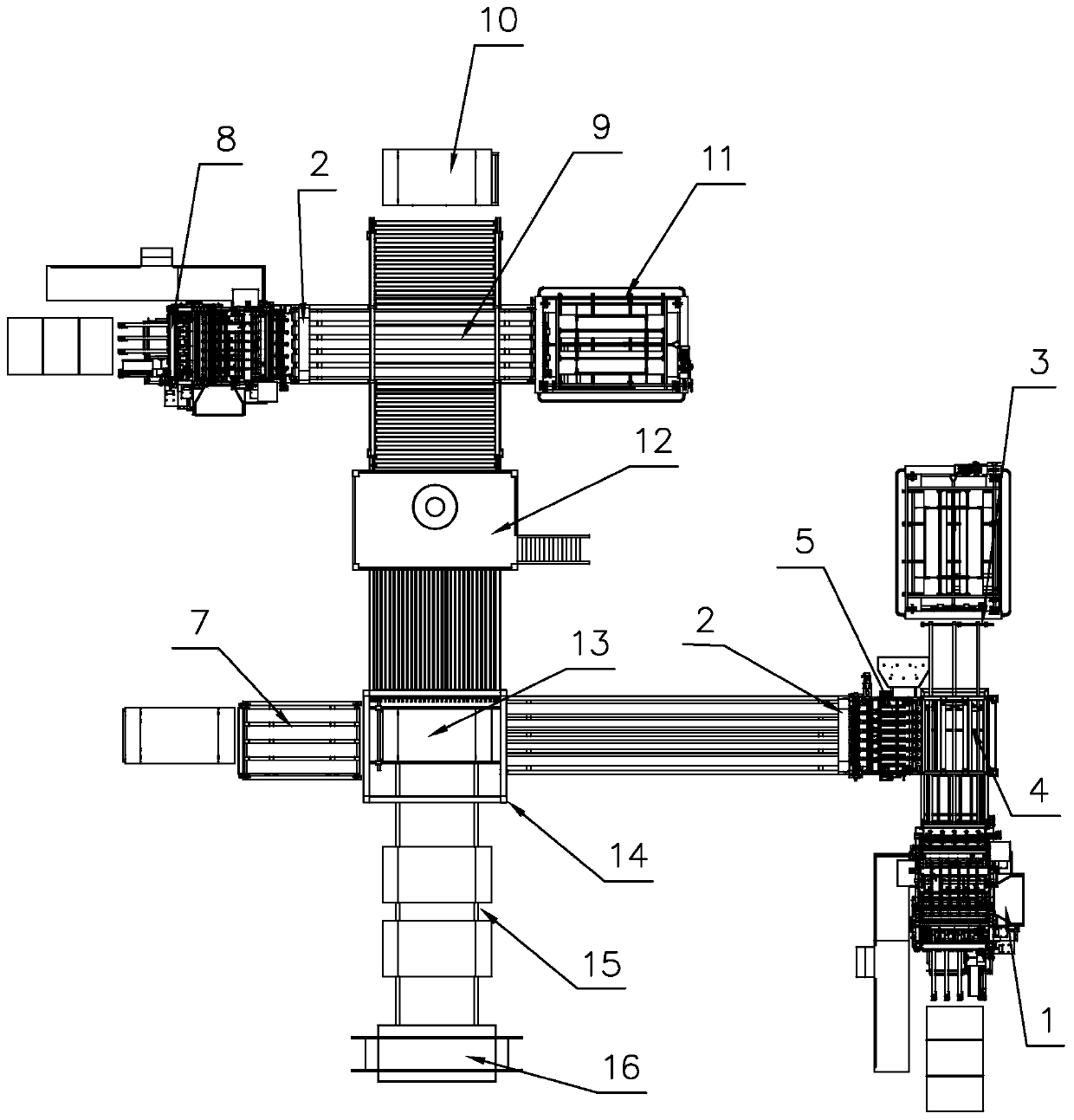

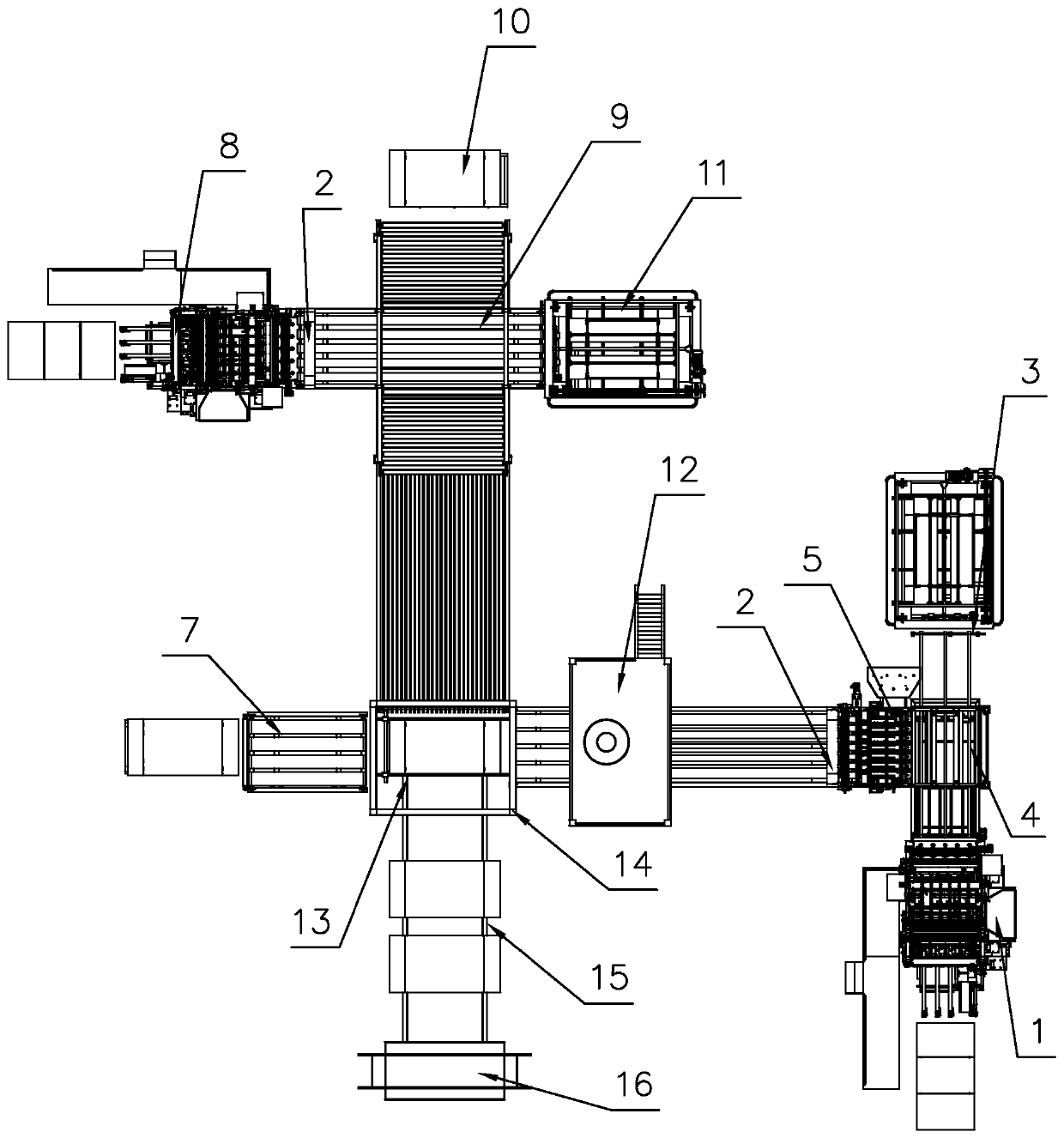

Edible seaweed planting machine

ActiveCN102415327AEasy to collectPlanted firmlyClimate change adaptationCultivating equipmentsAgricultural engineeringMaterial resources

The invention discloses an edible seaweed planting machine, which comprises a frame, wherein the frame is sequentially provided with an unwinding mechanism, a rope distribution mechanism, a conveying mechanism and a receiving mechanism in the transmission direction of a rope; the edible seaweed planting machine also comprises a driving device and a speed changing device; the driving device drivesthe speed changing device to control the unwinding mechanism, the rope distribution mechanism, the conveying mechanism and the receiving mechanism; the conveying mechanism comprises two belt transmission mechanisms; each belt transmission mechanism comprises a driving belt pulley, a driven belt pulley and a belt; the belts of the two belt transmission mechanisms form a feeding passage for connecting the rope distribution mechanism and the receiving mechanism; the driving belt pulleys of the two belt transmission mechanisms rotate at the same speed in opposite directions; and the belt conveying direction of the feeding passage faces the receiving mechanism. The invention aims to provide the edible seaweed planting machine which has the advantages of high automation degree, saving of manpower and material resources, high efficiency and short working time in the edible seaweed planting process and ensures that the planted edible seaweed is fixed firmly with the rope.

