Method and system for laser cutting through dynamic following of synchronous passing plates

A laser cutting and laser cutting head technology, applied in laser welding equipment, welding/cutting auxiliary equipment, welding equipment, etc., can solve the problems of lower production efficiency, automatic removal of difficult-to-shape waste, and stable knife breaking in difficult-to-cut processes, etc., to achieve The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

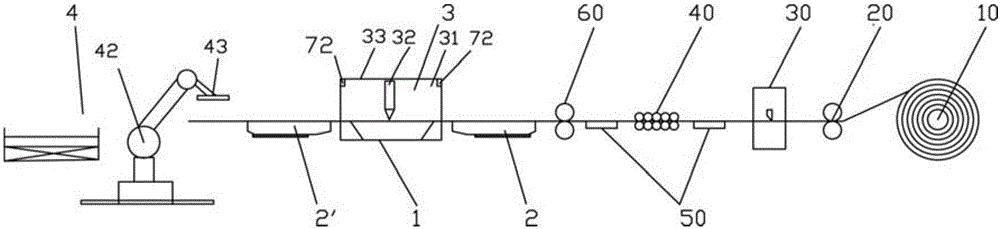

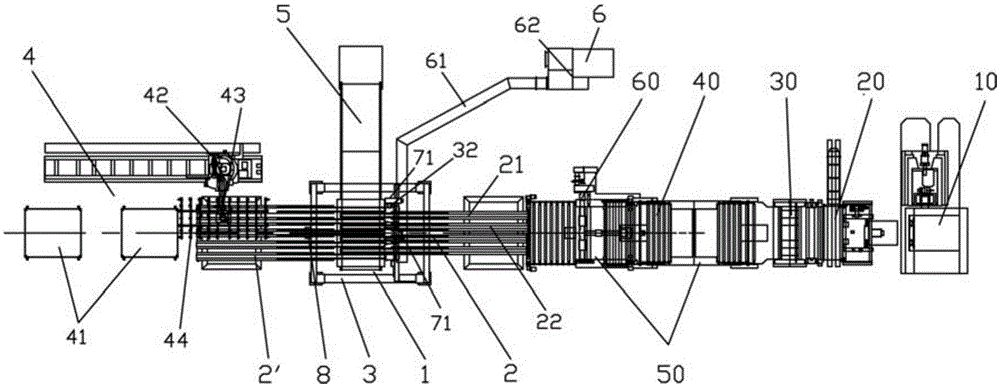

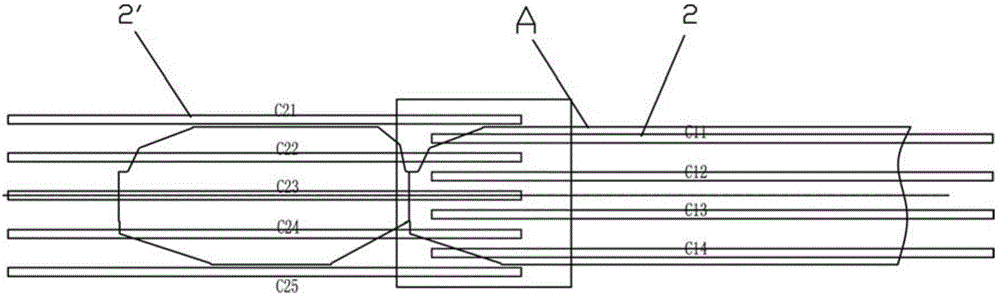

[0034] see figure 1 , figure 2 , the system of synchronous plate-passing dynamic follow laser cutting of the present invention, it comprises: a processing position 1; On the material side, each magnetic belt C11, C12, C13, C14, C21, C22, C23, C24, C25 in the magnetic belt group can be extended or retracted, and the gap between each magnetic belt can be adjusted;

[0035] The laser cutting unit 3 is arranged on the processing position 1, and it includes at least one laser cutting machine 31 and an upper laser cutting head 32;

[0036] The handling and stacking unit 4 includes a stacking platform 41 and a handling and stacking robot 42 (end picker 43 and its vacuum chuck 44), and the stacking platform 41 is arranged on the synchronous pass-through unit 2' on the discharge side of the processing position 1 Magnetic belt set outside;

[0037] The waste conveyor belt device 5 is arranged on the side perpendicular to the feeding direction of the processing position 1;

[0038] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com