Camera inspection device for empty glass bottles

A technology for inspection devices and empty bottles, applied in the direction of conveyor control devices, packaging, packaging bottles, etc., can solve problems such as equipment failure, glass empty bottle conveyor belt drop, blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below through specific embodiments in conjunction with the accompanying drawings. The upper, lower, left, and right mentioned in the present invention are all based on the accompanying drawings.

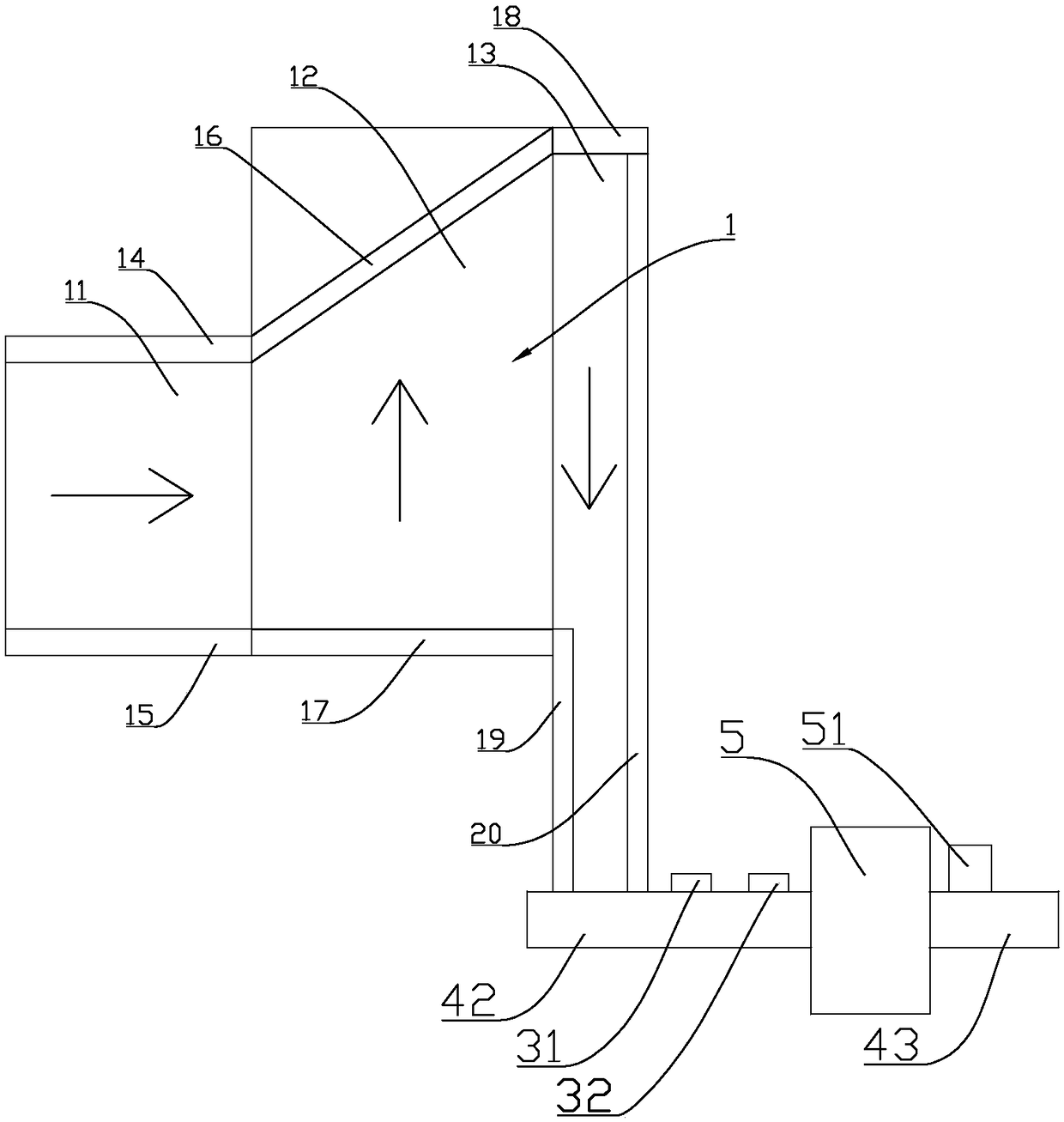

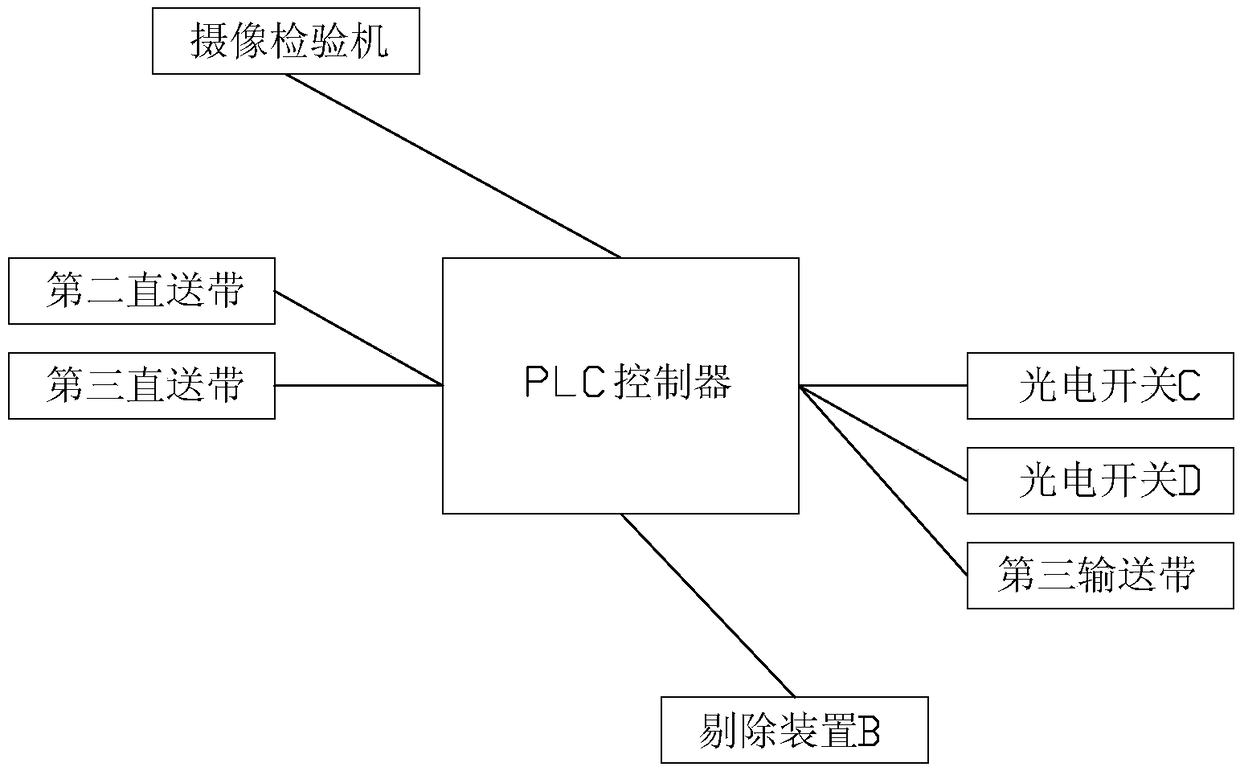

[0018] like figure 1 , 2 The shown camera inspection device for empty glass bottles includes a feeding device 1 and a camera inspection machine 5 arranged in sequence, and the empty glass bottles output by the feeding device 1 are sent into the camera inspection machine through a second direct feeding belt 42 5. Then the empty glass bottles are output from the camera inspection machine 5 through the third straight-feeding belt 43, the side of the second straight-feeding belt 42 is provided with a photoelectric switch D31 and a photoelectric switch C32 sequentially from front to back, and the third direct-feeding The side of the band 43 is provided with a rejecting device B51, and the camera inspection machine 5, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com