Automatic gear clearance elimination mechanism

An automatic and anti-backlash technology, applied in the direction of belts/chains/gears, mechanical equipment, components with teeth, etc., can solve problems such as adjustment difficulties, space and structure restrictions, and achieve stable and reliable work and convenient installation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

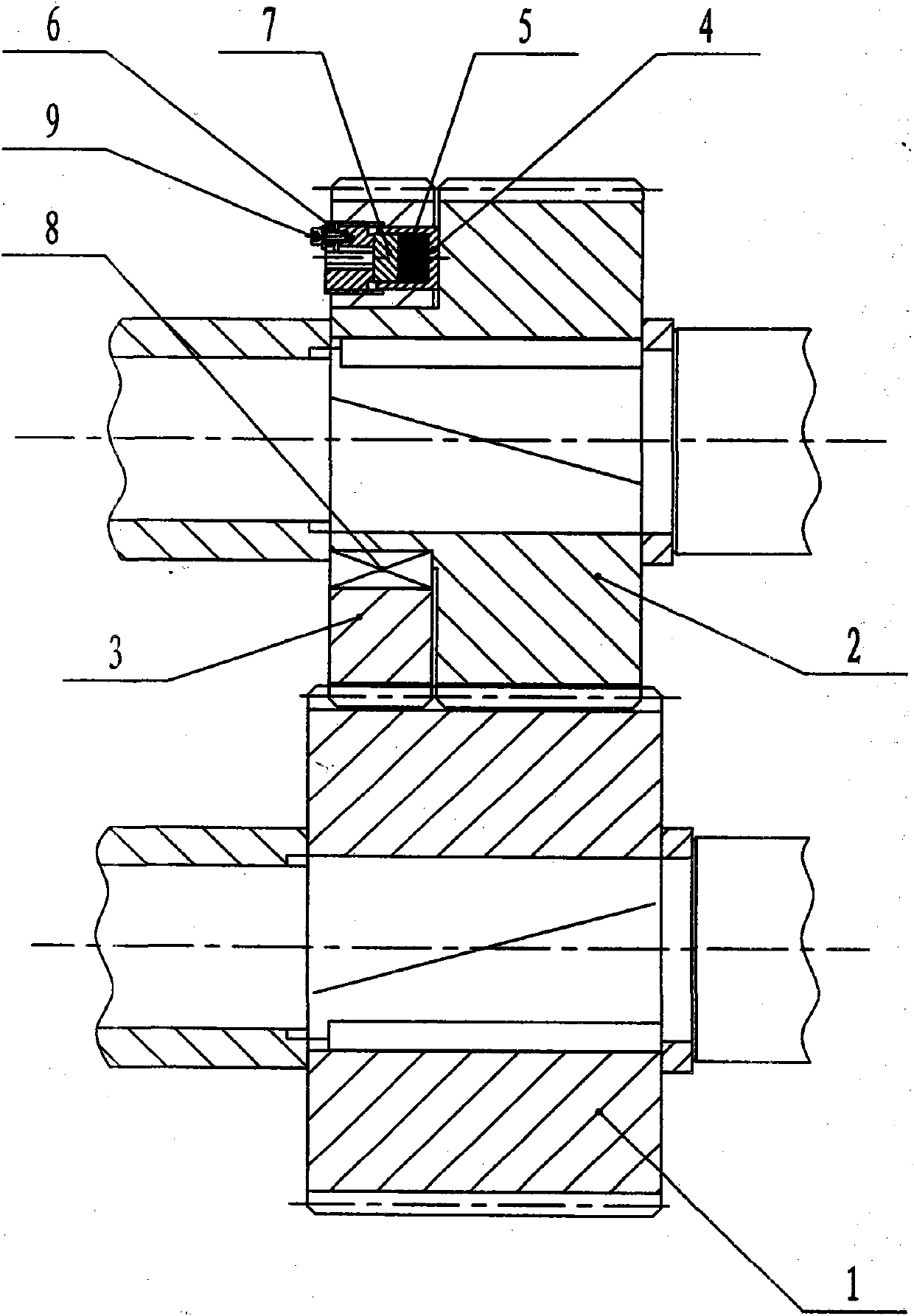

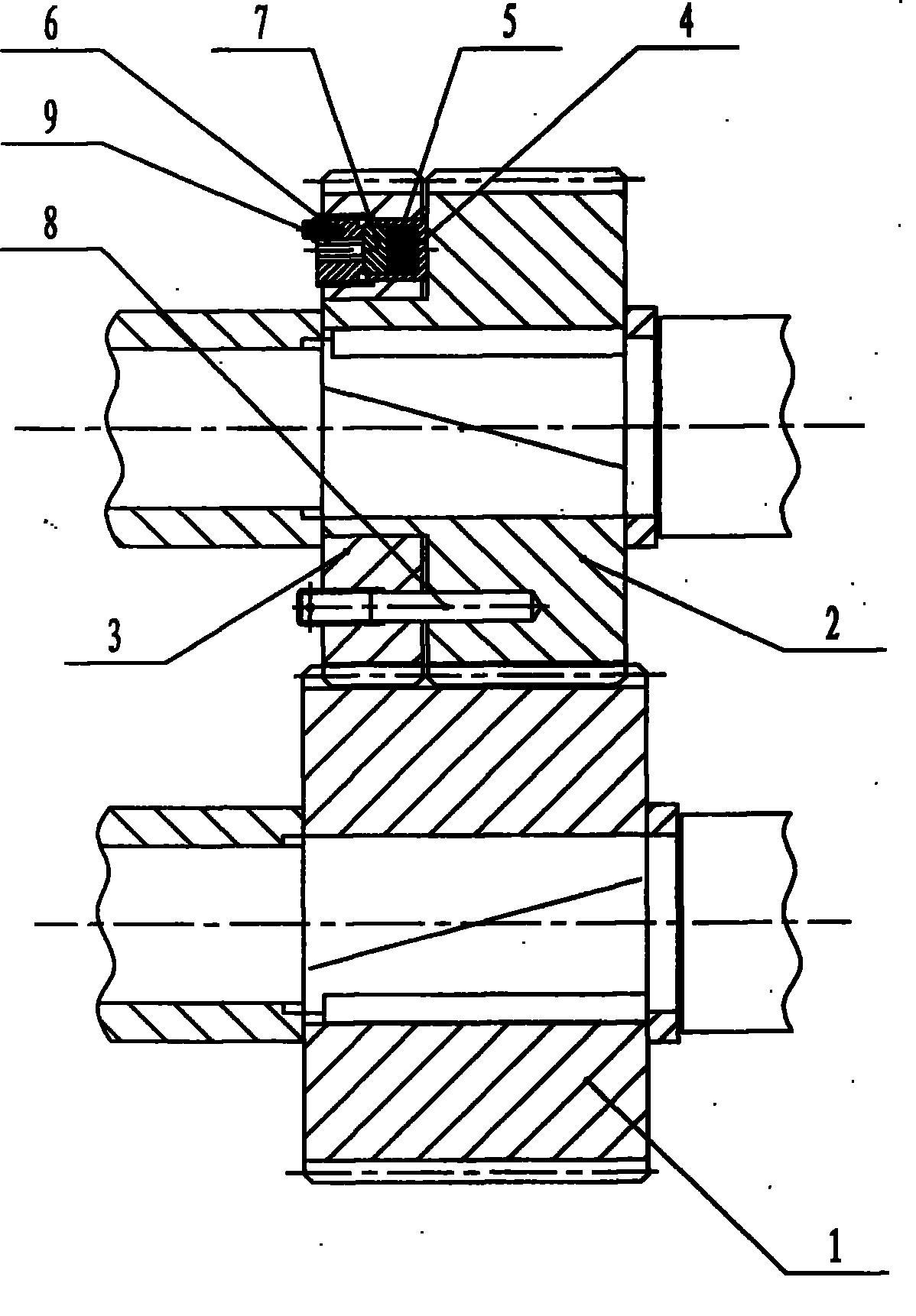

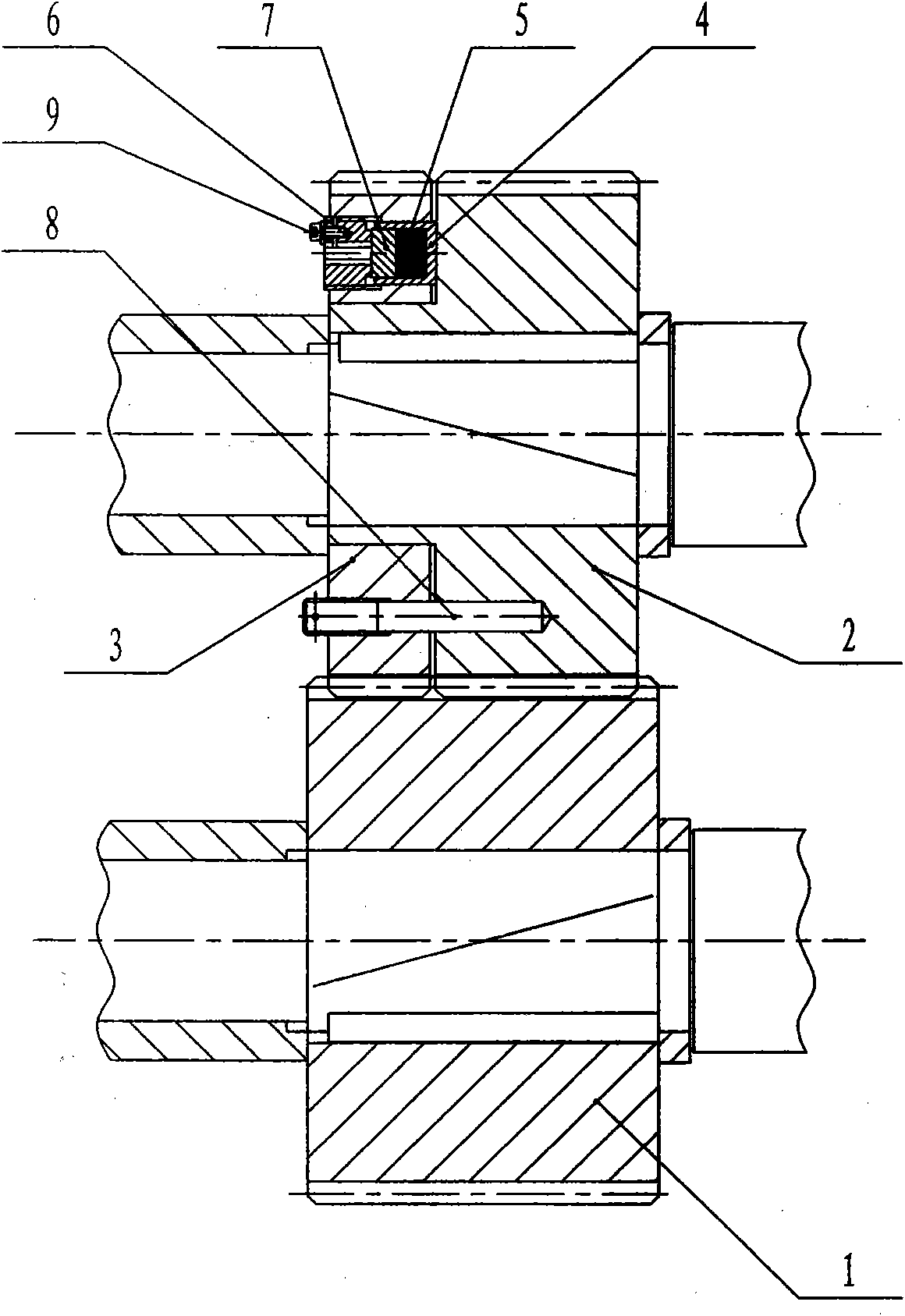

[0015] Such as figure 1 , figure 2 As shown, the present invention is mainly made up of transmission gear 1, fixed gear 2, moving gear 3, guide sleeve 4, spring 5, lock nut 6, pressure ring 7, connector 8 and screw 9 etc. The transmission gear 1 and the fixed gear 2 are helical gears, which mesh with each other, and are connected to the transmission shaft with a key to realize the master and slave transmission; the moving gear 3 is a helical gear, which is fixed on the fixed gear 2 through the connecting piece 8, and the connecting piece 8 is Key or pin, guide sleeve 4 is installed in the end face hole of moving gear 3, spring 5 is installed in the hole of guide sleeve 4, lock nut 6 compresses spring 5 through pressure ring 7, spring 5 is a disc spring, screw 9 prevents locking The tight nut 6 is loose.

[0016] Transmission gear 1, fixed gear 2, and moving gear 3 are carburized and quenched with 20CrMoTi, the carburized layer depth is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com