In-situ steam explosion method and device

A steam explosion and in-situ technology, applied in chemical instruments and methods, methods of chemically changing substances by using atmospheric pressure, raw material pretreatment, etc., can solve the unsolved problems of entanglement and knotting of hemp fiber raw materials, and experimental analysis of resource waste , Hygienic level requirements and other issues, to achieve the effect of easy separation and combing process, quantitative and qualitative analysis, and simple recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

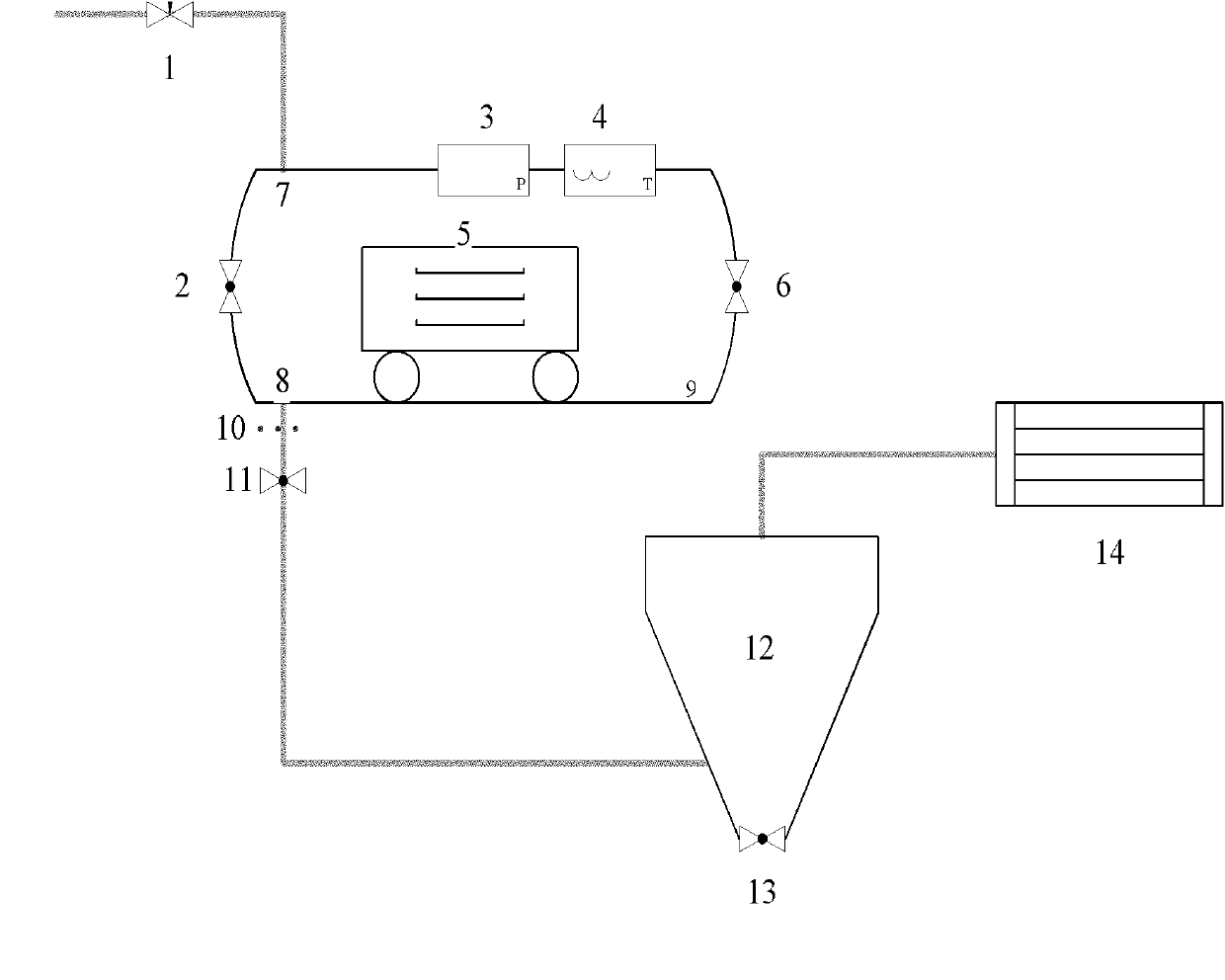

[0015] The volume of the pressure maintaining tank is 5L, the length is 28.5cm, and the side diameter is 15cm. The steam generator is 15L. The power of the steam generator has been turned on before feeding to obtain saturated water vapor at 220°C. The volume of the buffer tank is 20L, and the area of the coil heat exchanger is 0.1m 2 .

[0016] Take by weighing 200g of hemp bast fiber (average length is about 2m), soak it, after soaking for 1h, stack it in the box-type feeder 5, through the valve 2, push the feeder into the pressure maintenance tank 9, close the valve 1. Open the steam valve 1, feed a certain amount of steam, keep the pressure in the tank 9 at 0.7 MPa for 4 minutes, close the steam valve 1, quickly open the valve 11, the steam enters the pressure maintenance tank and then enters the condensation system 14, collects the condensed liquid, Open the discharge valve 6 again, drag out the cage feeder 5, and obtain the steam-exploded hemp fiber. Observe that the...

Embodiment 2

[0018] The volume of the pressure maintaining tank is 2L, the length is 25cm, and the side diameter is 10cm. The steam generator is 15L. The power of the steam generator has been turned on before feeding to obtain saturated water vapor at 220°C. The volume of the buffer tank is 15L, and the area of the coil heat exchanger is 0.05m 2 .

[0019] Cut the outdoor air-dried corn stalks into 1-2cm blocks (wherein the water content is 14%), weigh 100g (wet weight), add 32g of water to make the water content 35%, after the water is evenly absorbed, add to Inside the box-type feeding truck 5, the feeding truck is pushed into the pressure maintenance tank 9 through the valve 2, and the valve 1 is closed. Open the steam valve 1, feed a certain amount of steam, keep the pressure in the tank 9 at 1.2 MPa for 8 minutes, close the steam valve 1, quickly open the valve 11, the steam enters the pressure maintenance tank and then enters the condensation system 14, collects the condensed liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com