Owner:陈敬利

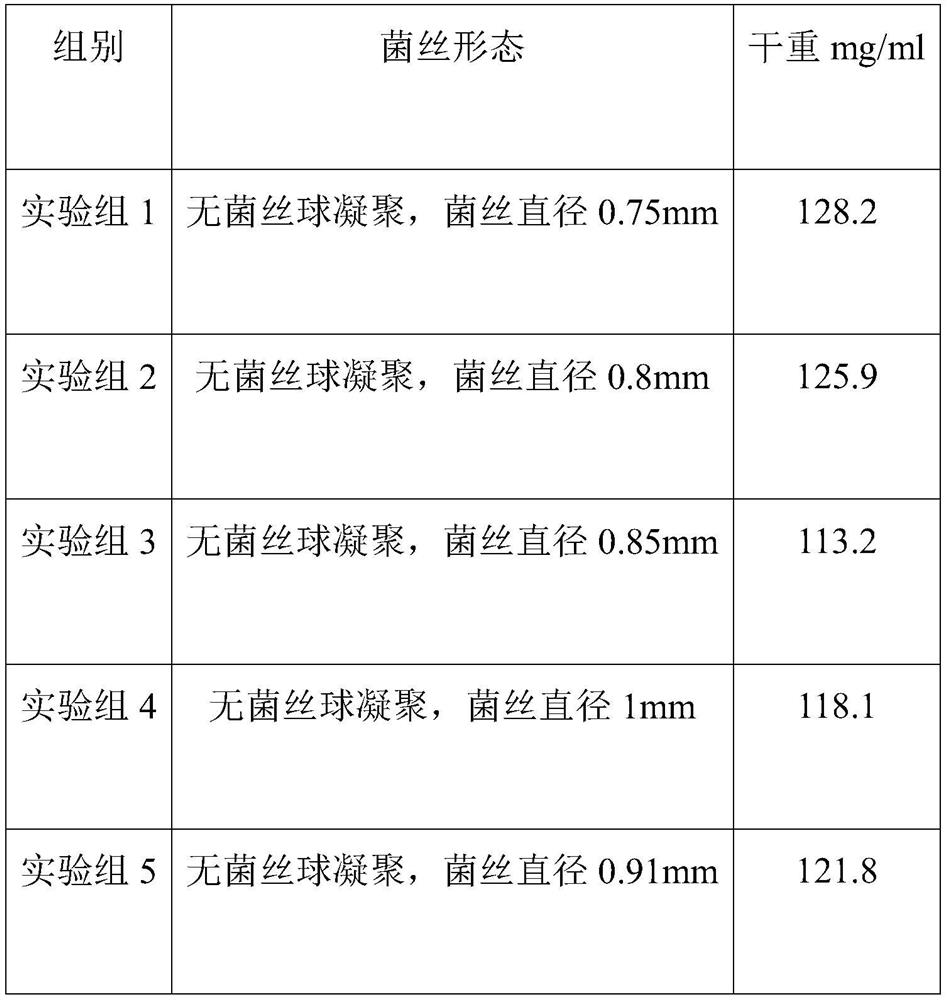

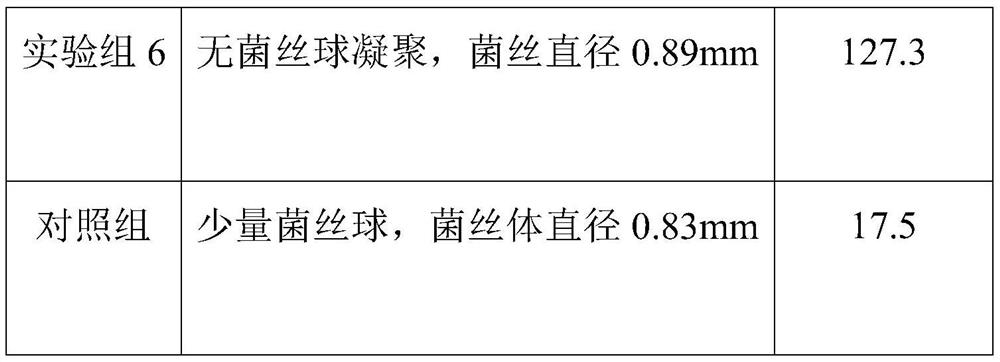

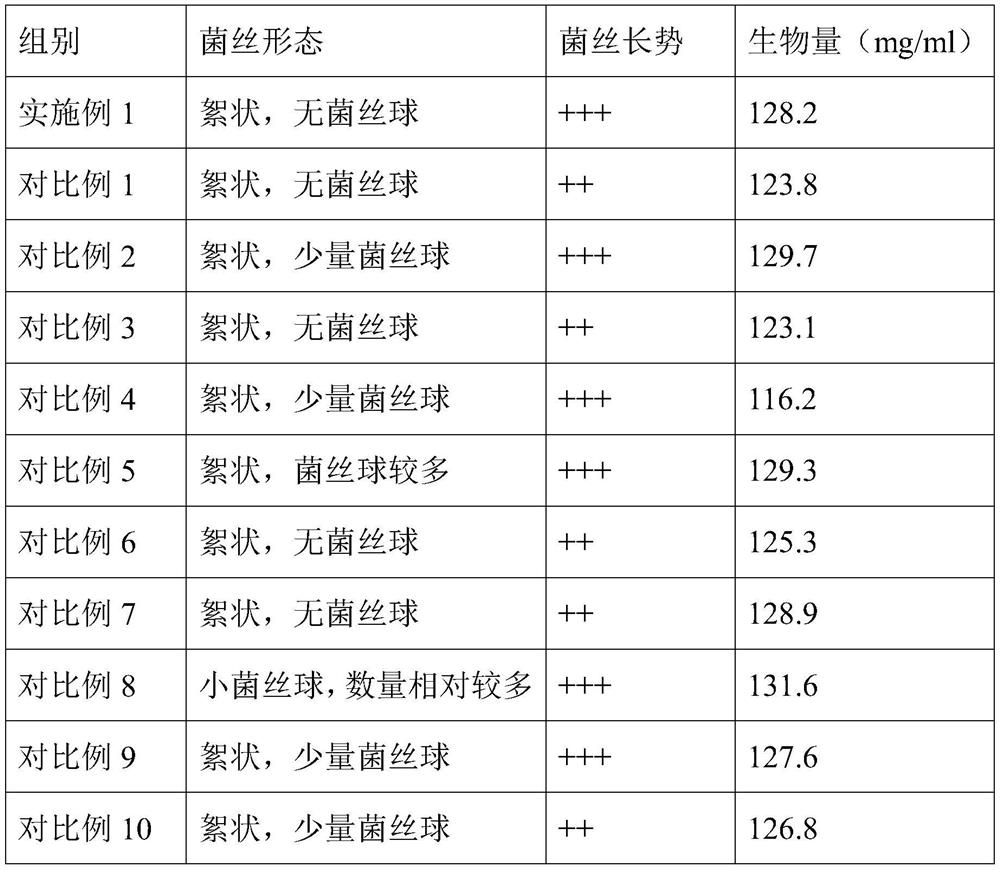

Cultivation method for preventing morchella strains from forming mycelium pellets

