Automatic assembly device of check rings for shafts

An automatic assembly device and shaft retaining ring technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, high cost, and time-consuming manual assembly, so as to improve the work safety factor, The effect of improving work efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

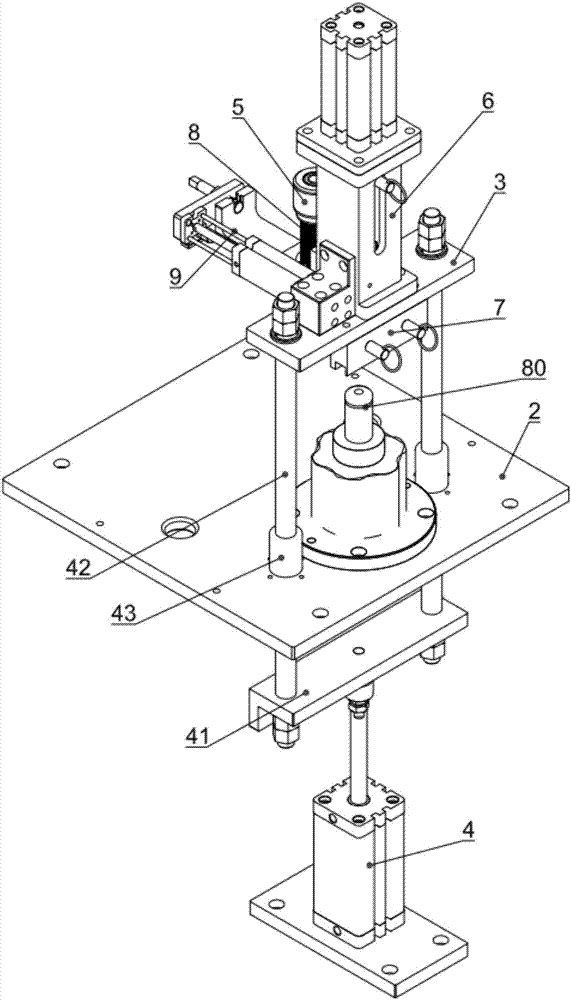

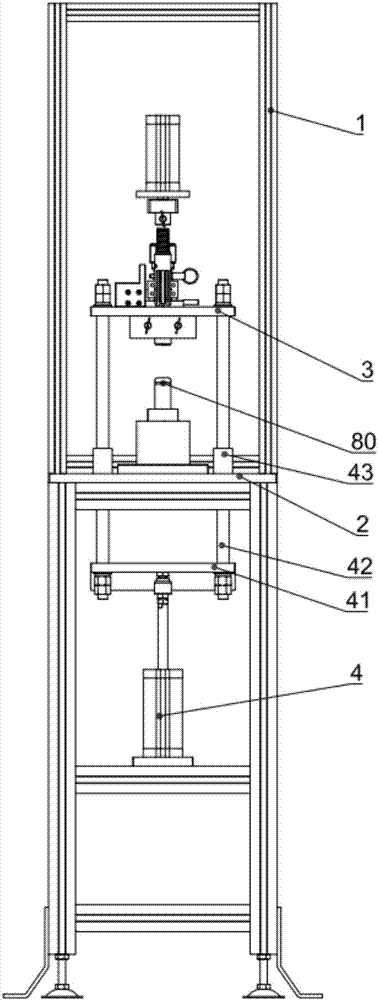

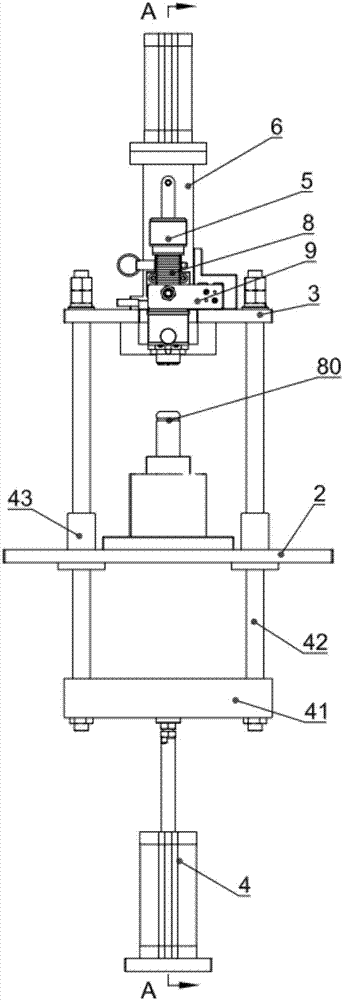

[0066] Such as Figure 1-4 and Figure 7 As shown, this embodiment provides an automatic assembly device for shaft retaining rings, such as figure 1 As shown, it includes a frame 1, and also includes a workbench 2, which is fixed on the frame 1 for placing parts to be assembled; a fixed plate 3, which is arranged above the workbench 2, and a conveying channel 31 is arranged on the fixed plate 3 ; The jacking cylinder 4 is fixed on the frame 1 and is located below the workbench 2. The extended end of the jacking cylinder 4 is connected to the fixing plate 3 for driving the fixing plate 3 to reciprocate relative to the workbench 2;

[0067] Such as Figure 5 and Figure 6 As shown, the storage unit 5 is set on the fixed plate 3, and the retaining ring 8 is set on the storage unit 5; the press-fit unit 6 is set on the fixed plate 3, and the guide unit 7 is arranged in turn below the press-fit unit 6 And retaining ring groove 80;

[0068] Such as Figure 7 and Figure 8 As ...

Embodiment 2

[0101] On the basis of the first embodiment above, the difference between this embodiment and the first embodiment is that the protruding end of the jacking cylinder 4 in the shaft retaining ring automatic assembly device in this embodiment is fixed on the workbench 2, The workbench 2 can reciprocate in a direction close to or away from the fixed plate 3 , and the fixed plate 3 , storage unit 5 , press-fit unit 6 , guide unit 7 and push unit 9 are fixed on the frame 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com