Automatic camshaft assembling machine

A technology for assembly machines and camshafts, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., and can solve problems such as low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

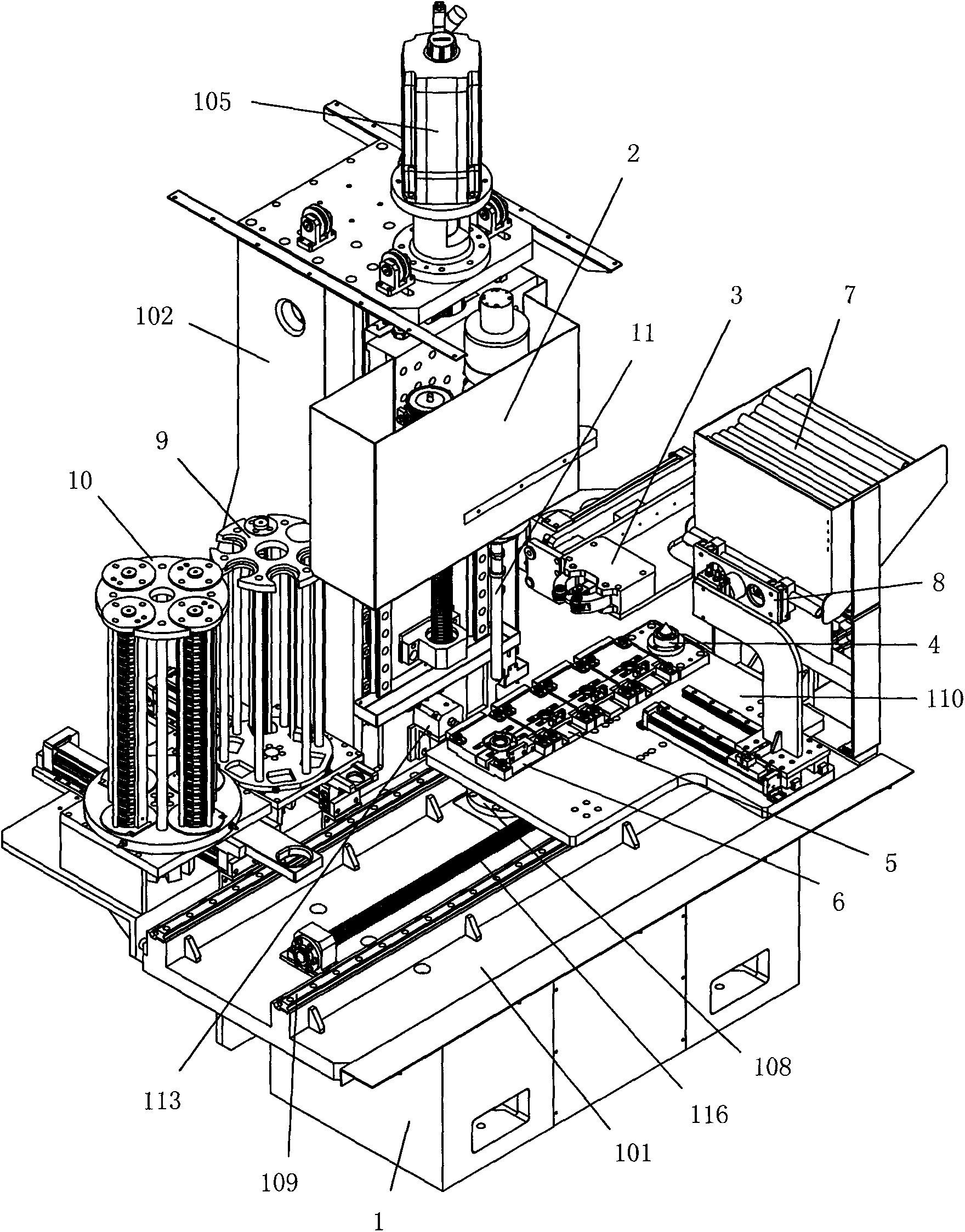

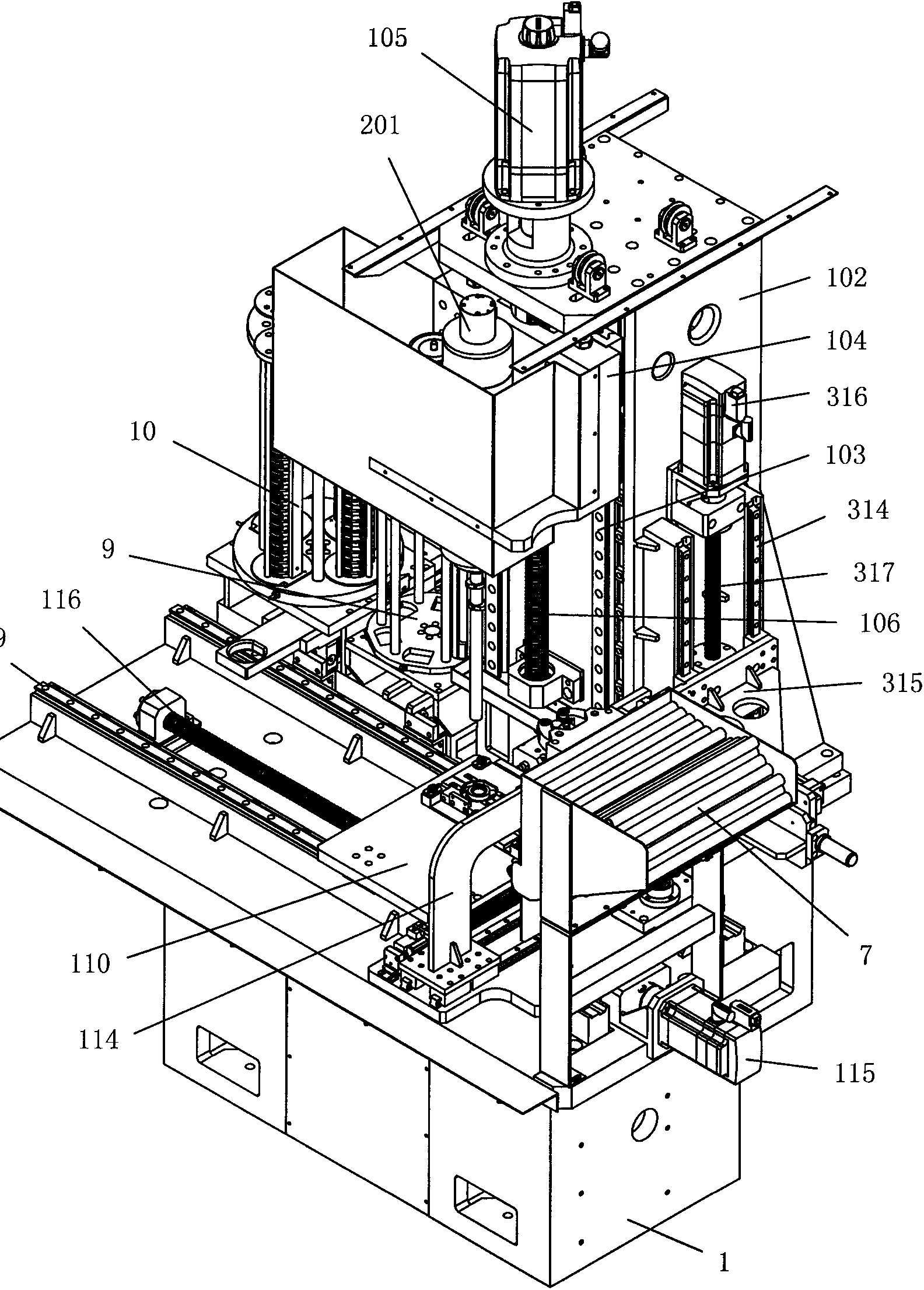

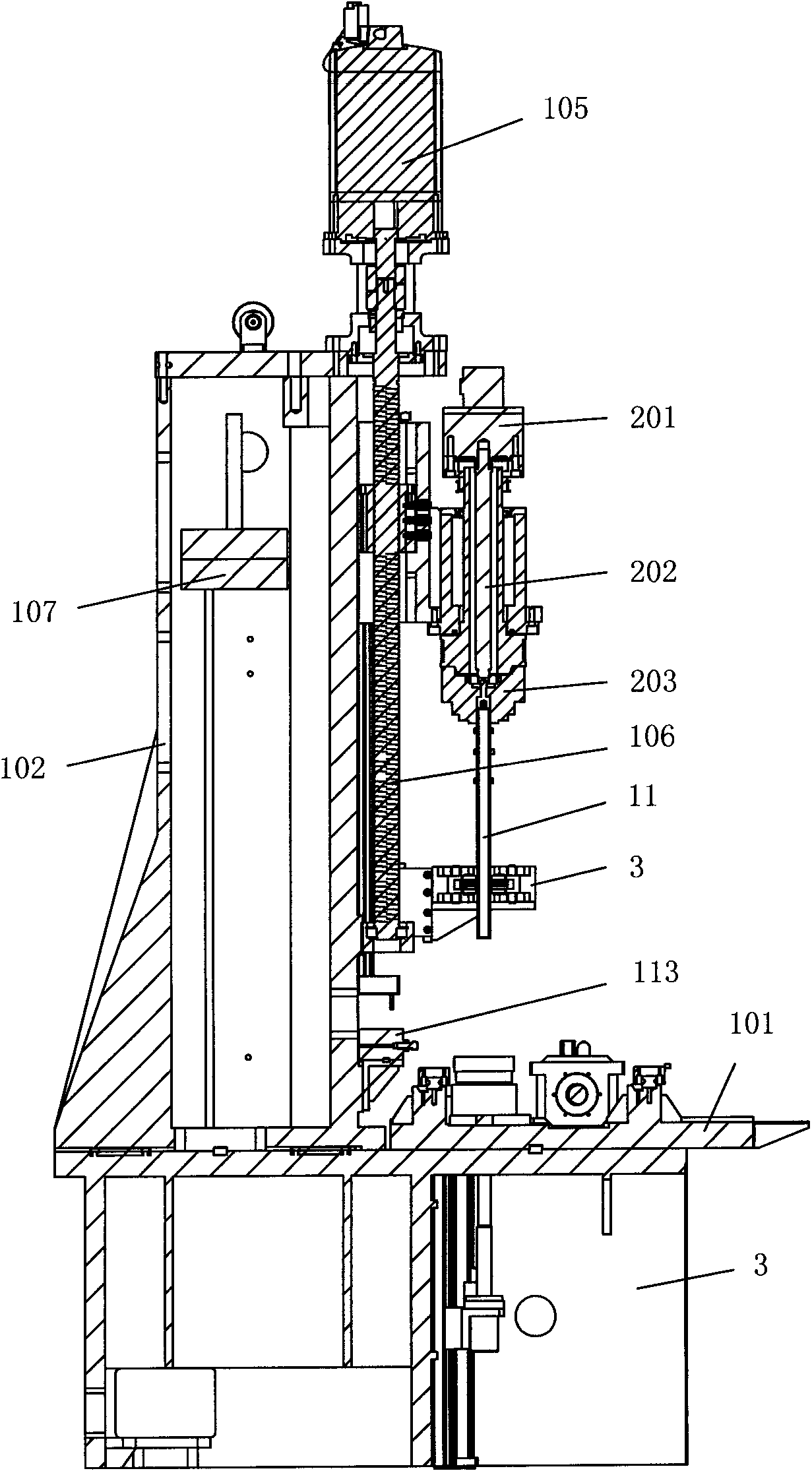

[0063] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0064] refer to Figure 1 to Figure 16 , an automatic assembly machine for camshafts, comprising a frame 1, a workbench 101 arranged on the frame 1, a column 102 is arranged on the workbench 1, and a column 102 for clamping pipe fittings is vertically slid on the column 102 And drive the clamping and rotating mechanism 2 that rotates the pipe fittings. The clamping and rotating mechanism 2 is driven by a vertical driving mechanism to move up and down relative to the column 102. The vertical driving mechanism includes a vertically arranged on the column 101 The vertical transfer guide rail 103, the vertical transfer guide rail 103 is slid with a vertical slide plate 104, the clamping rotation mechanism 2 is fixed on the vertical slide plate 104, and the upper end of the column 102 is provided with a vertical movement motor 105, the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com