Single-side type anti-knotting compact chain vertical ring

A compact chain and vertical ring technology, applied in drag chains, hanging chains, conveyors, etc., can solve the problems of flat rings and vertical rings knotted, unusable, stuck chains, etc., and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below with reference to the accompanying drawings:

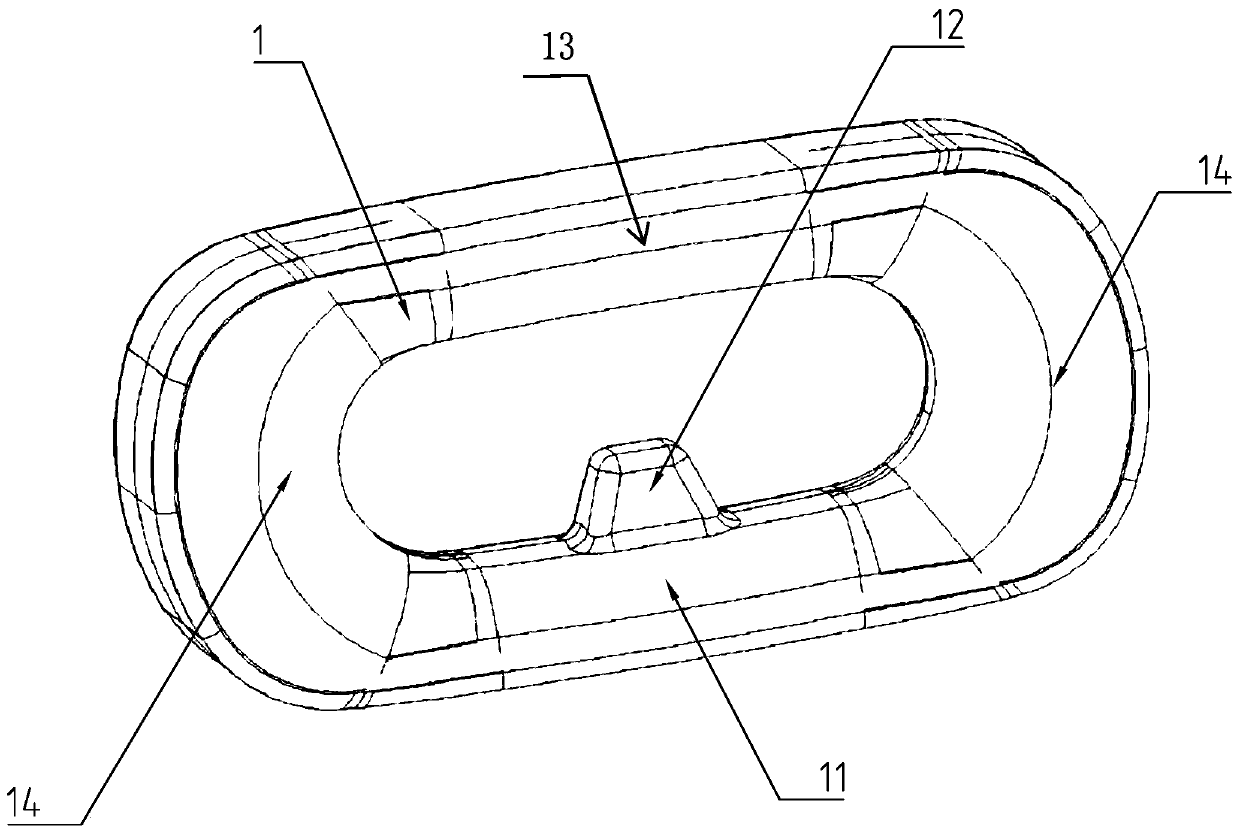

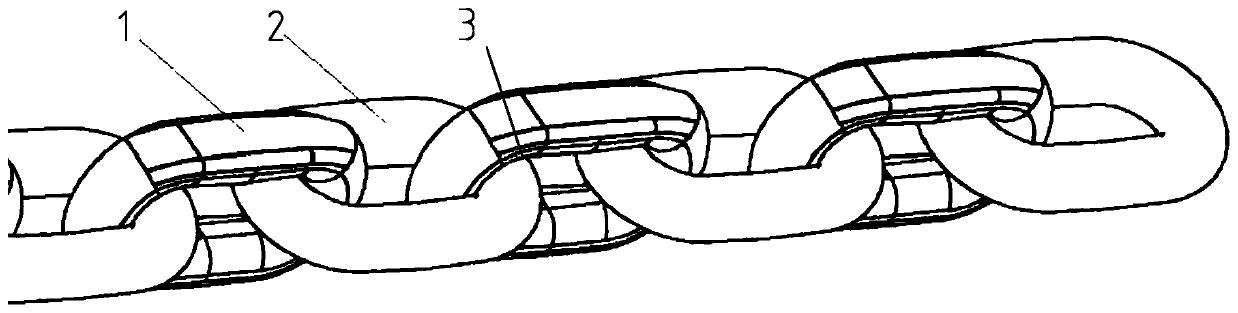

[0017] Such as Figure 1-Figure 6 As shown, this embodiment provides a one-sided anti-tangle compact chain stand ring, and a stopper 12 protruding inward is provided at the middle position of the first straight arm 11 of the stand ring 1 .

