Shaping and assembling equipment of junction boxes

A technology for assembling equipment and junction boxes, which is applied in the direction of mechanical equipment, connecting components, and devices for coating liquid on the surface, etc. It can solve problems such as increased production costs, low automation, and errors, so as to improve work efficiency and save manpower cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

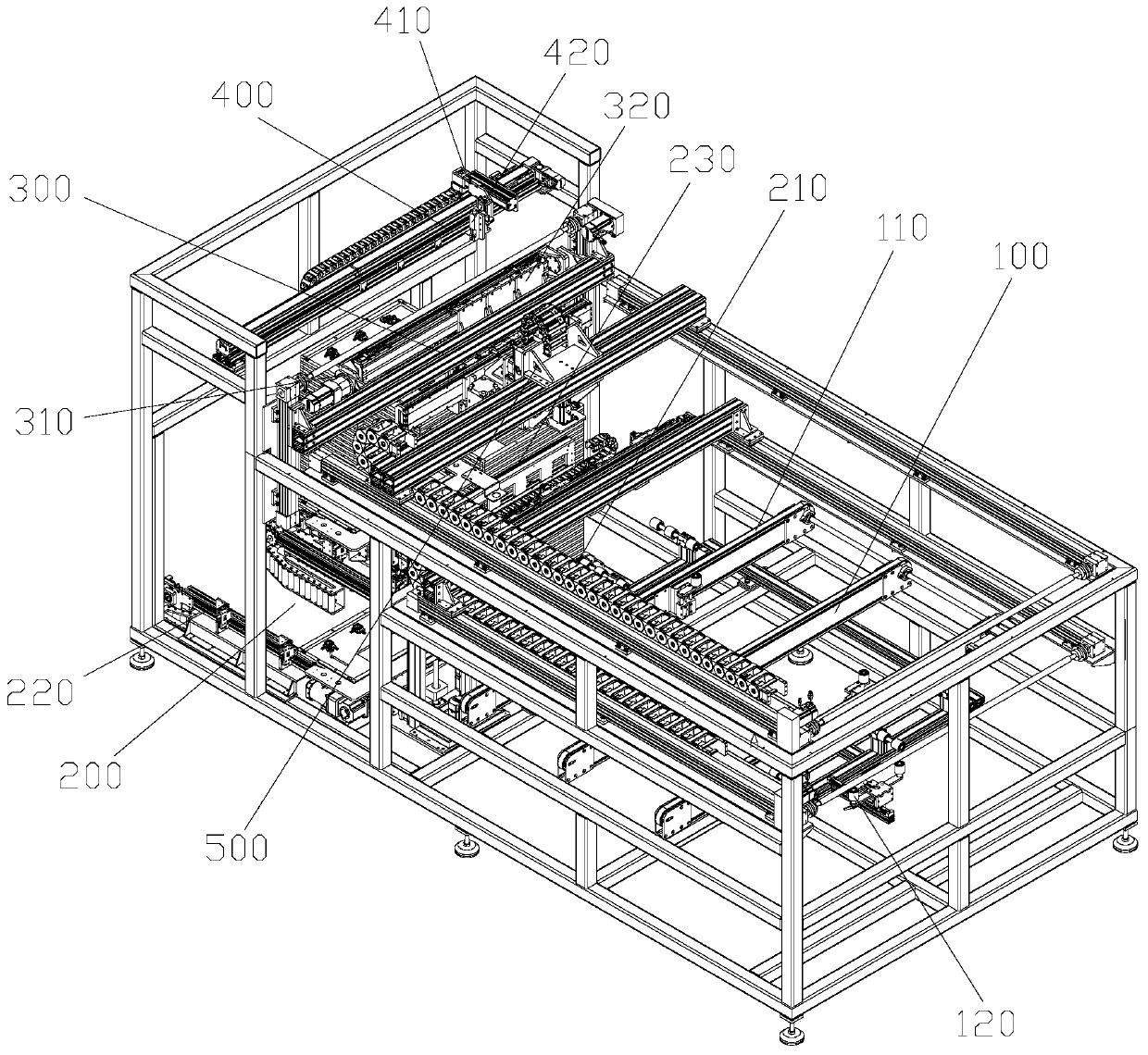

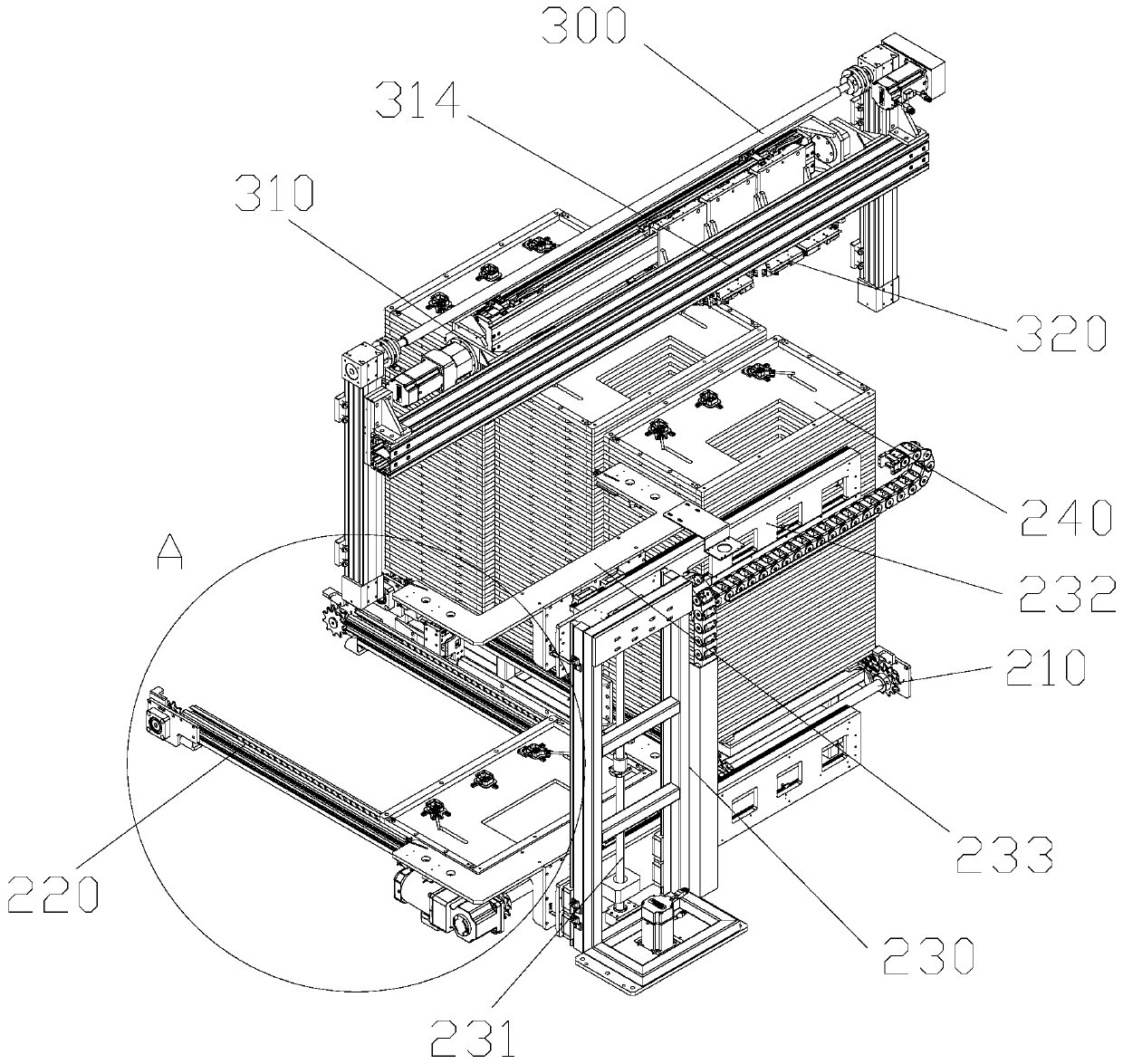

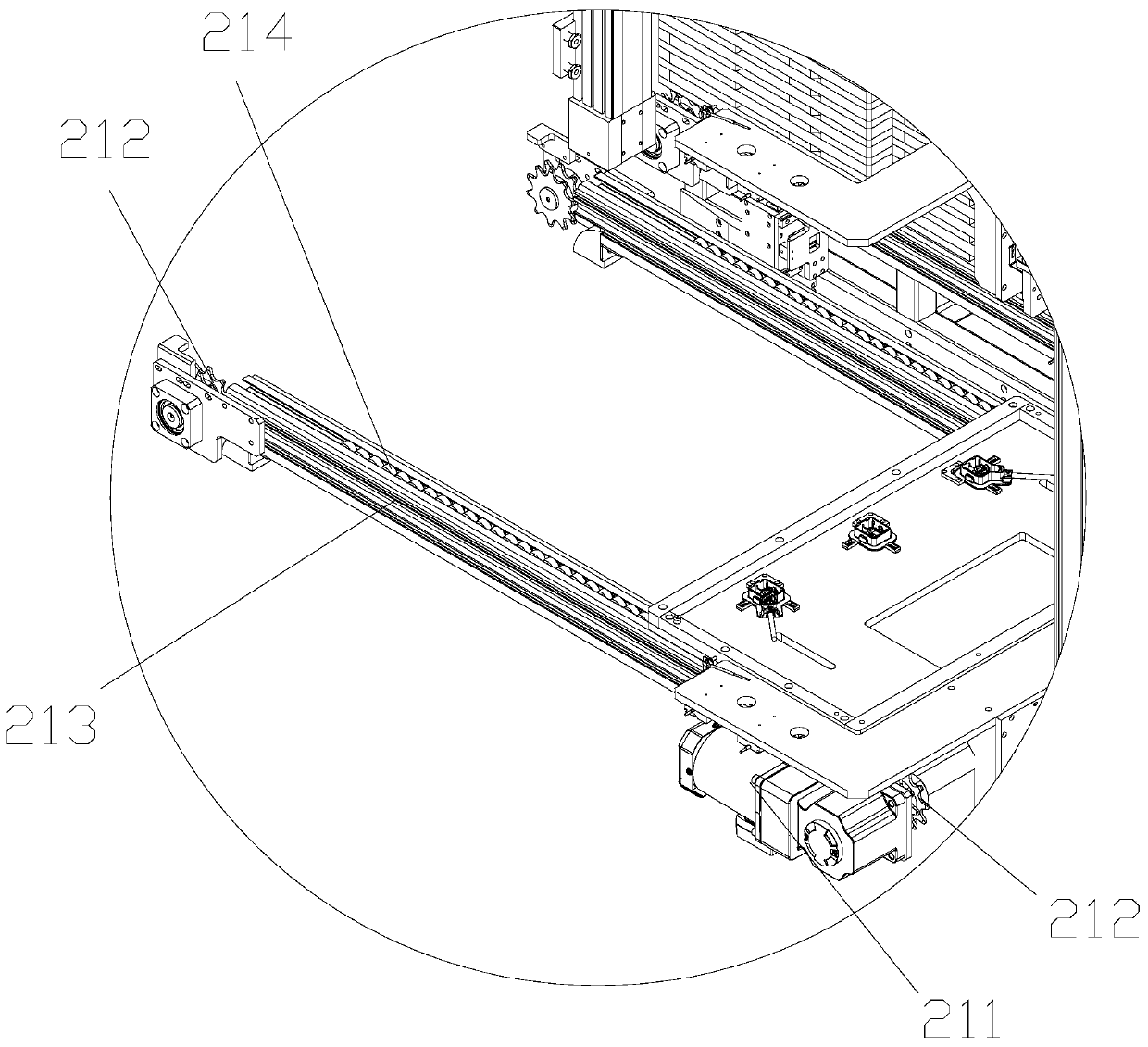

[0033] refer to Figure 1-Figure 10 As shown, it is a schematic diagram of an embodiment of a junction box shaping and assembling equipment of the present invention, including:

[0034] The conveying part 100, the conveying part 100 is provided with a conveying belt 110, and the two sides of the conveying belt 110 are provided with centering components 120. The photovoltaic module is conveyed to the bottom of the assembly part by the conveyor belt 110, and the blocking cylinder protrudes to prevent the photovoltaic module from continuing to be conveyed. The centering module 120 is pushed out from both sides to the middle, and the photovoltaic module is centered to ensure the accur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com