PendingCN113647293ASolve the knotMeeting urgent needsCultivating equipmentsMushroom cultivationMyceliumMorchella

The invention belongs to the technical field of biology, and particularly relates to a cultivation method for preventing morchella strains from forming mycelium pellets. The method comprises the following steps: (1) preparing morchella mother liquor; (2) preparing a morchella solid culture medium; (3) preparing a morchella seed solution; and (4) preparing morchella liquid strains; The cultivation method scientifically and reasonably overcomes the defect of contradiction between mycelium balling and biomass in actual production, in the prior art, due to incompatibility of a production process, the mycelium balling aspect and the biomass aspect are not matched, and by means of the cultivation method, mycelium balling is avoided, biomass is improved to the maximum extent, the problems of non-uniform dissolved oxygen and blockage are avoided, and the urgent demand of the market on the morchella is met to the greatest extent.

Owner:重庆云海百草农业科技有限公司

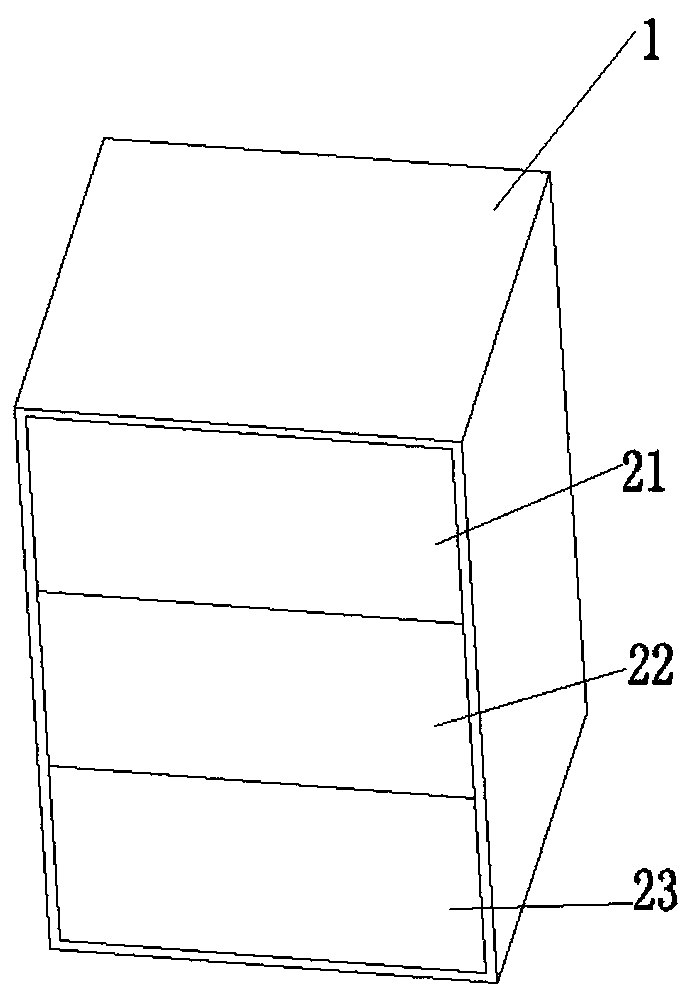

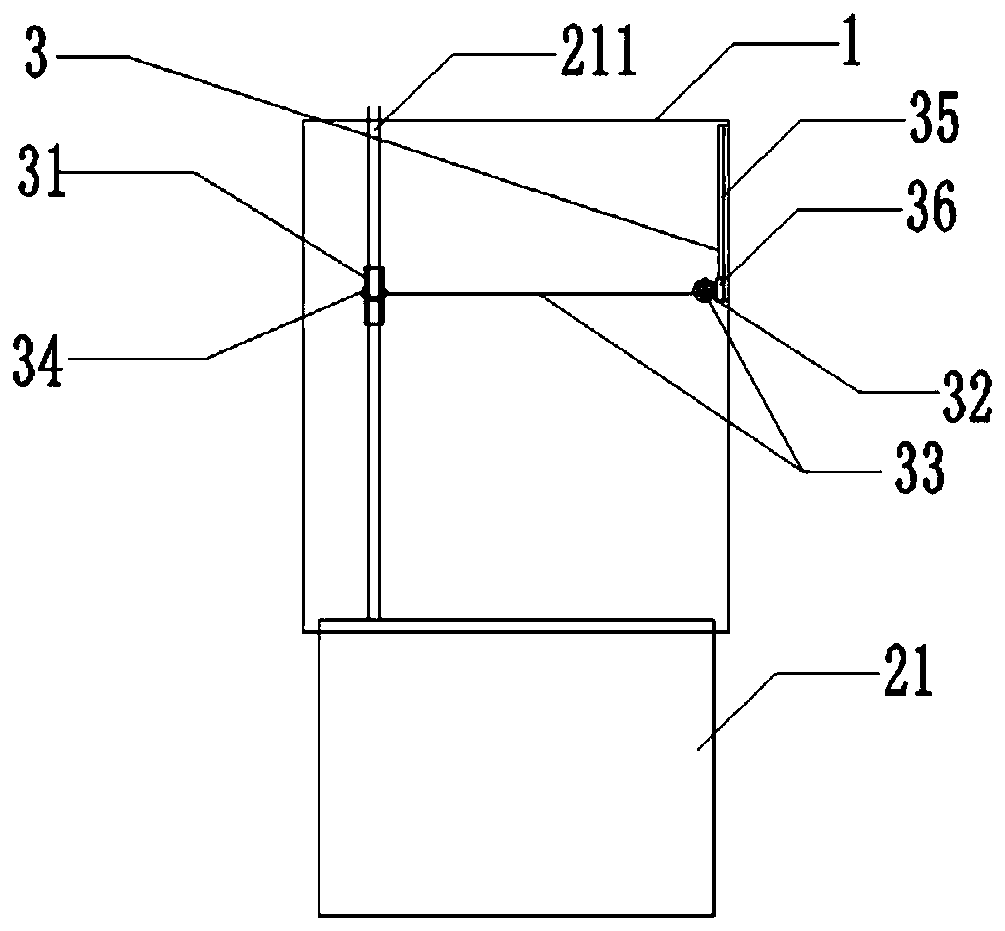

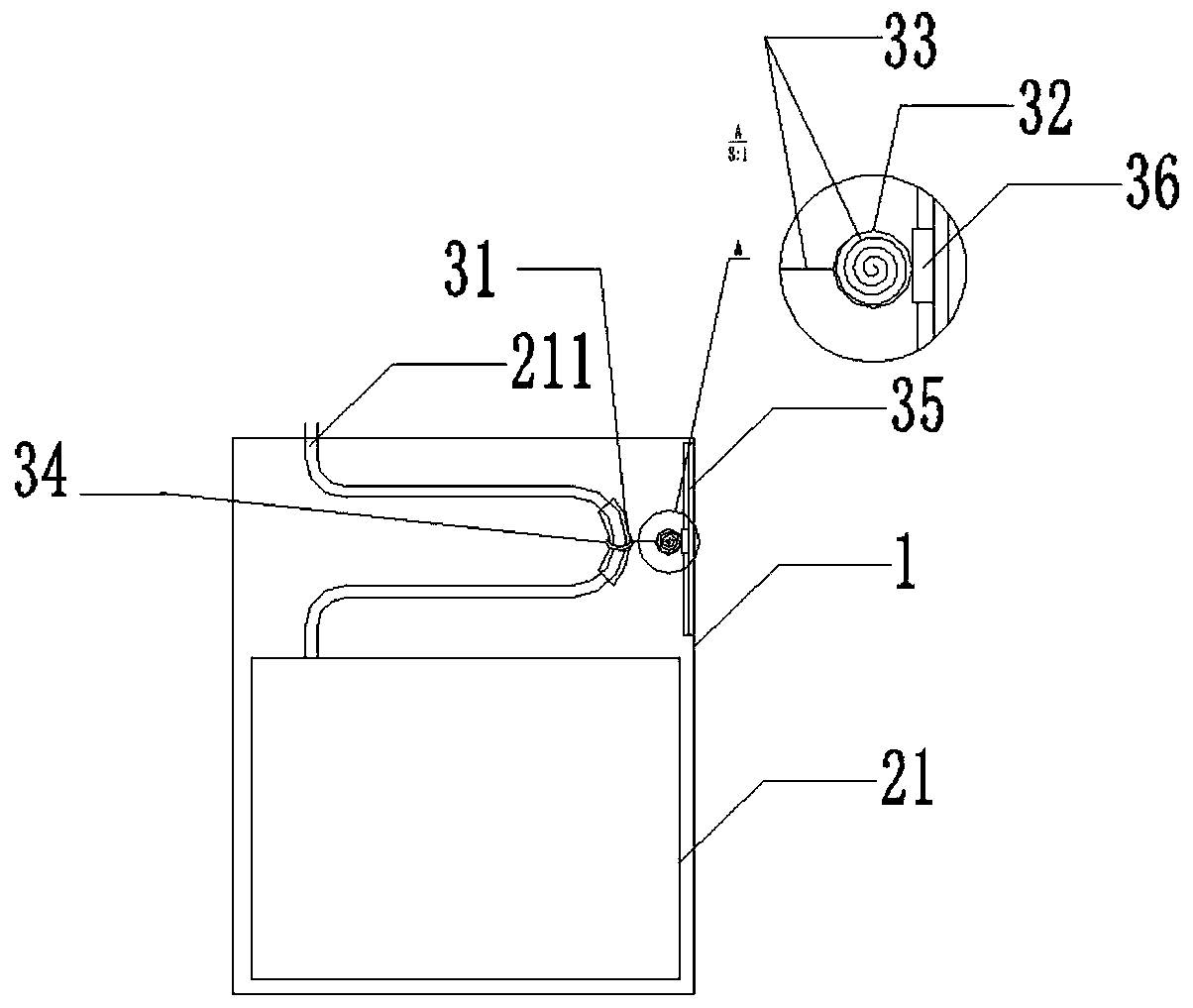

Drawer-type washing device and washing machine with same

PendingCN111235810AImprove wear and deformationImprove the problem of cross infectionOther washing machinesWashing machine with receptaclesLaundry washing machineStructural engineering

The present invention provides a drawer-type washing device and a washing machine with the same. The drawer-type washing device comprises a box body and a telescopic elastic connecting assembly, wherein the inner wall of the box body defines an inner cavity; the inner cavity is internally provided with a drawer that can be pulled, and a washing zone is formed in the drawer; the drawer is providedwith a drainage hole communicating with the washing zone, and the drainage hole is connected with a drainage pipe extending from the drawer; and the telescopic elastic connecting assembly is connected between the drainage pipe and the inner wall of