Laser welding technology of automobile power battery aluminum alloy shell

A technology for automobile power battery and aluminum alloy shell, which is applied in the field of laser welding technology of automobile power battery aluminum alloy shell, can solve the problems of low production efficiency, large linear expansion coefficient, increased heat input, etc., and achieves cost saving and tensile strength. Good, increase the effect of welding aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

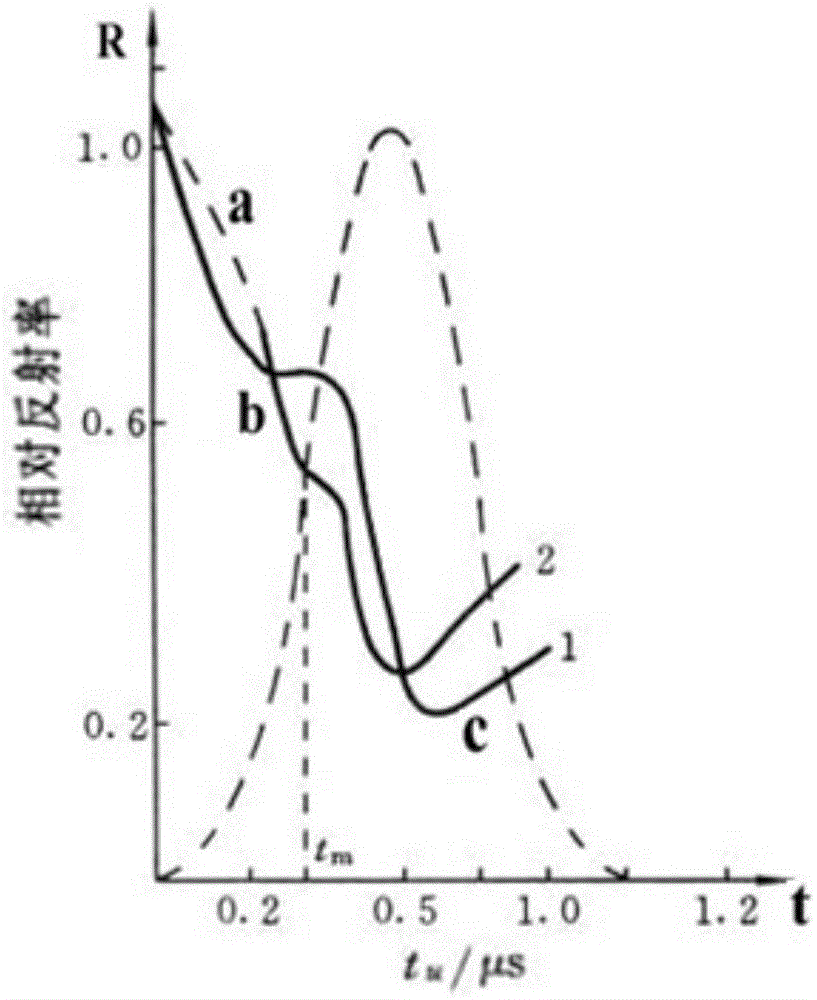

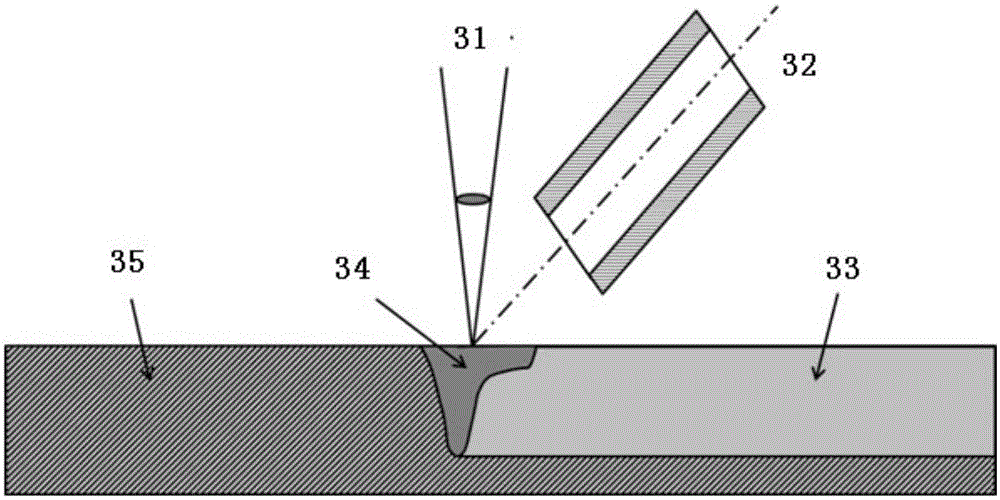

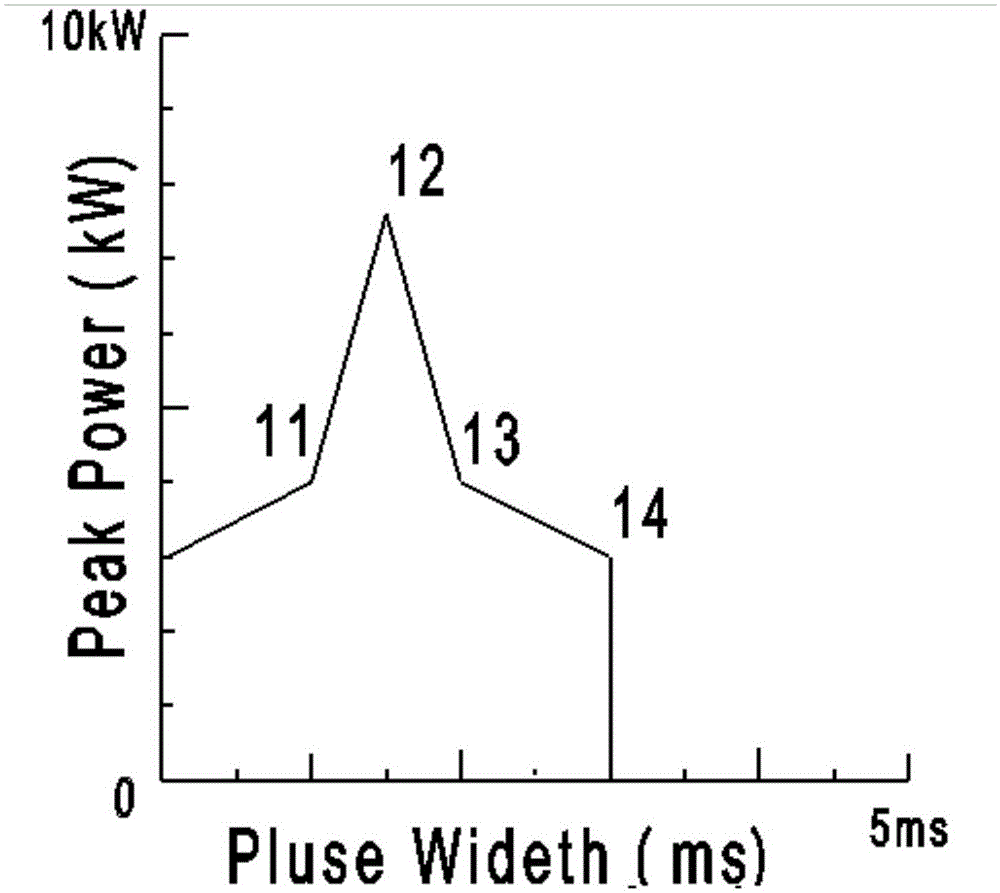

[0036] Such as figure 2 As shown, the workpiece 35 to be welded is a 1-series aluminum alloy with a thickness of 1.2mm, and a weld 33 is provided at the junction. The Nd:YAG solid-state pulse laser used for welding has a maximum power of 1000W and a peak power of 10KW. The minimum spot diameter is 0.6mm, the pulse width range is 1-10ms, the laser wavelength is 1.064μm, the laser power instability is ≤3%, and the focal length f of the focusing element is 80mm. The laser light emitted by the laser is transmitted by optical fiber and focused to the weld seam. The workpiece 35 to be welded moves in the horizontal plane and the laser beam 31 does not move so that the laser beam 31 scans the weld seam 33 at a speed of 2.1 mm / s to realize the workpiece 35 to be welded. of welding. During the welding process, an appropriate Ar gas flow is used to purge the welding melting pool 34 through the shielding gas nozzle 32 to protect the welding seam 33 from oxidation. The laser spot diame...

Embodiment 2

[0040] The workpiece 35 to be welded is a 3-series aluminum alloy with a thickness of 0.8 mm. The same laser welding equipment is used at the same welding speed. The main purpose of this example is to investigate the power selection in the preheating and heat preservation stages, which includes 6 specific implementations.

