O-shaped ring assembling equipment

A technology for assembly equipment and O-rings, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as easy to leak assembly, low assembly efficiency, and high production of finished products, so as to improve the yield of finished products and reduce Production cost, effect of avoiding product damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

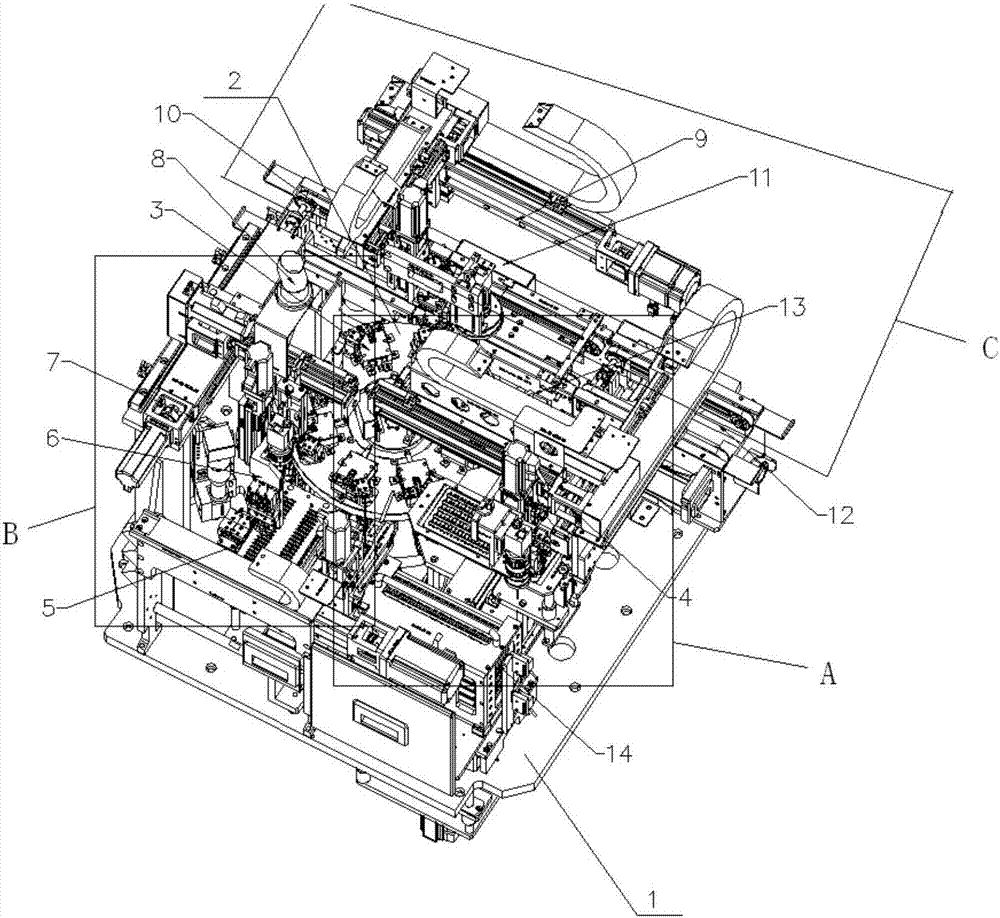

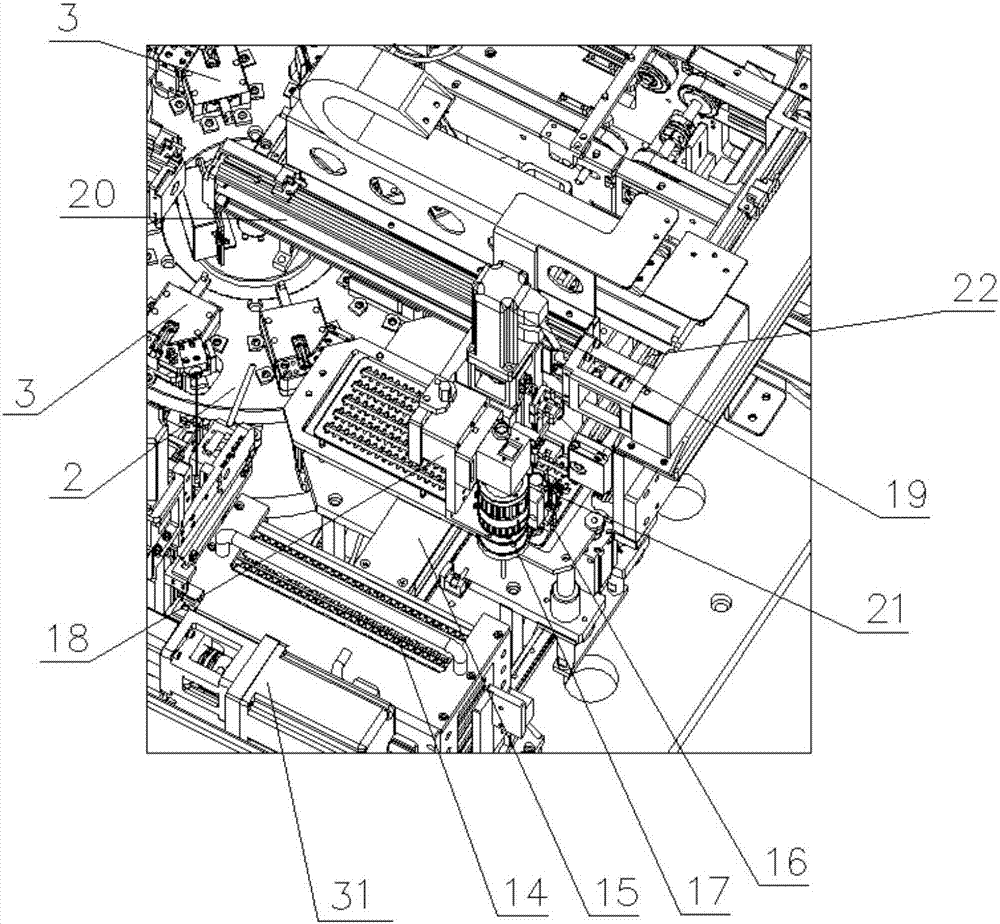

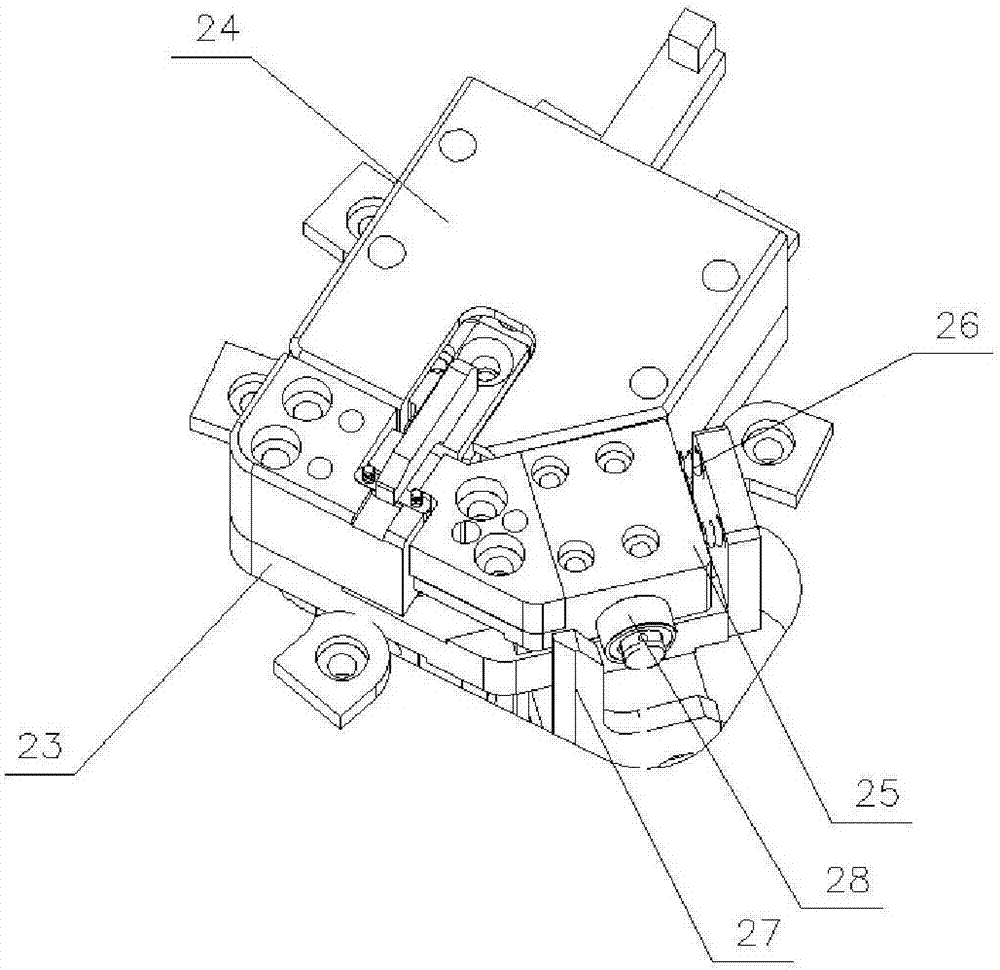

[0020]Embodiment: An O-ring assembly equipment, including a workbench 1, a turntable 2, a turntable drive device, a product positioning carrier 3, a button tray placement area, a button feeding module 4, an O-ring Mylar positioning device 5, O-ring picking and assembly mechanism 6, horizontal detection mechanism 7, vertical detection mechanism 8, unloading module 9, empty tray conveying mechanism 10, empty tray positioning mechanism 11, finished product conveying mechanism 12, waste recycling box 13 and controller , the turntable 2 can be rotated around the vertical axis and positioned on the workbench 1, a number of product positioning carriers 3 are fixedly installed on the surface of the turntable 2, the product positioning carriers 3 can fix and position button products, and the button tray placement area is used for placing The button tray with the O-ring to be assembled is installed, the button feeding module 4 can place the buttons in the tray on the button tray placemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com