the box body, and the telescopic elastic connecting assembly ensures that the drainage pipe can be stretched along with the drawer in a process of pulling the drawer. The problems that the drainage pipe of an existing washing device is worn and knotted, clothes are subjected to mixed washing, the clothes are worn and water is remained in inner andouter buckets of a washer are solved.

Owner:GREE ELECTRIC APPLIANCES INC

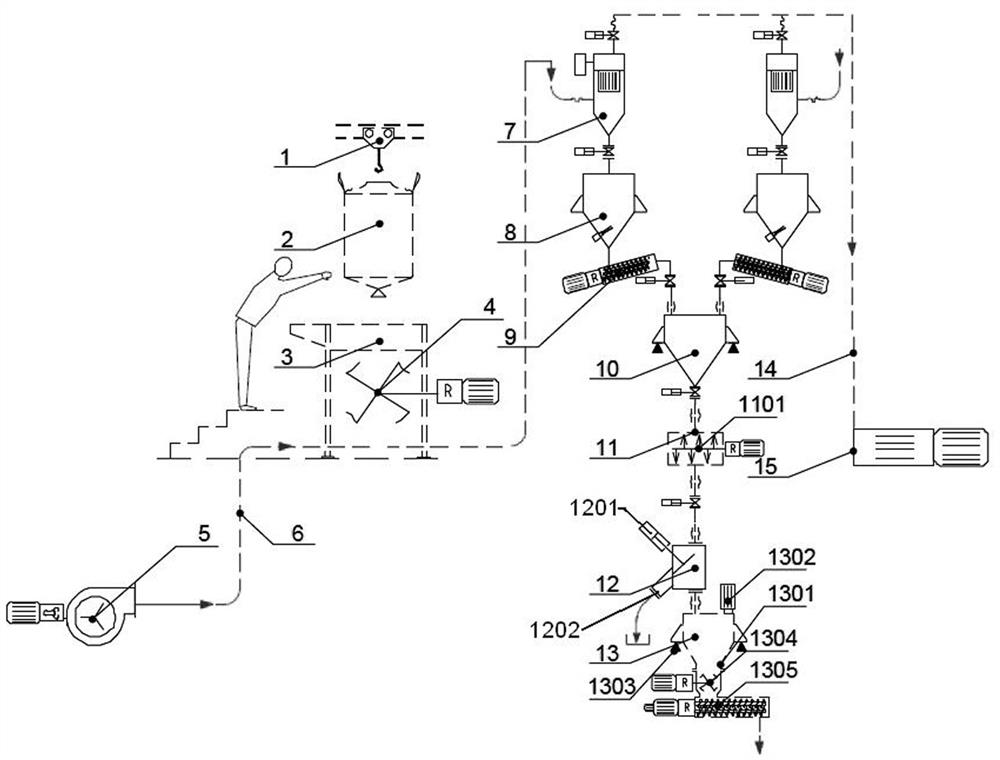

Powder flowing system of lithium ion battery diaphragm

ActiveCN113694803AStable deliverySolve the knotRotary stirring mixersMixer accessoriesThermodynamicsEngineering

The invention discloses a powder flowing system of a lithium ion battery diaphragm. The powder flowing system comprises a bag throwing station, two material-gas separators and a vacuum pump, wherein an air blower is arranged below the bag throwing station, a vacuumizing opening is formed in the top of each material-gas separator, a feeding opening is formed in the side face of each material-gas separator, a discharging opening is formed in the bottom of each material-gas separator, and a stirring device is arranged on the wall face of the bag throwing station. A feeding port of one material-gas separator is connected with a discharging port of a bag throwing station through a pipeline, a feeding port of the other material-gas separator is connected with an additive storage tank through a pipeline, vacuumizing ports of the two material-gas separators are connected with a vacuum pump through pipelines respectively, a buffer hopper is arranged below each material-gas separator, a double-screw conveyor is arranged at an outlet of each buffer hopper, a batching scale is arranged on the lower portion of each buffer hopper, two batching screws meshed in the same direction are arranged in each double-screw conveyor, outlets of the two double-screw conveyors are communicated into the batching scales, and a stirring bin, a metal separator and a feeding weightlessness scale are sequentially arranged below each batching scale from top to bottom.