[0041] In this embodiment, the powers of preheating and heat preservation are the same, and its parameters are the same as those in Embodiment 1, the difference is that the power of preheating and heat preservation is adjusted within the range of 2-6KW, specifically, the power is 0-6KW. 1, 1~2, 2~3, 3~4, 4~5, 5~6kw, such as Figure 4 As shown, the red dot represents the final power, the abscissa is the power of preheating and heat preservation, and the ordinate is the result of the tensile strength test. The tensile strength data is tested according to the tensile test method of GB / T2652-1989 welding seam and deposited metal ( N / mm 2 ).

[0042] One of t...

Embodiment 3

[0048] This embodiment is a series 1 aluminum alloy with a thickness of 1.2mm. The same laser welding equipment is used at the same welding speed. The main purpose is to investigate the power selection in the heating stage, which includes 6 specific implementations, and its relevant experimental parameters are the same as in Example 1, and the difference is that the peak power in the heating stage is different. Such as Figure 5 and Figure 6 as shown, Figure 5 The weld depth data at 6, 6.5, 7, 7.5, 8, 8.5kw peak power are given in Figure 6 The weld width data at 6, 6.5, 7, 7.5, 8, 8.5kw peak power are given.

[0049] pass Figure 5 It can be seen that when the heating laser power is 6KW, due to the low energy, the sample is only a weld seam formed after a small amount of melting and solidification on the front side, which is not penetrated and uneven. With the increase of laser power, the weld seam morphology tends to be uniform, the weld width and penetration depth ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spot diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com