Automatic assembling machine for automobile cigar lighter

A technology for automatic assembly machines and car cigarette lighters, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., and can solve the problems of low manual assembly efficiency, poor quality of finished products, and lack of detection functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

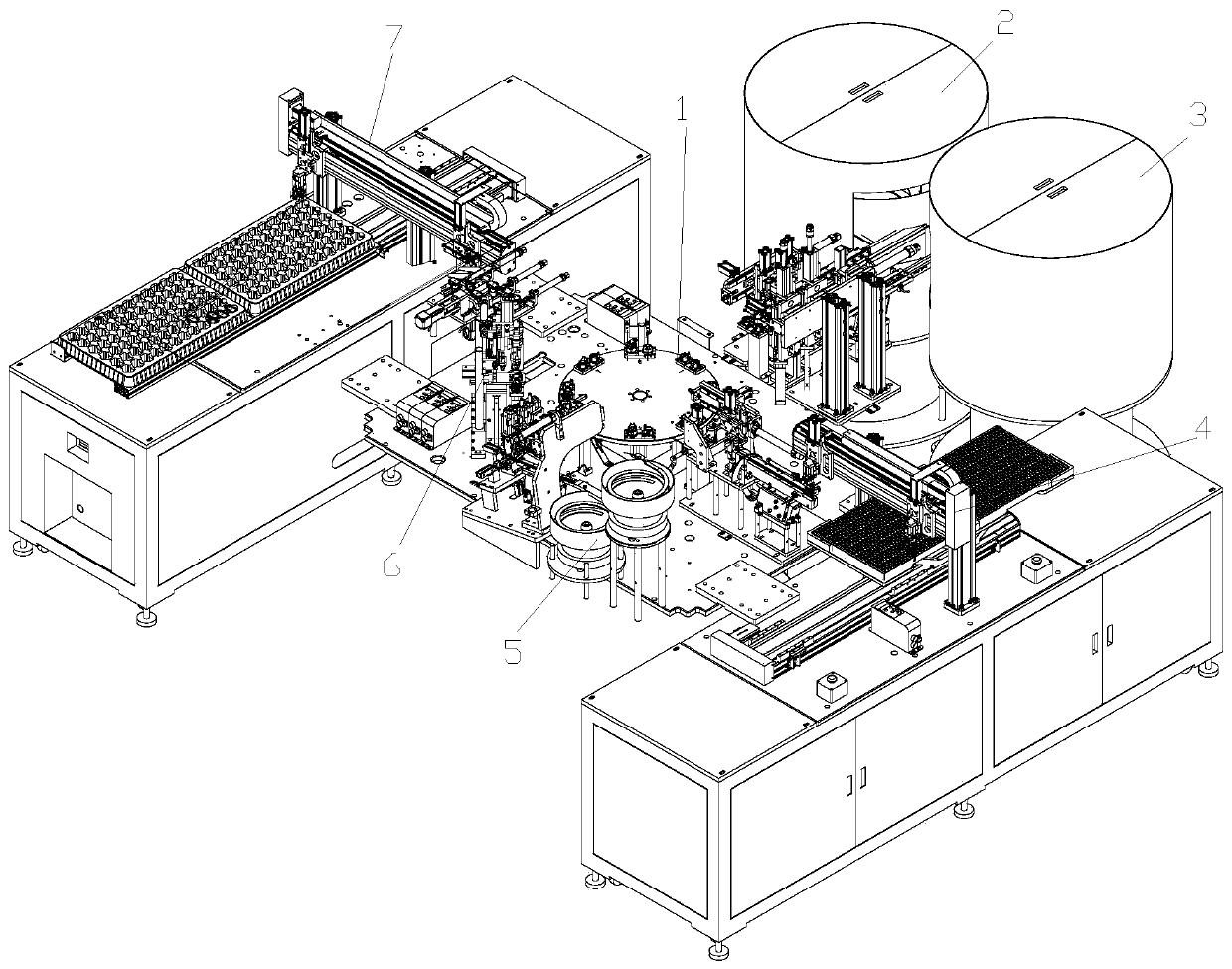

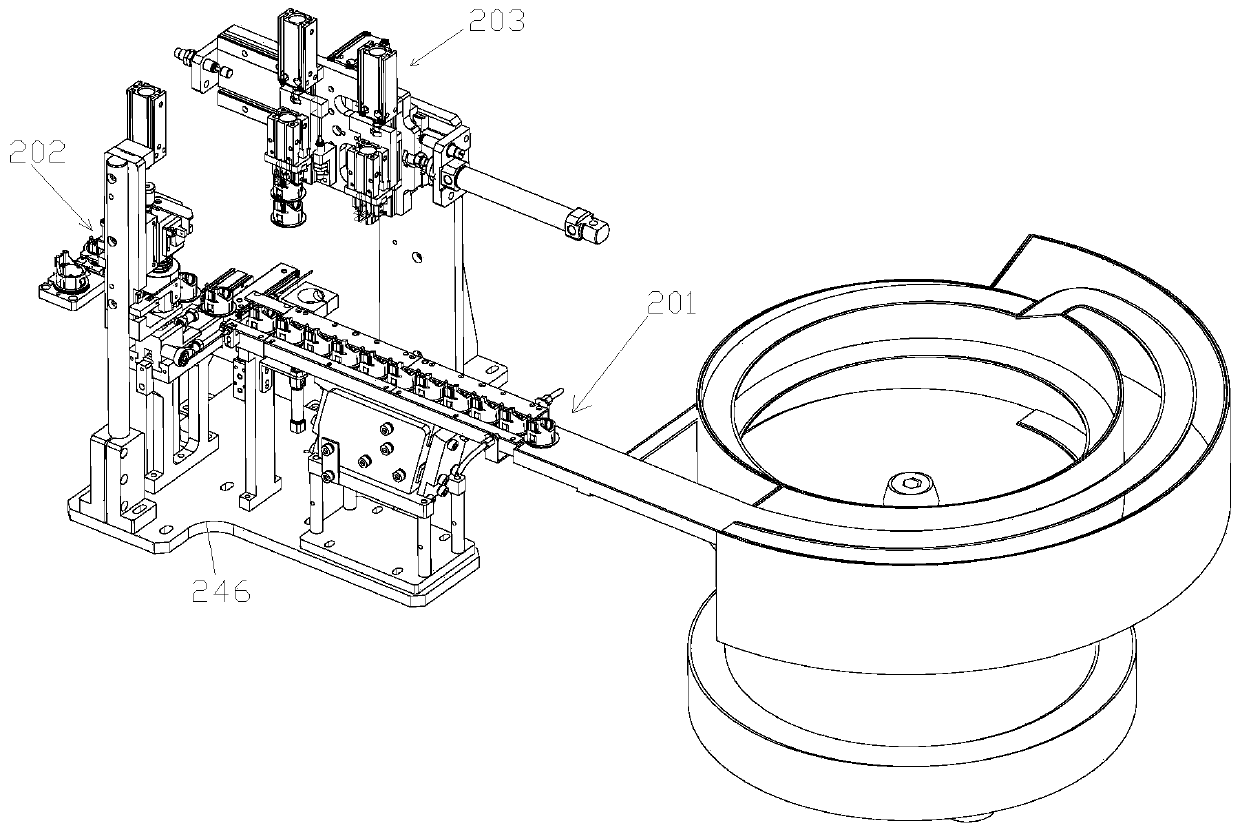

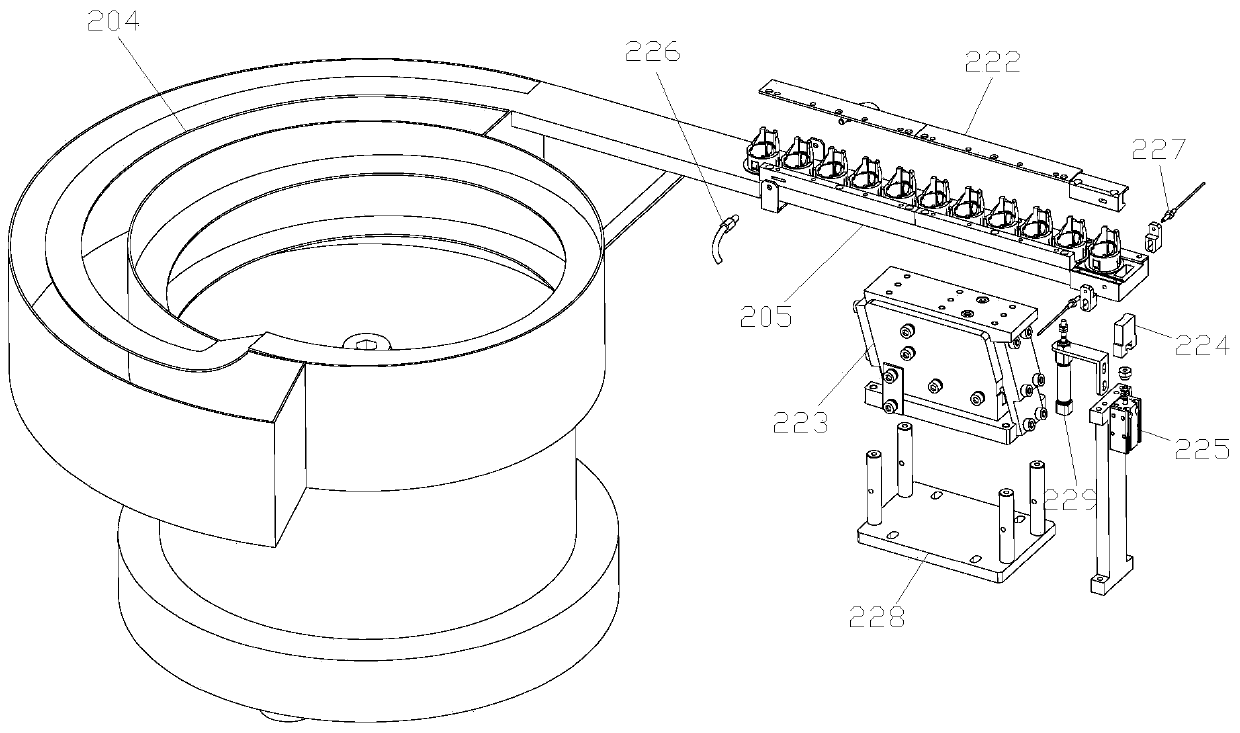

[0050] Attached below Figure 1-32 This embodiment is described in detail. This embodiment provides an automatic assembly machine for a car cigarette lighter, which includes turntable jigs 1 distributed in a circular array. The turntable jigs 1 are placed on the electric turntable and completed during the rotation process Conversion of assembly parts at each station. The outside of the turntable fixture 1 is surrounded by a clamping sleeve assembly mechanism 2, a clamping ring assembly mechanism 3, a clamping cover assembly mechanism 4, a torsion spring and shaft assembly mechanism 5, an overall assembly mechanism 6, and a finished product unloading mechanism 7. The clamping sleeve assembly mechanism 2 includes a clamping sleeve feeding device 201, a clamping sleeve detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com