Automatic assembly method of decorative light production line

An automatic assembly and production line technology, applied in the field of machinery, can solve problems such as increased useless workload, time-consuming production, and decreased accuracy, and achieve the effects of improving production efficiency, reducing production costs, and ensuring the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

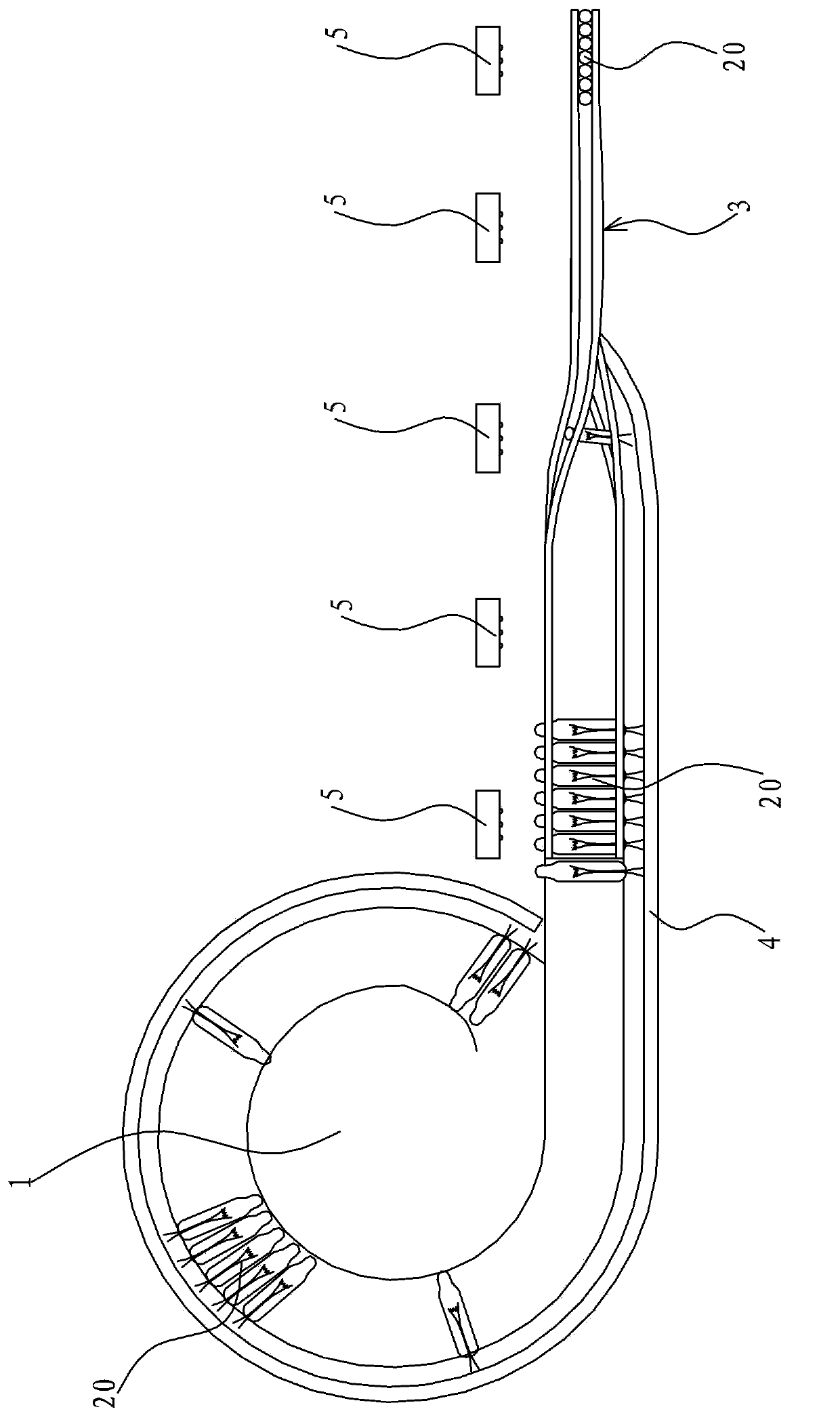

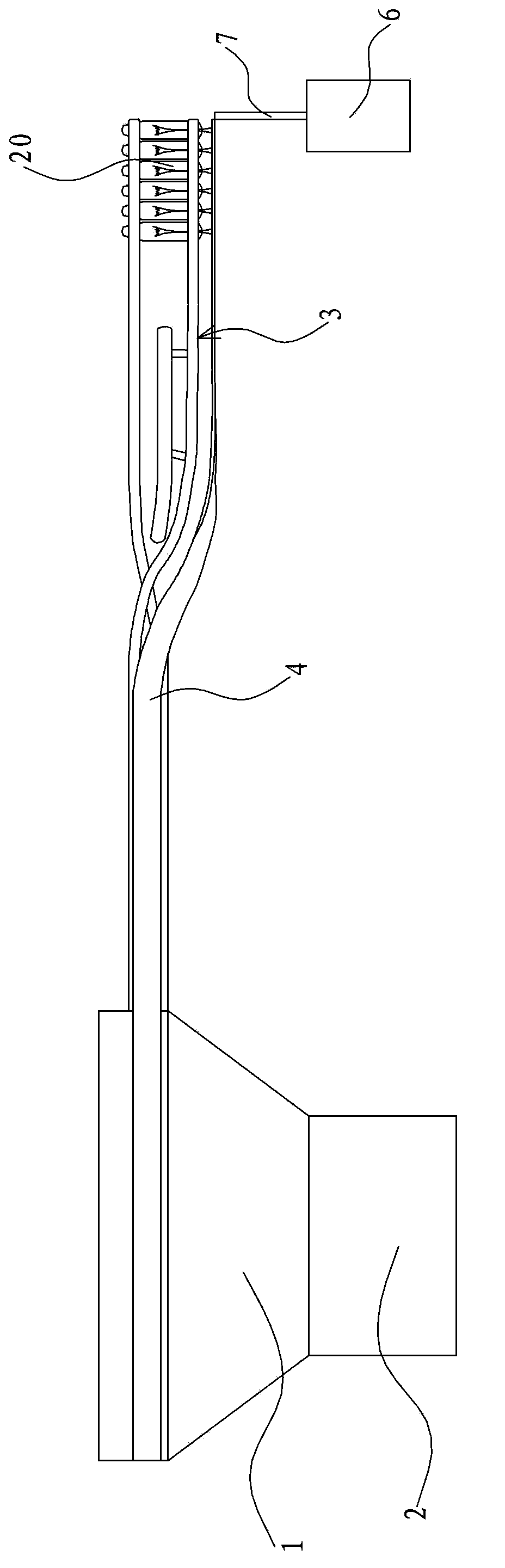

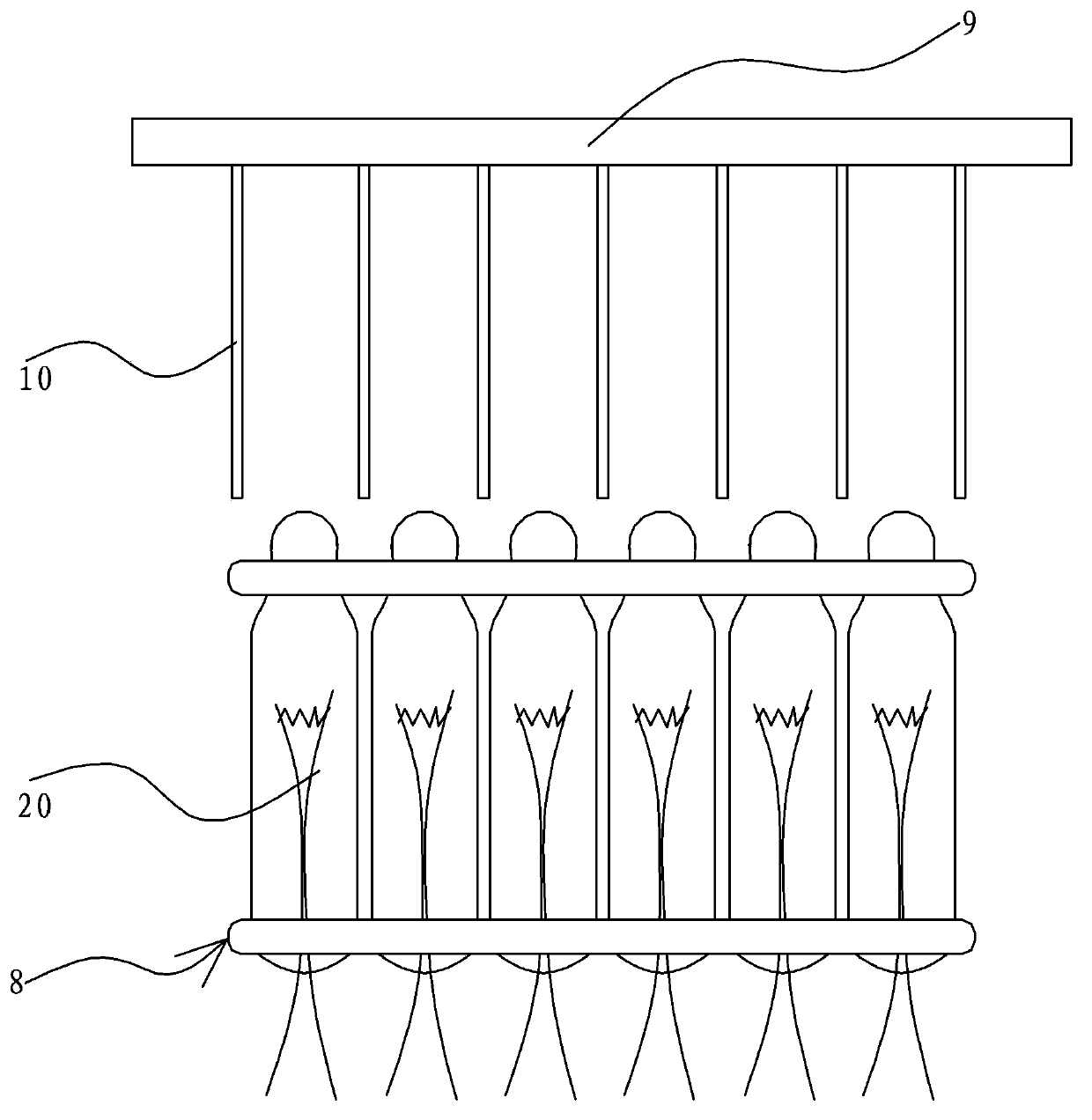

[0038] Such as Figure 1 to Figure 9 As shown in , the automatic assembly device of this decorative lamp production line includes a shaking tray 1, a vibrator 2, a feeding track 3, a conveying track 8, a batching track 16, a positioning mechanism, a wire clamping mechanism, a branching mechanism, a testing mechanism, Discharging mechanism, seating mechanism and wire folding mechanism, etc.

[0039] The bottom of the shaking tray 1 has a disc-shaped collecting cavity, and has an upward feeding opening, and is provided with a circle that connects the collecting cavity and gradually rises around the arc. The side edge extends horizontally to form a discharge port, and the discharge port connects with the feed port of the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com