Non-assembled guardrail

An assembly-free, guardrail technology is applied in the field of children's guardrails, which can solve the problems of poor folding effect of folding guardrails, and achieve the effects of volume reduction, easy folding and folding, and elimination of assembly problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

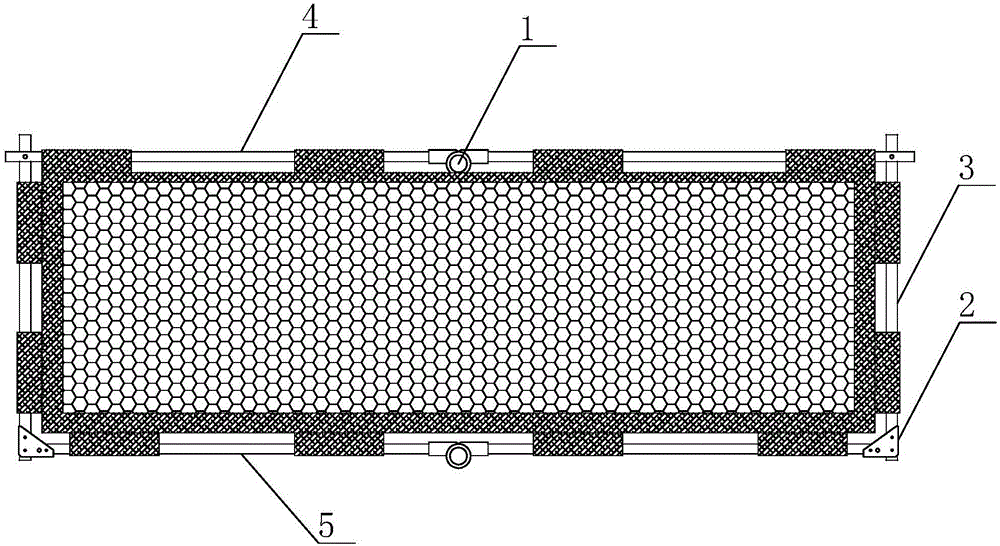

[0045] Embodiment 1: The present invention is an assembly-free guardrail. The main structure includes a quadrangular frame and a protective net installed on the frame. Rod 4, and the lower cross bar 5 arranged on the bottom side, the upper cross bar 4 and the lower cross bar 5 are both centered with the first hinge 1 and can be carried out on the plane where the frame is located through the first hinge 1 Folding, and the upper cross bar 4 is folded downward, and the lower cross bar 5 is folded upward, and the body is very small after being folded. The first hinge 1 includes a female rotating base 6, a sub rotating base 7, a limit clip 8, a top piece 9 and a first spring 10, and a first connecting sleeve 11 is provided on the side wall of the female rotating base 6 , the first connecting sleeve 11 is fixedly connected with the upper cross bar 4 or the lower cross bar 5, and the second connecting sleeve 12 is provided on the sub-rotating base 7, and the second connecting sleeve ...