Owner:SINOMA LITHIUM BATTERY SEPARATOR CO LTD

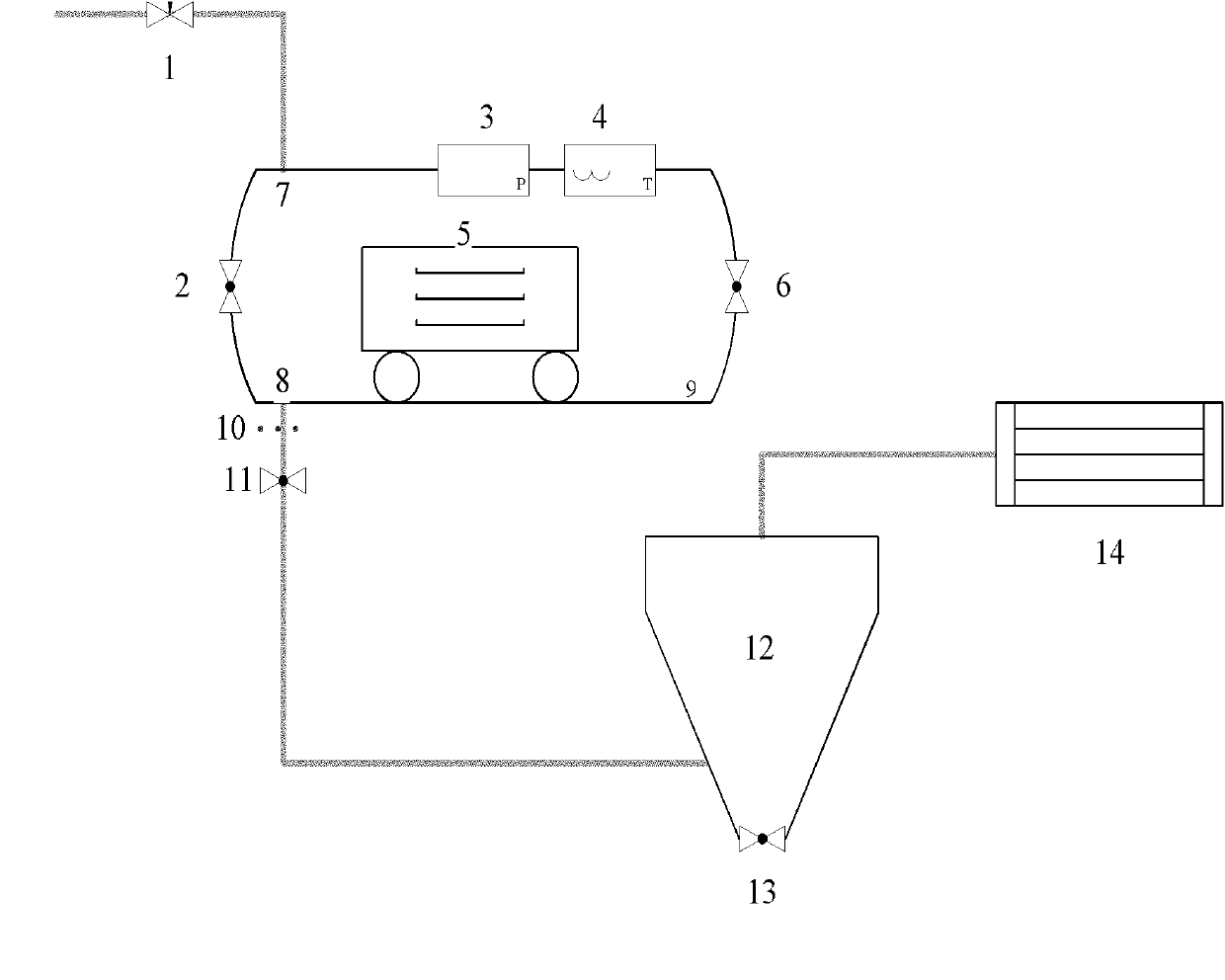

In-situ steam explosion method and device

InactiveCN102166496BAvoid damageSolve the entanglementPressurized chemical processRaw material pretreatmentFiberEngineering

The invention relates to an in-situ steam explosion method, which is characterized in that the raw materials are subjected to explosion in a steam explosion reactor, then the escaped gas is fed into a gas condensation and recycling system and the remaining materials are kept in situ in the steam explosion reactor. The in-situ steam explosion device comprises a horizontal cylindrical tank; the upper wall of the tank is provided with a pressure gauge, a thermometer and a steam inlet, and the lower wall of the tank is provided with a steam outlet; two ball valves respectively arranged at the two sides of the tank are respectively used as a charging-car inlet and a charging-car outlet; and in the box-type or cage-type reticular charging car with wheels, a steel-mesh plate is arranged in front of a pneumatic ball valve of a steam outlet pipeline, the rear part of the steam outlet pipeline is connected with a buffer vessel and a gas condensation and recycling system, and the bottom of the inside of the buffer vessel is provided with an axial fixed orbit which facilitates the getting-in-and-out of the charging car. By using the device disclosed by the invention, the problems that the winding and knotting of fibrilia materials in the process of discharging, the difficulties and loss in raw material recycling, and the heat waste, environmental pollution, wasting of resources and troubles brought to experimental analysis which are caused by directly emitting the steam to the atmosphere and can not be solved by using the existing steam explosion technology and equipment are solved effectively.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Vegetable fat hair conditioner and preparation method thereof

InactiveCN113304073APromotes the absorption of nutrientsPromote blood circulation and metabolismCosmetic preparationsHair cosmeticsHair conditionerHair dyes

The invention discloses a vegetable fat hair conditioner. The vegetable fat hair conditioner comprises an A-phase component, a B-phase component, a C-phase component and a D-phase component, the vegetable fat hair conditioner can effectively solve the problem of hair knotting, enables hair to fully absorb nutrition, forms a protective layer outside the hair, prevents the hair from being damaged, keeps the hair soft and glossy, is easy to comb and antistatic, and enables mechanical damage of the hair and damage caused by chemical ironing, electric ironing and hair dye to be repaired to a certain extent.

Owner:广州黛莱美化妆品有限公司

Manufacturing method for leave-in itching-relieving Chinese herbal medicine hair washing spray

InactiveCN105796403AImprove nutritional statusEasy to combCosmetic preparationsHair cosmeticsChemical industrySerenoa repens extract

The invention discloses a manufacturing method for leave-in itching-relieving Chinese herbal medicine hair washing spray, and relates to the technical field of daily-use chemical industry.The manufacturing method for the leave-in itching-relieving Chinese herbal medicine hair washing spray includes the following steps that 1, cetostearyl alcohol is added into a reaction kettle and heated to 48-50 DEG C to melt; 2, climbing groundsel herb extract, dandelion extract, wild chrysanthemum flower extract, matrine extraction, essence, amide esterquat EAAQ, water-soluble wool grease and vitamin B5 are added, melted and stirred uniformly; 3, activated clay powder is added and stirred uniformly; 4, heating is stopped, and the mixture is cooled; 5, the mixture is ground to 50-100 meshes and packaged to obtain the leave-in itching relieving hair washing spray.The leave-in itching-relieving Chinese herbal medicine hair washing spray solves the problems that cleanliness is unabiding, the scalp itches and hair knots seriously.

