Portable and adjustable large tonnage cable laying device

A cable laying and adjustable technology, used in cable laying equipment, transportation and packaging, thin material handling, etc. The effect of strong overall load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

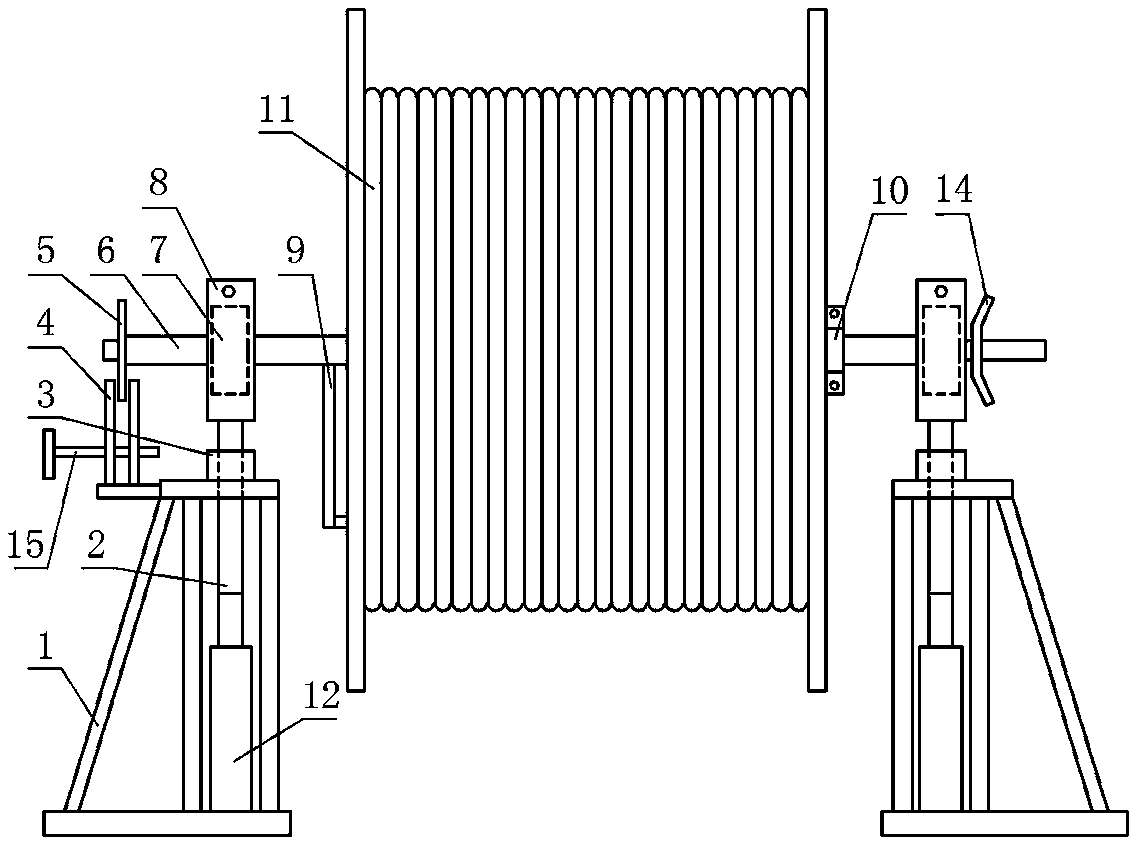

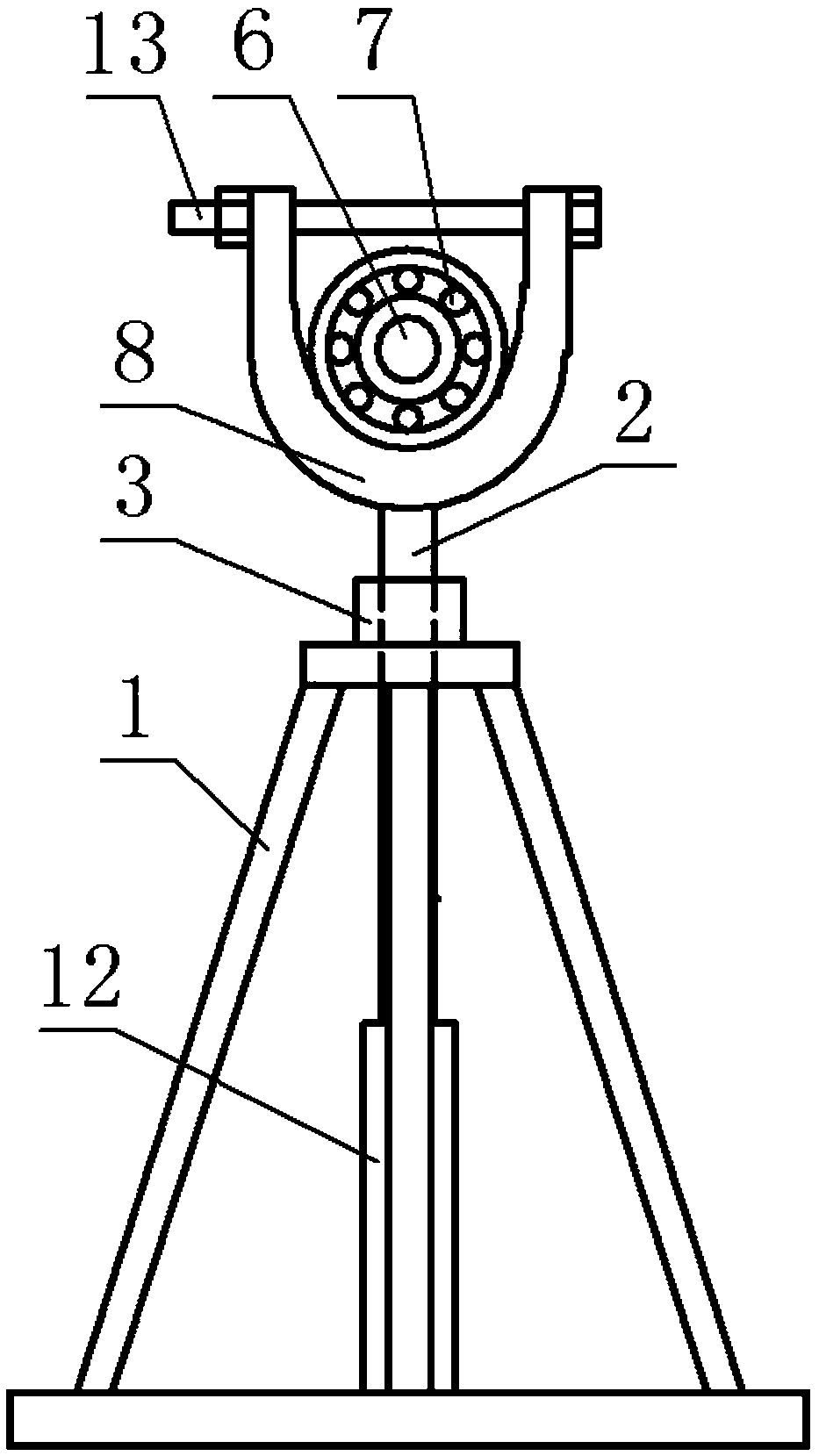

[0020] Example: see Figure 1-Figure 2 , in the picture, 1-side bracket, 2-lift rod, 3-guide sleeve, 4-brake pad, 5-brake wheel, 6-shaft, 7-bearing, 8-bearing bracket, 9-toggle lever, 10-positioning hoop, 11-cable reel, 12-hydraulic cylinder, 13-limit bolt, 14-rotary plug, 15-screw crank arm.

[0021] The portable and adjustable large-tonnage cable laying device includes two side supports 1, a shaft 6 is arranged on the upper end of the two side supports 1, and a cable reel 11 is arranged on the shaft 6, wherein: the upper end of each side support 1 is A guide sleeve 3 is provided, and a lifting rod 2 is set in the guiding sleeve 3, and the two are slidably matched. The lower end of the lifting rod 2 is connected with the piston rod of the hydraulic cylinder 12, and the upper end of the lifting rod 2 is connected with the lower end of the bearing bracket 8. The shaft rod 6 is provided with two bearings 7, and the two bearings 7 are respectively placed in the upper end grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com