Fire extinguisher head automatic assembling machine

A fire extinguisher and assembly machine technology, which is applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of inconsistent product quality specifications, high labor intensity of workers, low assembly efficiency, etc., to achieve convenient operation and improve automatic assembly speed. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

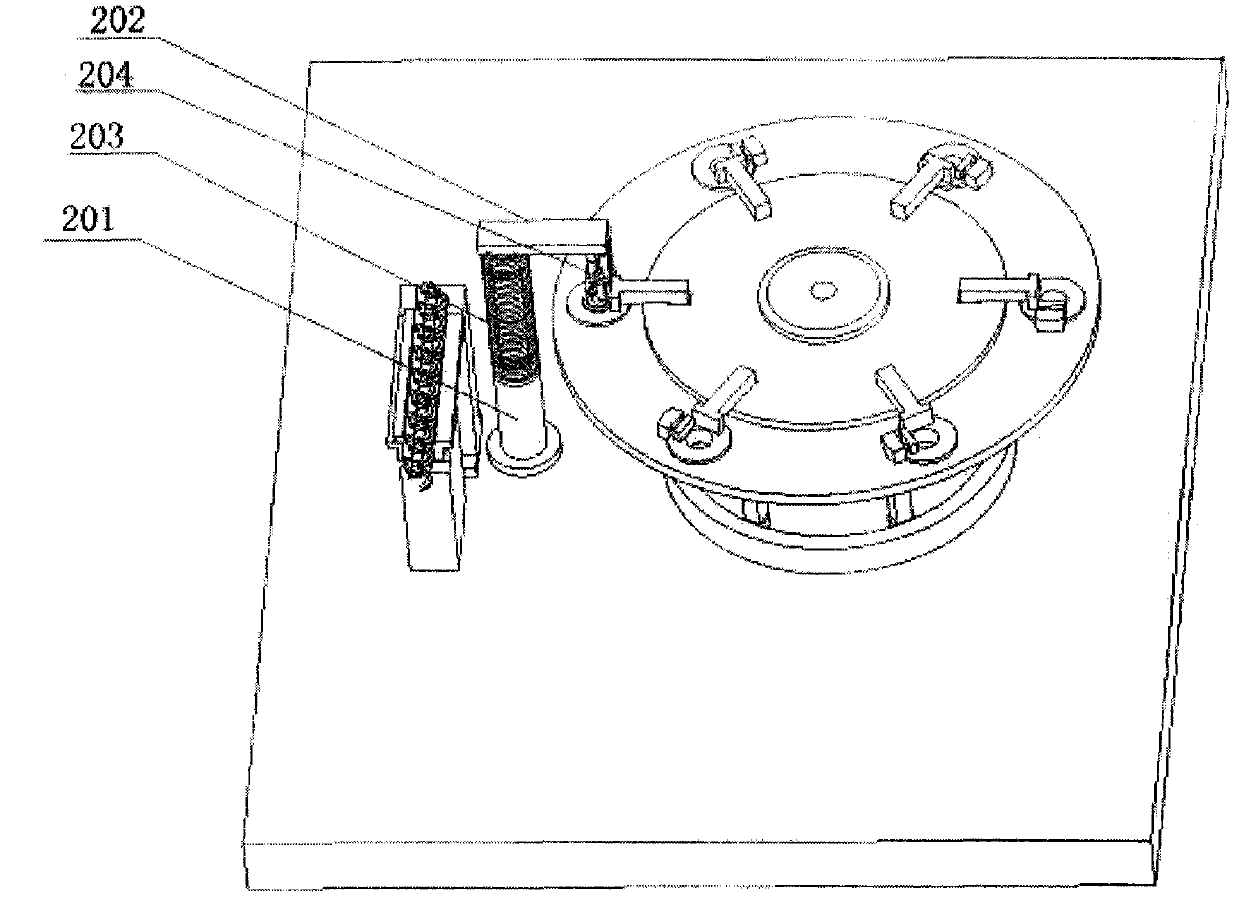

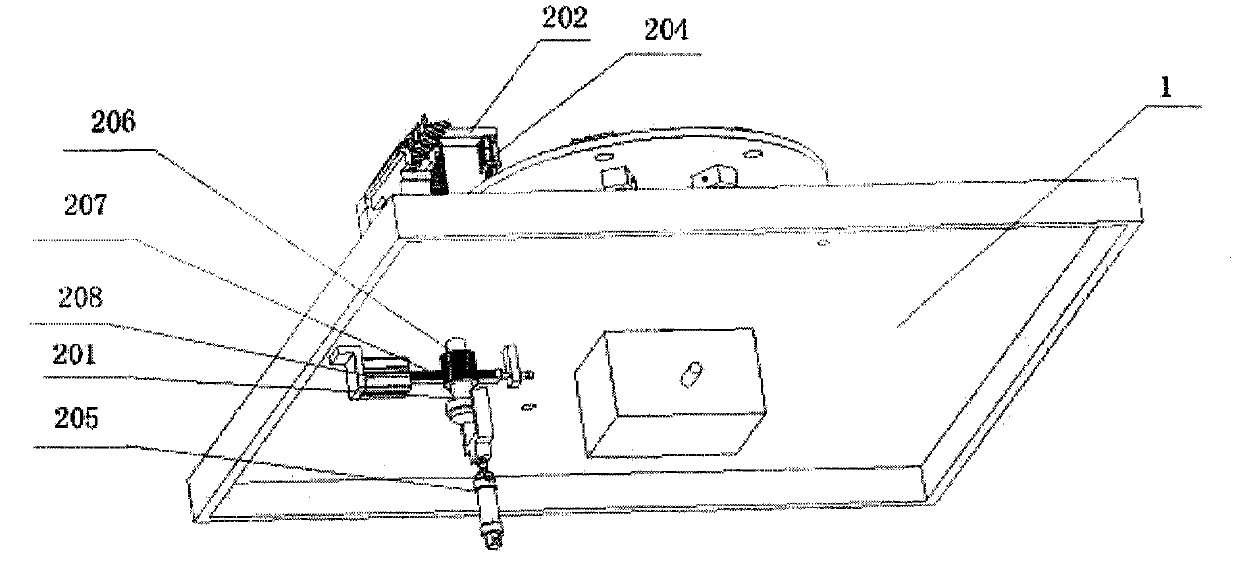

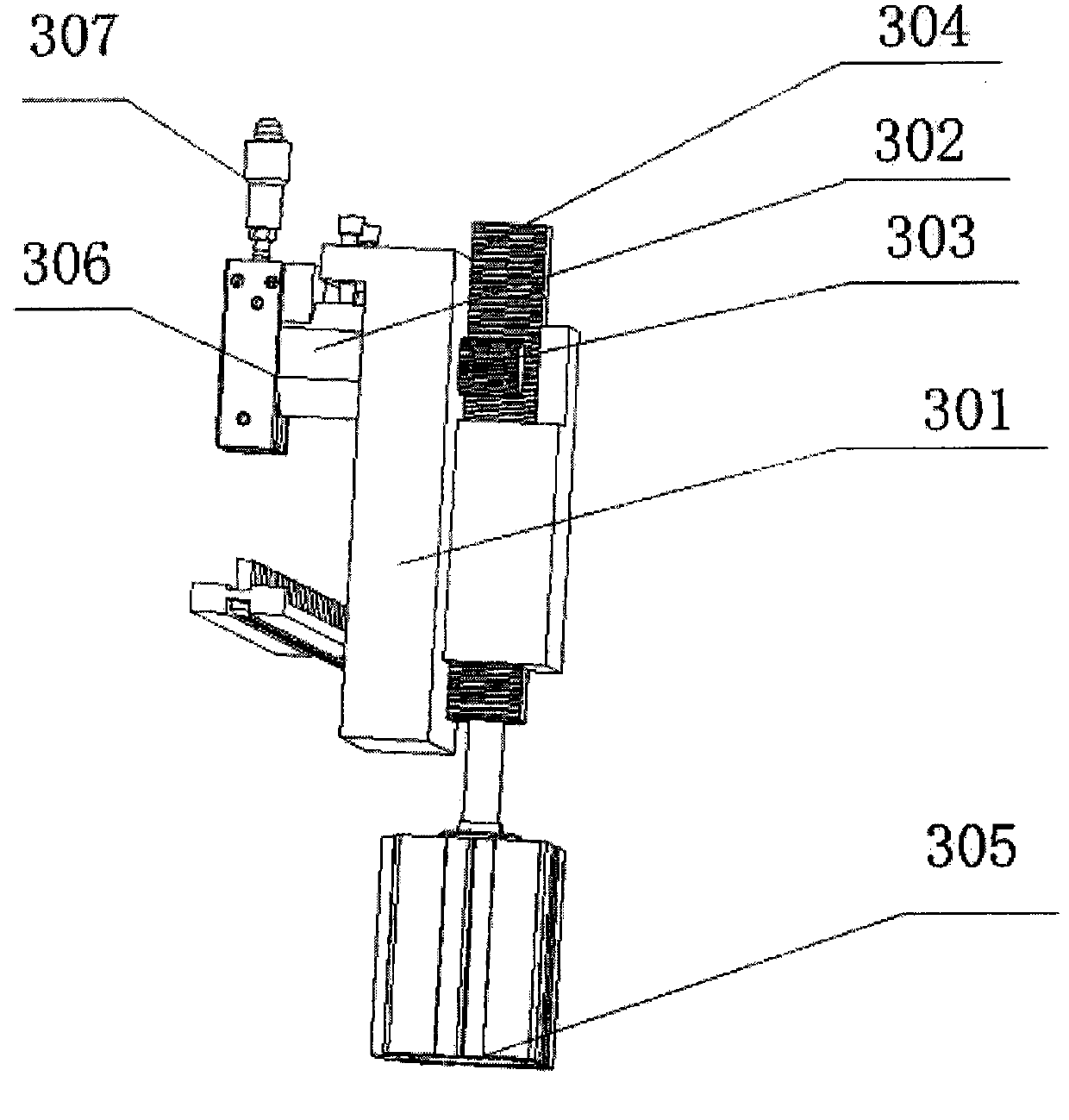

[0030] Such as figure 1 , figure 2 The shown fire extinguisher head automatic assembly machine includes a frame 1, a rotating disk 2 and a PLC control unit arranged on the frame 1, and a driving mechanism for driving the rotating disk 2 to rotate is arranged on the frame 1. The vibrating plate of the conveyor head element is set in turn on the periphery, and the head placement hole 3 is set on the rotating disk 2 in sequence. The pressing mechanism is equipped with an automatic feeding mechanism, a ejector rod installation mechanism, a spring and plastic joint installation mechanism, a handle pressing handle installation mechanism, an automatic riveting mechanism and an automatic unloading mechanism on the periphery of the rotating disk. The above-mentioned automatic feeding mechanism , The ejector rod installation mechanism, the spring and plastic joint installation mechanism, the handle and pressure handle installation mechanism, the automatic riveting mechanism and the au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com