Owner:龙璋

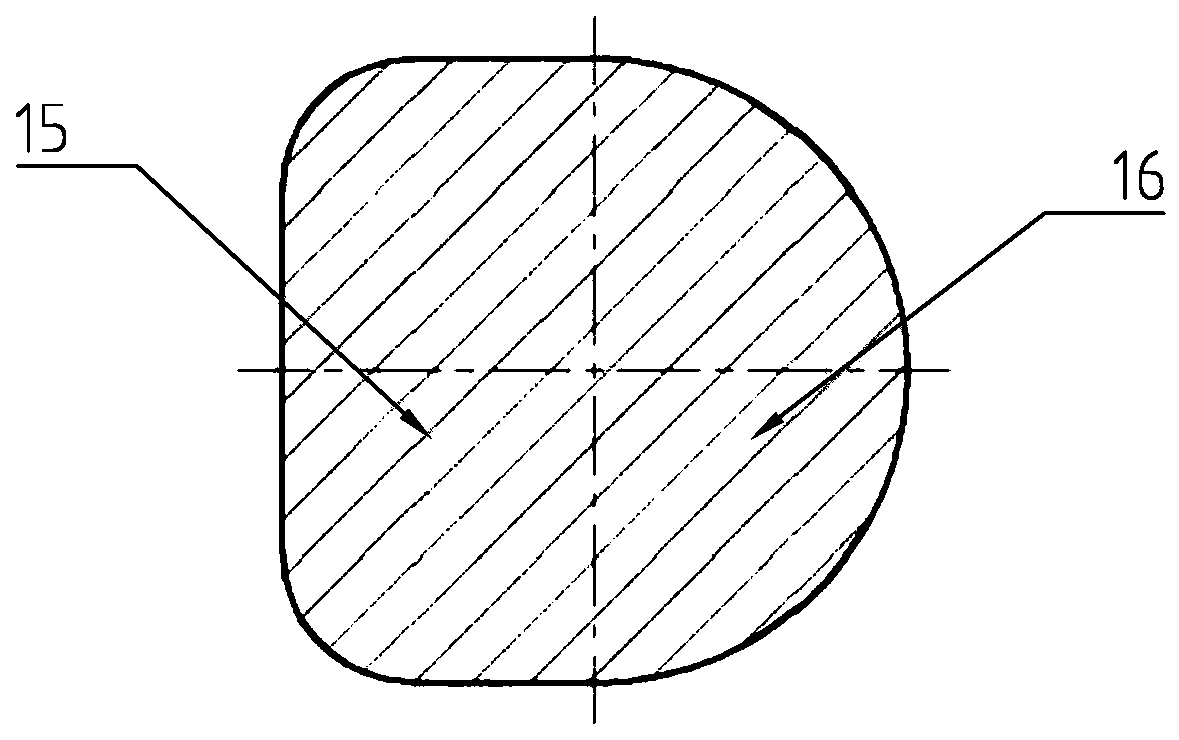

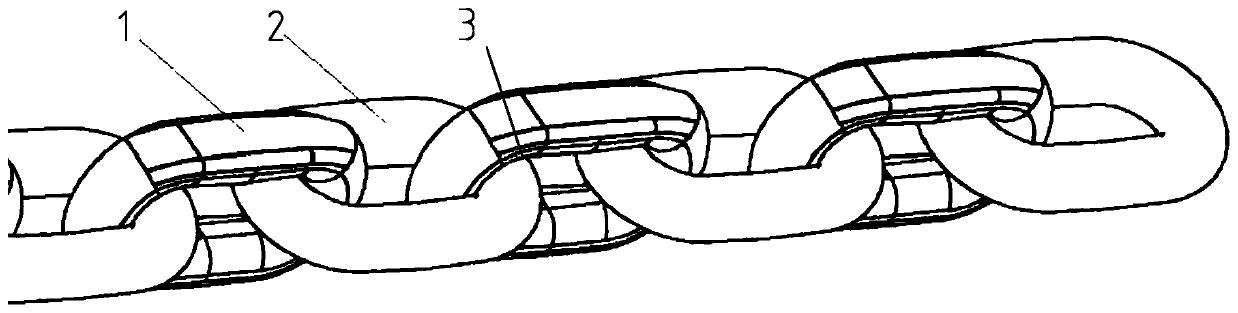

Single-side type anti-knotting compact chain vertical ring

PendingCN110203620ATurn freelyImprove mechanical propertiesConveyorsHauling chainsFree rotationFree state

The invention relates to the technical field of mine high-strength compact chains, in particular to a single-side type anti-knotting compact chain vertical ring. In order to solve the chain knotting problem and the chain blocking problem, chain blocking is mainly caused by mutual free displacing and rotating between a flat ring and the vertical ring while a chain is in a free state, and a great thickness of a straight arm of the vertical ring. A baffle block which is bulged towards the inner side is arranged on the middle position of a first straight arm of the vertical ring. By virtue of thebaffle block, the flat ring is always in a relatively small thickness range region of the vertical ring, so that free rotation between the flat ring and the vertical ring is guaranteed, and the knotting problem and the knot-blocking problem of a compact chain are solved; and the vertical ring changes the shape of the section of the circular-arc part of the end part, so that mechanical property ofthe vertical ring is greatly improved.

Owner:长春东北输送设备制造有限公司

Long hair smoothing mechanism of long hair smoothing and blow-drying bed

The invention relates to a long hair smoothing mechanism of a long hair smoothing and blow-drying bed, and belongs to the technical field of household devices. The long hair smoothing mechanism comprises a first long hair lifting plate hinging block, a second long hair lifting plate hinging block, a long hair lifting plate, first smoothing teeth, second smoothing teeth, a smoothing tooth connecting rod, a second smoothing tooth hinging rod, a second smoothing tooth hinging rod hinging block, a motor supporting plate, a deceleration motor, a first smoothing tooth hinging rod hinging block, a first smoothing tooth hinging rod, a long hair lifting plate extending plate, a long hair lifting plate lifting hinging rod, a hinging sliding block, a sliding groove, a gear lead screw transmission mechanism, a lead screw, a threaded block, and a long hair lifting plate lifting rocking handle. The problem of hair knotting in the hair drying process of women with long hair is solved.

Owner:贵港市庄满园农业服务有限公司

Dry cleaning powder for hair

InactiveCN105616209AStrong adsorption functionFully contactedCosmetic preparationsHair cosmeticsChemical industryActivated carbon

The invention discloses a dry cleaning powder for hair and relates to the technical field of daily chemical industry. The dry cleaning powder for hair is prepared from, by weight, 10-20 parts of 50-100-mesh activated carbon powder, 0.5-3 parts of hydrogenated castor oil, 0.3-1 part of essence and 0.02-0.06 part of amide-ester-based quaternary ammonium salt EAAQ. The dry cleaning powder for hair solves the problems that cleanliness is transient and hair is seriously knotted.

Owner:龙璋

Edible seaweed planting machine

ActiveCN102415327BEasy to collectPlanted firmlyClimate change adaptationCultivating equipmentsAgricultural engineeringMaterial resources

The invention discloses an edible seaweed planting machine, which comprises a frame, wherein the frame is sequentially provided with an unwinding mechanism, a rope distribution mechanism, a conveying mechanism and a receiving mechanism in the transmission direction of a rope; the edible seaweed planting machine also comprises a driving device and a speed changing device; the driving device drivesthe speed changing device to control the unwinding mechanism, the rope distribution mechanism, the conveying mechanism and the receiving mechanism; the conveying mechanism comprises two belt transmission mechanisms; each belt transmission mechanism comprises a driving belt pulley, a driven belt pulley and a belt; the belts of the two belt transmission mechanisms form a feeding passage for connecting the rope distribution mechanism and the receiving mechanism; the driving belt pulleys of the two belt transmission mechanisms rotate at the same speed in opposite directions; and the belt conveying direction of the feeding passage faces the receiving mechanism. The invention aims to provide the edible seaweed planting machine which has the advantages of high automation degree, saving of manpower and material resources, high efficiency and short working time in the edible seaweed planting process and ensures that the planted edible seaweed is fixed firmly with the rope.

Owner:陈敬利

A long-hair smoothing and blow-dry bed

The invention relates to a long hair smoothing and blowing drying bed, belonging to the technical field of household devices. The long hair smoothing and blowing drying bed comprises a long hair smoothing mechanism and a bed body, wherein the invention solves the problems that the hair of a long-haired woman is knotted in the hair drying process, the hair of a long-haired woman is not easy to be dried in the hair drying process, and the like.

