bobbin for textile

A bobbin and cap technology, applied in the textile field, can solve the problems of increasing the bobbin quality, high energy consumption, and reducing the quality of textiles, and achieve the effects of reducing energy consumption, reducing overall quality, improving work efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

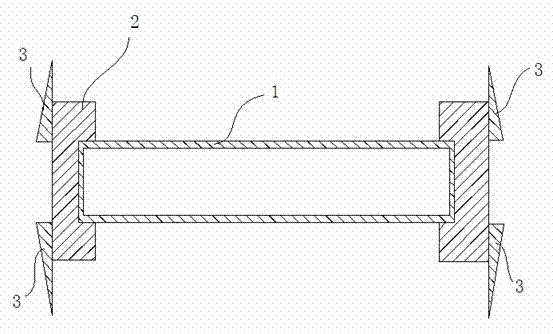

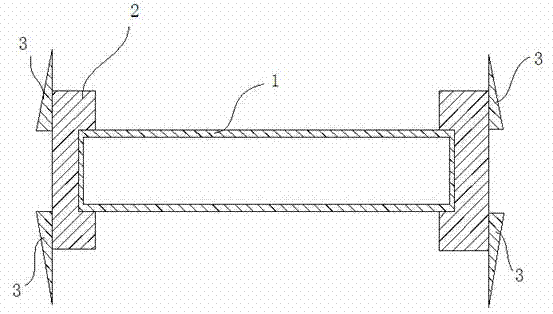

[0012] like figure 1 As shown, a bobbin for textiles comprises a hollow aluminum alloy tube body 1 and two circular tube covers 2 made of plastic material, the circular tube covers 2 are fixed on both ends of the tube body 1, and It includes 4 soft plastic strips 3 which are fixed on the circular pipe cover 2 .

[0013] During the working process of the textile machine, when the spinning thread is too good, because the soft plastic strip 3 has a certain buffer force, it can straighten the too good spinning thread, thereby preventing the spinning thread on the bobbin from being knotted. the goal of.

[0014] The tube body 1 of the bobbin provided by the present invention is hollow and made of aluminum alloy, and the tube cover 2 is made of phenolic plastic, thereby effectively reducing the overall quality of the bobbin and energy consumption.

[0015] To sum up, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com