Automatic bullet loading system based on friction conveying and screw conveying

An automatic loading system and spiral conveying technology, applied in the direction of ammunition supply, weapon accessories, offensive equipment, etc., can solve the problems of high labor intensity, low efficiency, slow speed, etc., and achieve the effect of convenient repair and maintenance, and convenient installation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the drawings and implementation process.

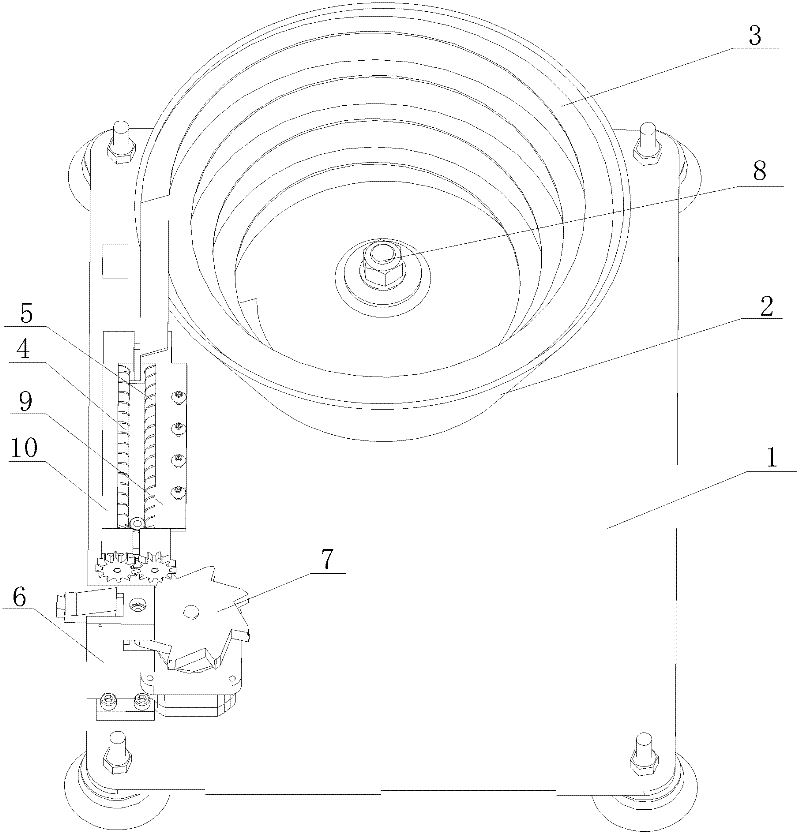

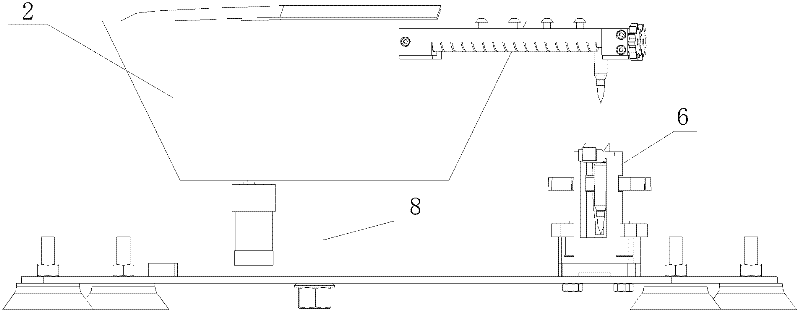

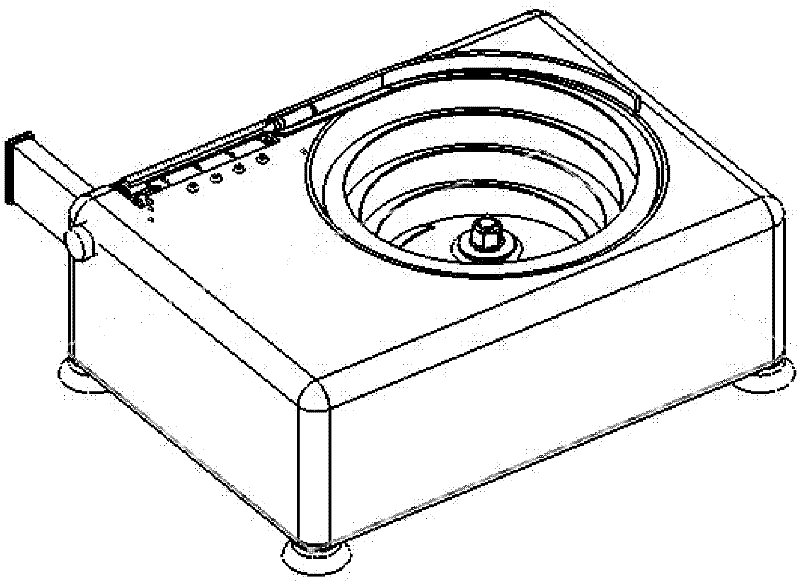

[0031] Such as figure 1 , figure 2 As shown, the bullet automatic loading system based on friction transmission and screw transmission of the present invention includes a base 1, a drum 2, a screw conveyor belt 3, a screw rod 4, a screw rod 5, a magazine joint seat 6, a push mechanism 7, Column 8, right screw rod support 9, left screw rod support 10, drum motor and screw rod motor.

[0032] Such as figure 1 As shown, the base 1 is fixed with a column 8, the column 8 is located on the rotating shaft of the drum 2, the drum 2 rotates around the column 8, the screw conveyor belt 3 is fixedly connected with the base 1, and is arranged close to the inner wall of the drum 2, and the screw conveyor belt 3 There is a gap of 1 mm between the inner wall of the drum 2, and the input end of the screw conveyor belt 3 is located at the bottom of the drum 2. The dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com