Owner:贵港市庄满园农业服务有限公司

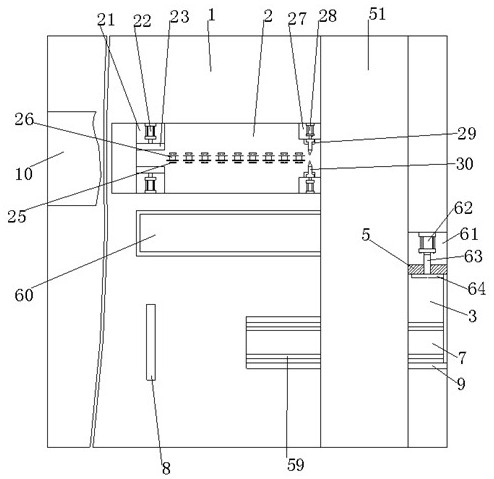

Cable raw material cutting, winding and rolling full-automatic production equipment

The invention discloses cable raw material cutting, winding and rolling full-automatic production equipment. The production equipment comprises a base plate, wherein a cushion table is installed on the base plate, an intelligent movable jacking mechanism, a wiping and supporting sliding structure, intelligent cutting structures, an intelligent movable winding mechanism and an intelligent movable material taking and inserting mechanism are installed on the cushion table, the fixed supporting structure is fixed on the base plate and is positioned below the intelligent movable jacking mechanism, the intelligent cutting structures are fixed to the cushion table and located on the two sides of the fixed supporting structure, the intelligent movable winding mechanism is fixed on the base plate and is positioned on one side of the cushion table, and the intelligent movable material taking and inserting mechanism is fixed to the base plate and located above the intelligent movable jacking mechanism. The invention relates to the field of cable raw material processing. The production equipment has the beneficial effects that due to the adoption of the intelligent movable jacking mechanism, the problems of knotting in the traction process of stacked cable raw materials and manual traction are effectively solved.

Owner:鑫盛泓达(徐州)智能科技发展有限公司

Impregnation rolling process of plant treatment fire-proof plate

ActiveCN102672770BLight weightAnti-corrosionDomestic articlesFlat articlesPlant fibreProcess engineering

The invention discloses a dipping and rolling process for a plant fiber fireproof board, comprising the following steps: A. using a paving machine to make a slab with plant fiber silk as a raw material through the paving process, and the density of the slab is 0.1 to 0.2g / cm3; B. Soak the slab in the inorganic gelling slurry with a mass percentage concentration of 50% to 70%; C. Roll the soaked slab; D. Make the rolled slab through curing and drying, etc. into plant fiber fireproof panels. The inorganic gelling slurry is a slurry formed by mixing magnesium chloride, magnesium oxide and water. Due to the above-mentioned production process, not only the board has the characteristics of light weight, anti-corrosion, easy processing, and low cost, but also adds fireproof performance, and at the same time increases the strength of the board; the use of this process also solves the problem of long fiber winding in At the same time, the phenomenon of knotting or entanglement occurs, thereby ensuring the production efficiency of the board and improving the quality of the processed board.

Owner:GUANGDONG YIXIN HOUSEHOLD MATERIALS GROUP CO LTD

Multilayer plate full-automatic double-machine production line

InactiveCN110216750ASimplify the traditional production processReduce labor intensityWood veneer joiningProduction lineAgricultural engineering

The invention discloses a multilayer plate full-automatic double-machine production line comprising a single plate vertical splicing transverse-splicing mechanism, a finished product visual angle detection mechanism, a 4-4 dimension single plate reject separation mechanism, a 90-degree steering mechanism I, a 4-8 dimension single plate vertical splicing mechanism, a 4-8 dimension single plate transverse splicing mechanism, a 90-degree steering mechanism II, a 4-8 dimension single plate reject separation mechanism, a single plate automatic gluing mechanism, a glue plate assembly mechanism, a stacking mechanism, an automatic conveying mechanism and a full-automatic cold pressing mechanism. Through the multilayer plate full-automatic double-machine production line, assembly line production from single plate arrangement to assembly cold pressing is achieved, the traditional multilayer plate production technological process is simplified greatly, product quality of produced single plates isimproved, holes, knots, color difference and other problems existing in single plate production are solved, the production line can meet different production requirements through the layout in two single plate gluing modes, and more optimization adjustment modes can be obtained during production machining.

Owner:山东昶兴智能科技有限公司

Preparation method of carpet type physiotherapy massage liquid

PendingCN114344243AAchieve acid-base balanceResolve cystHydroxy compound active ingredientsAntipyreticSinomeniumWolfiporia extensa

Owner:王成全

Comprehensive utilization method for fly ash of non-calcium roasting rotary kiln

The invention provides a comprehensive utilization method for fly ash of a non-calcium roasting rotary kiln. The method comprises the steps of reducing the alkaline adding quantity on the basis of original non-calcium roasting ingredients; mounting an electrostatic pulse bag deduster at the tail of the rotary kiln, and collecting fly ash into a fly ash collecting pool; arranging a hoister on the fly ash collecting pool, collecting fly ash into a bin of a distribution system of the rotary kiln, calculating the reduced alkaline adding quantity and the increased fly ash quality, and regulating the adding quantity of packing on the premise of keeping the total quantity of the original ingredients and the distribution proportion of chromite unchanged; completely producing chromium salt by using the fly ash through a non-calcium roasting rotary kiln process. According to the invention, the alkaline adding quantity is reduced, and then, the fly ash is recycled and added, so that the ringing problem of the rotary kiln is thoroughly solved, the effect of comprehensively utilizing the fly ash is finally achieved, and the comprehensive utilization method is more economic, more environment-friendly and safest.

Owner:GANSU JINSHI CHEM

Hair dry-cleaning spray

InactiveCN105748327AStrong adsorption functionFully contactedCosmetic preparationsHair cosmeticsChemical industryActivated carbon

The invention relates to the technical field of daily chemical industry and discloses a hair dry-cleaning spray.The hair dry-cleaning spray is prepared from, by weight, 10-20 parts of 50-100-mesh activated carbon powder, 0.5-3 parts of hydrogenated castor oil, 0.3-1 part of essences and 0.02-0.06 part of diester-based propyl quaternary ammonium salt HEQ.The hair dry-cleaning spray solves the problems of short cleanness lasting time and hair knotting severity.