Embodiment 2

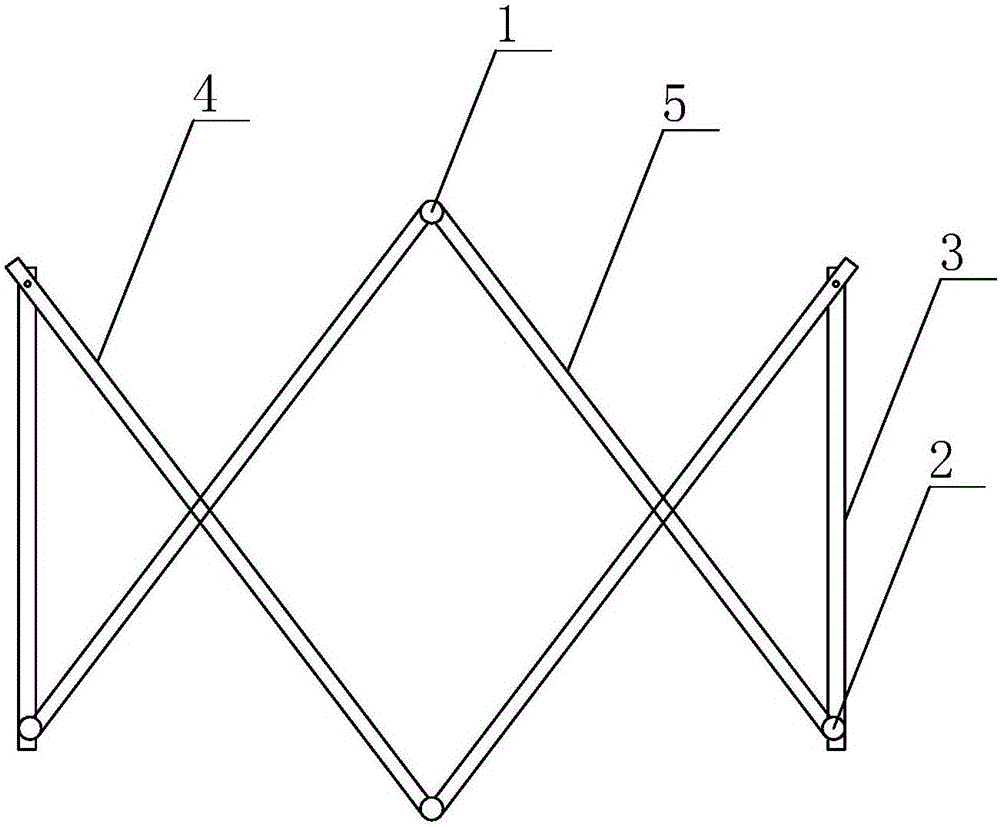

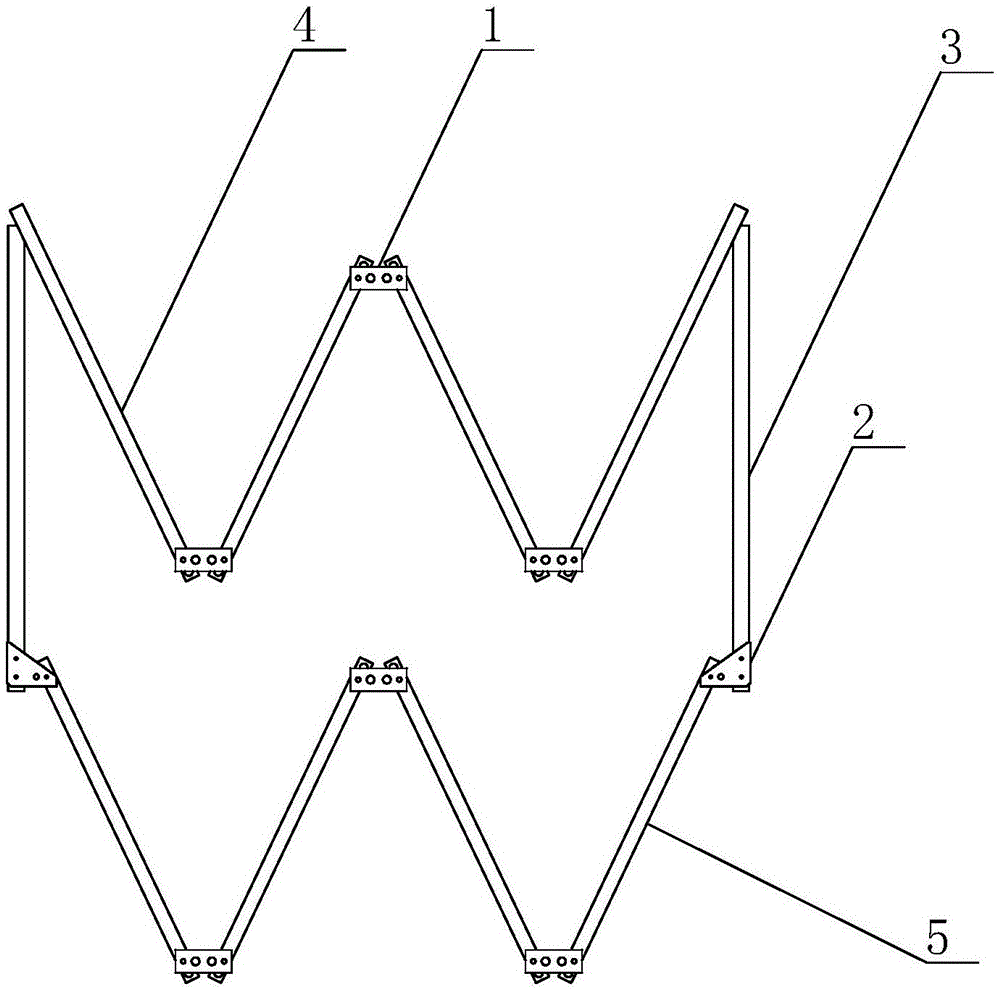

[0046]Embodiment 2: The present invention is an assembly-free guardrail. The main structure includes a rectangular frame and a protective net installed on the frame. The rod 4, and the lower cross bar 5 arranged on the bottom side, the upper cross bar 4 and the lower cross bar 5 are equidistantly provided with three first hinges 1 and can pass through the first hinges 1 on the plane where the frame is located Folding in a "W" shape, the first hinge 1 includes two opposite rectangular plates 28, and the upper cross bar 4 and the lower cross bar 5 are connected between the two rectangular plates 28, The left half of the rectangular plate 28 is fixed to the adjacent upper / lower cross bar 5 by threaded pins, and the right half of the rectangular plate 28 is hinged to the adjacent upper / lower cross bar 5 through a pivot pin. And the upper / lower cross bar 5 is provided with a spring pin, the spring pin includes a pin tube 32, a second spring 33, and a T-shaped pin 34, and the pin tu...

Embodiment 3

[0047] Embodiment 3: The present invention is an assembly-free guardrail. The main structure includes a rectangular frame and a protective net installed on the frame. Rod 4, and the lower cross bar 5 arranged on the bottom side, the upper cross bar 4 and the lower cross bar 5 are both centered with the first hinge 1 and can be carried out on the plane where the frame is located through the first hinge 1 Folding, and the upper cross bar 4 and the lower cross bar 5 are folded in the same direction, and the body is very small after being folded. The first hinge 1 includes a female rotating base 6, a sub rotating base 7, a limit clip 8, a top piece 9 and a first spring 10, and a first connecting sleeve 11 is provided on the side wall of the female rotating base 6 , the first connecting sleeve 11 is fixedly connected with the upper cross bar 4 or the lower cross bar 5, and the second connecting sleeve 12 is provided on the sub-rotating base 7, and the second connecting sleeve 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com