Full-automatic 1/2 quick-connect assembly assembling machine tool

A fully automatic, machine tool technology, applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve problems such as wrong assembly of parts, unqualified products, and unguaranteed product quality, and achieve high assembly efficiency and fewer operators , The effect of reducing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

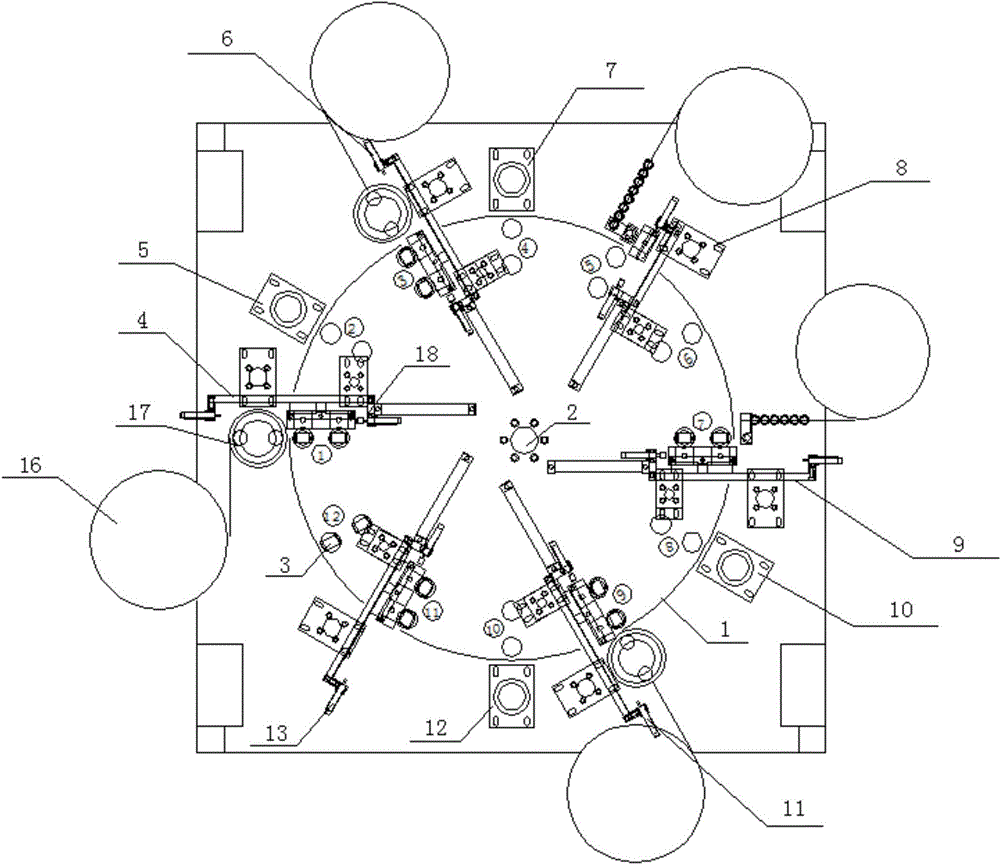

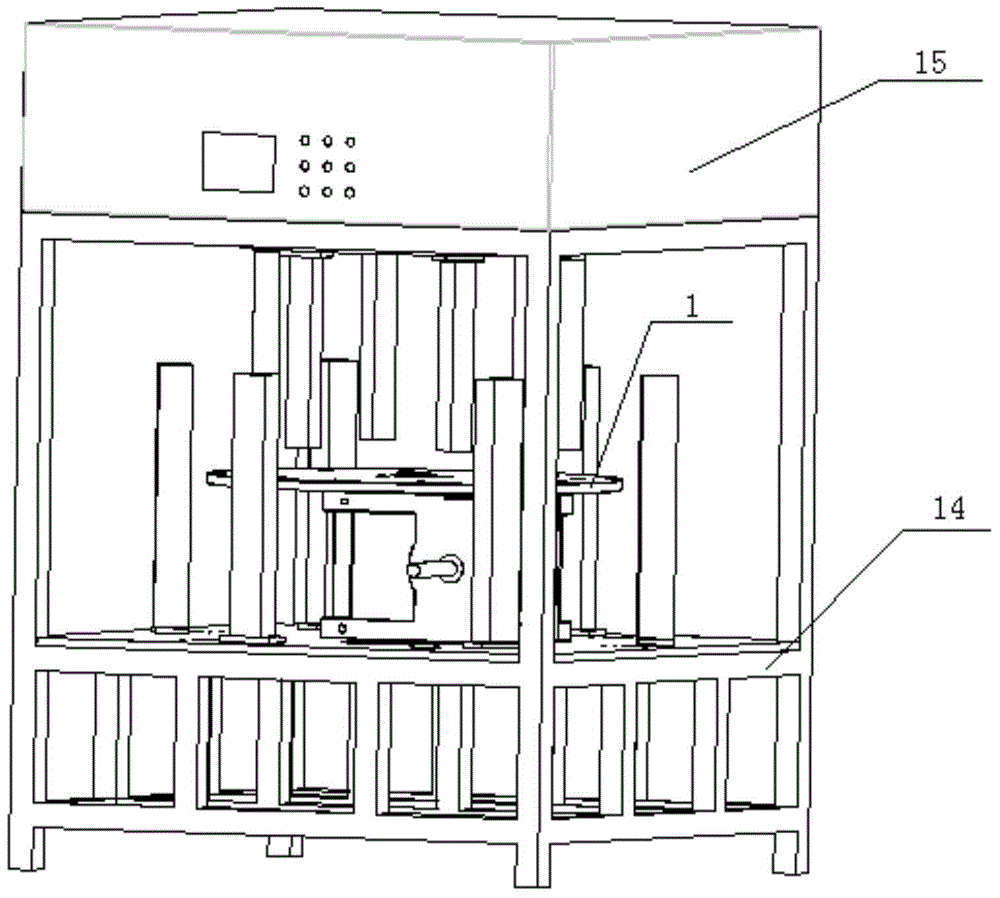

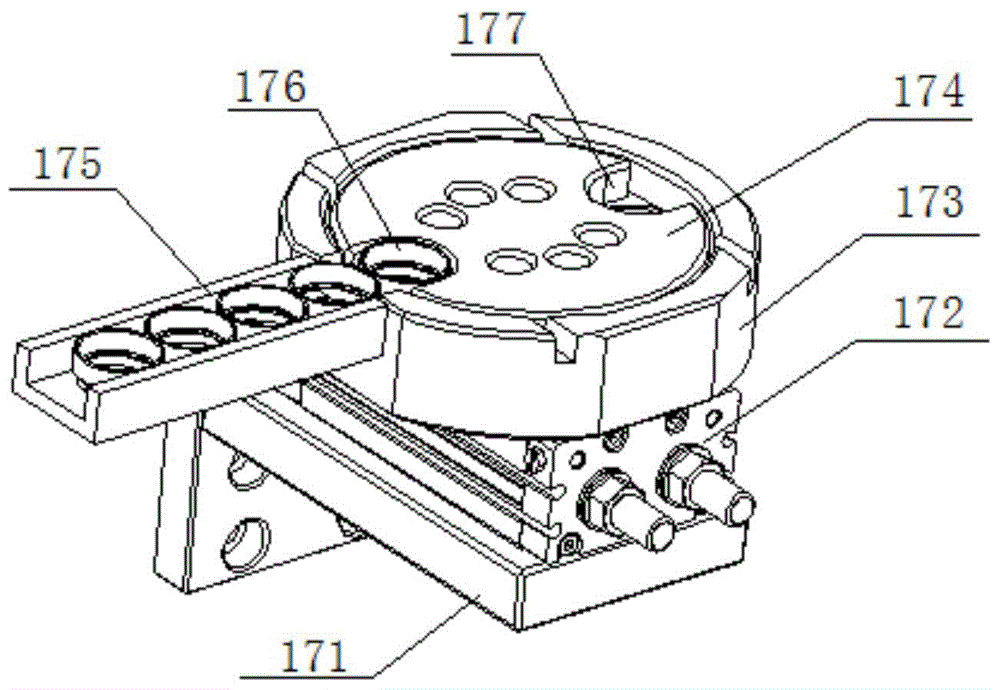

[0019] Such as figure 1 As shown, the fully automatic 1 / 2 quick-connect component assembly machine tool includes a circular worktable 1, a transmission device 2 and a driving device. Twelve groups of product positioning fixtures 3 are arranged on the circular worktable 1 along the circumference, and each group The positioning fixture 3 includes 2 sets of identical positioning fixtures; the positions of the positioning fixtures 3 around the outer side of the circular workbench 1 are sequentially provided with a plastic cover loading device 4, a plastic cover pressing device 5, and a plastic sleeve loading device 6, Plastic sleeve press-fitting device 7, clip reed loading device one 8, clip reed loading device two 9, clip reed pressing device 10, plastic gasket loading device 11, plastic gasket pressing device 12, Finished product blanking device 13; figure 1 , figure 2 As shown, the transmission device 2 is a cam intermittent splitter with 12 equal parts, the circular workta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com