Owner:龙璋

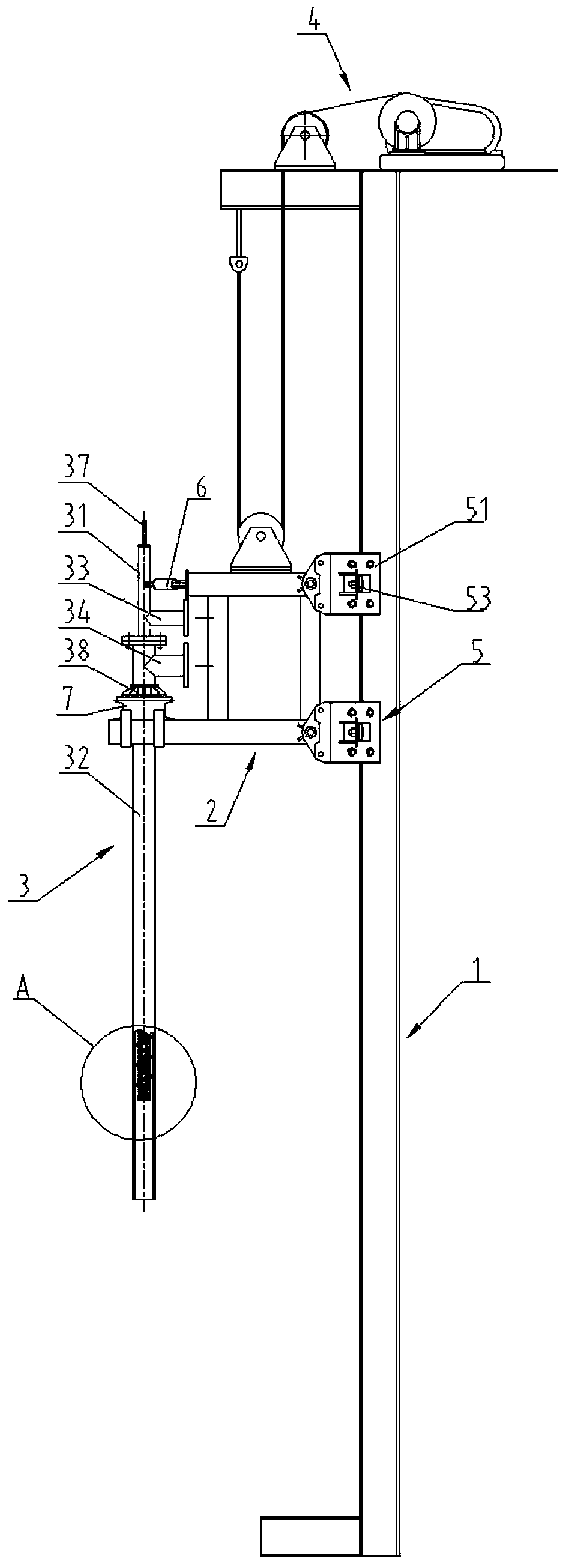

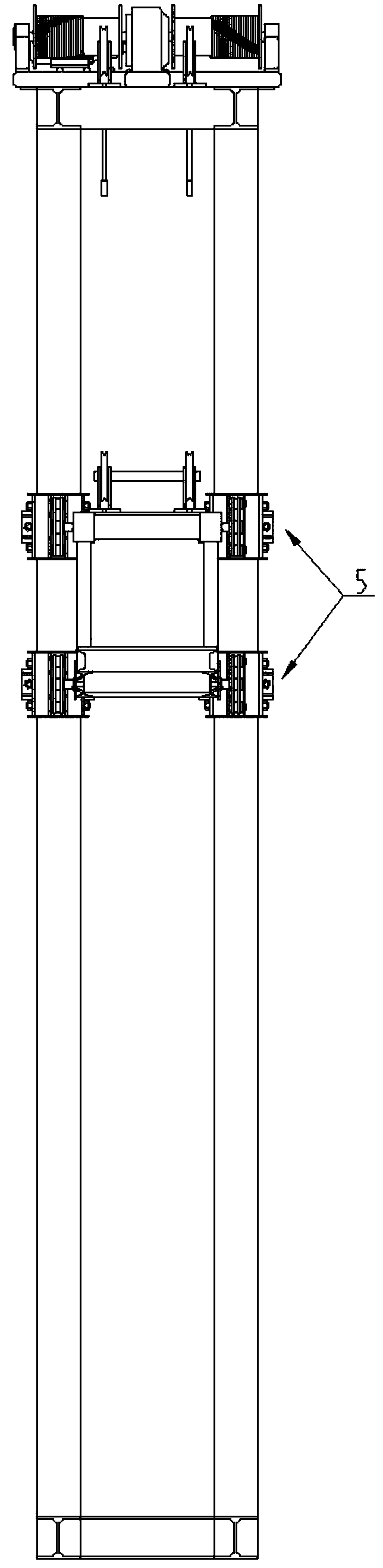

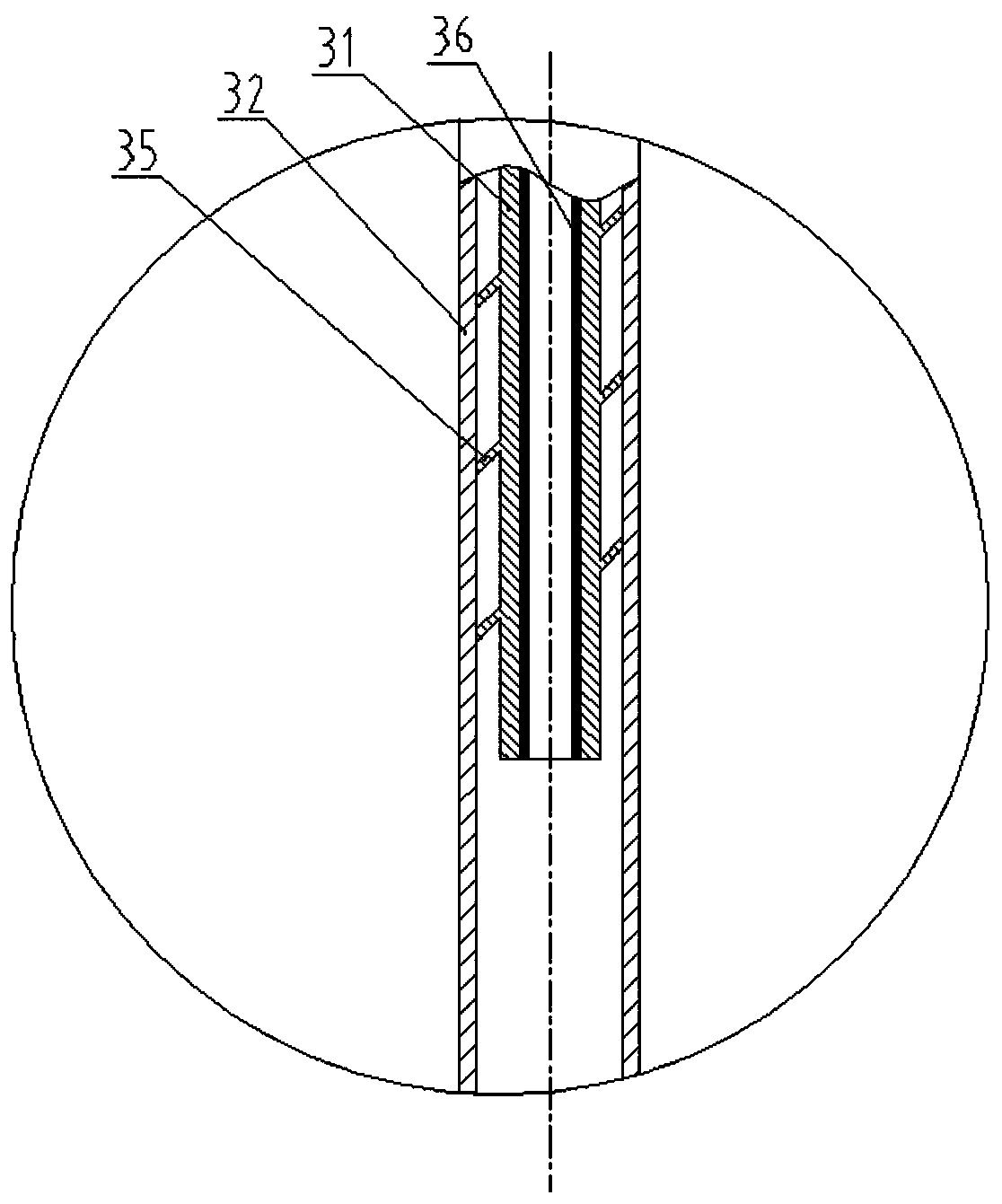

Vertical combustor system capable of ascending and descending and application method thereof

PendingCN110260653AHigh recovery rateSolve the knotCharge treatment typeCrucible furnacesCombustorInsertion depth

The invention discloses a vertical combustor system capable of ascending and descending and an application method of the vertical combustor system capable of ascending and descending. The vertical combustor system capable of ascending and descending comprises a lifting rail, a lifting frame, a combustor and a lifting drive device. A power device of the lifting drive device is fixed to the top of the lifting rail. The lifting frame is connected to the lower end of an action executor of the lifting drive device. Guide wheel devices are connected to one side of the lifting frame. The combustor is fixed to the opposite side of the side connected with the guide wheel devices. A lifting power device works to drive the lifting frame to slide vertically along the lifting rail through the guide wheel devices, so that vertical position change of the combustor is achieved. The heat demands at different heights in different areas of the bottom of a melt can be met by selecting different positions and different insertion depths of the combustor according to needs. The stagnation problem of a metal phase can be solved, and an isolation membrane layer between the metal phase and a slag phase of the melt can be eliminated, a metallic oxide is reduced into metal, the metal enters the metal phase to flow into a clarification separation area of a smelting furnace, metal carried away by slag is reduced, and the recovery rate of the heavy metal is improved. Meanwhile, harmless treatment is conducted on heavy metal solid waste.

Owner:CINF ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com