Dry cleaning powder for hair

A technology of dry cleaning powder and hair, which is applied in the field of daily chemical industry, can solve the problems of unsustainable cleanliness and hair knotting, and achieve the effect of thorough cleaning, long-lasting clean state and super strong adsorption function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

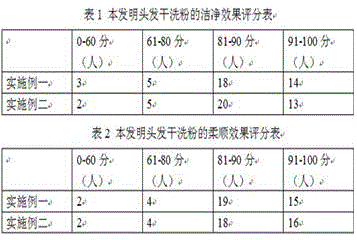

Examples

Embodiment 1

[0012] This hair dry cleaning powder contains the following raw materials in parts by weight: 10 parts of activated carbon powder of 50 to 100 meshes, 0.5 parts of hydrogenated castor oil, 0.3 parts of rose essence, 0.02 parts of amide ester quaternary ammonium salt EAAQ, and 1 part of water-soluble lanolin , vitamin B50.1 parts.

[0013] The production method is as follows:

[0014] A. Add hydrogenated castor oil into the reaction kettle, heat to 85-88°C until molten;

[0015] B. Keep the reaction temperature of 85-88°C, add rose essence, amide ester quaternary ammonium salt EAAQ, water-soluble lanolin, vitamin B5 to the obtained step A, melt, and stir evenly;

[0016] C, continue to maintain the reaction temperature of 85-88 ° C, then add activated carbon to the obtained step B and stir evenly;

[0017] D, stop heating, let cool to the mixture that step C gained solidifies;

[0018] E. Grind the obtained product in step D to 50-100 mesh, and pack it.

Embodiment 2

[0020] This hair dry-cleaning powder contains the following raw materials in parts by weight: 20 parts of activated carbon powder of 50-100 meshes, 3 parts of hydrogenated castor oil, 1 part of fruit essence, 0.06 part of amide ester quaternary ammonium salt EAAQ, and 2 parts of water-soluble lanolin , vitamin B50.5 parts.

[0021] The production method is as follows:

[0022] A. Add hydrogenated castor oil into the reaction kettle, heat to 85-88°C until molten;

[0023] B. Keep the reaction temperature of 85-88°C, add fruit flavor, amide ester quaternary ammonium salt EAAQ, water-soluble lanolin, vitamin B5 to the obtained step A, melt, and stir evenly;

[0024] C, continue to maintain the reaction temperature of 85-88 ° C, then add activated carbon to the obtained step B and stir evenly;

[0025] D, stop heating, let cool to the mixture that step C gained solidifies;

[0026] E. Grind the obtained product in step D to 50-100 mesh, and pack it.

[0027] When in use, spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com