[0018] The vertical ring 1 is fitted with a flat ring 2, and the gap 3 between the stopper 12 and the second straight arm 13 on the other side of the vertical ring 1 is smaller than the diameter of the flat ring 2, which prevents the flat ring from 2 directions. The middle of the inner side of the vertical ring 1 moves, so that the flat ring 2 is always in the range of the small thickness of the vertical ring 1, ensuring the free rotation between the flat ring 2 and the vertical ring 1, thus solving the problem of knotting and jamming of the compact chain question.

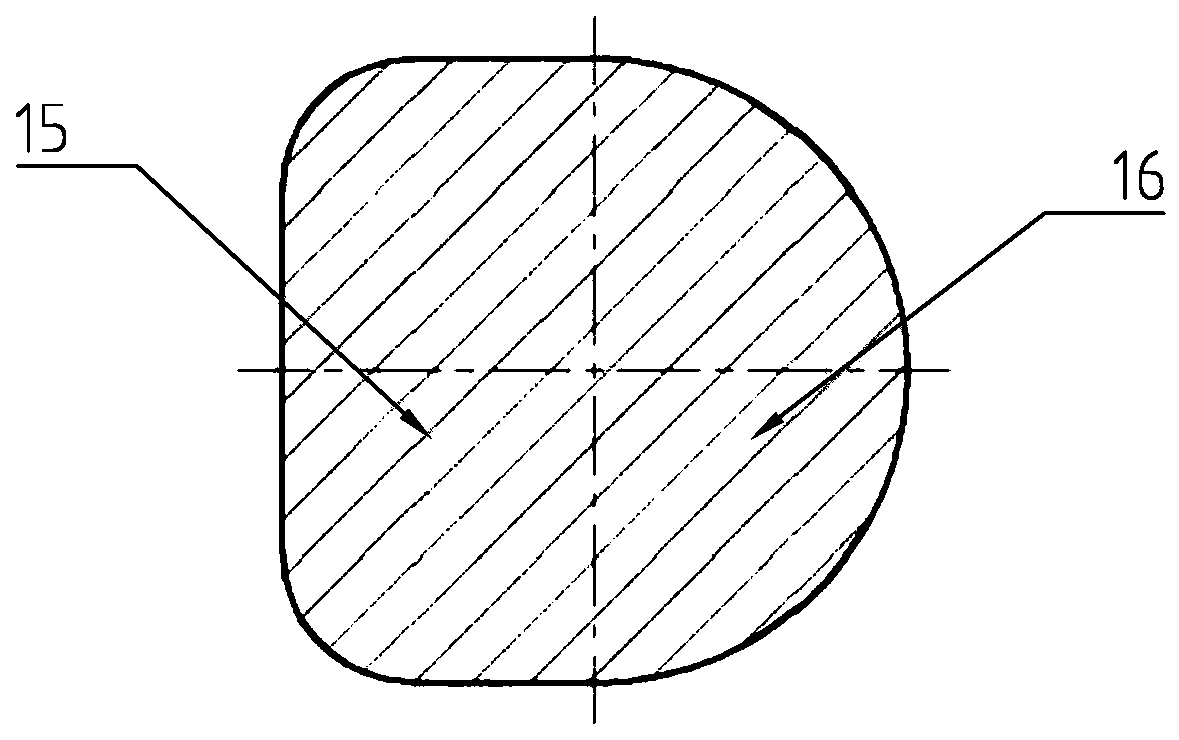

[0019] In order to improve the mechanical properti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com