Distance and beam splitting energy adjustable three-light-spot laser welding optical system

A laser welding and optical system technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high price, limited optical fiber core diameter difference, and difficult processing of mirror surface, so as to improve the quality of weld seam and structural design Novelty, the effect of meeting the needs of processing in all directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

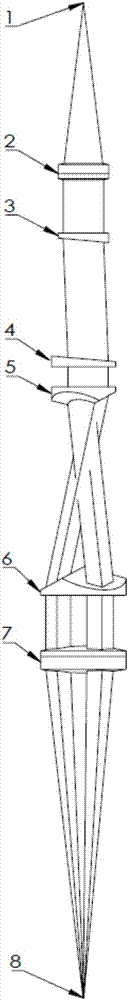

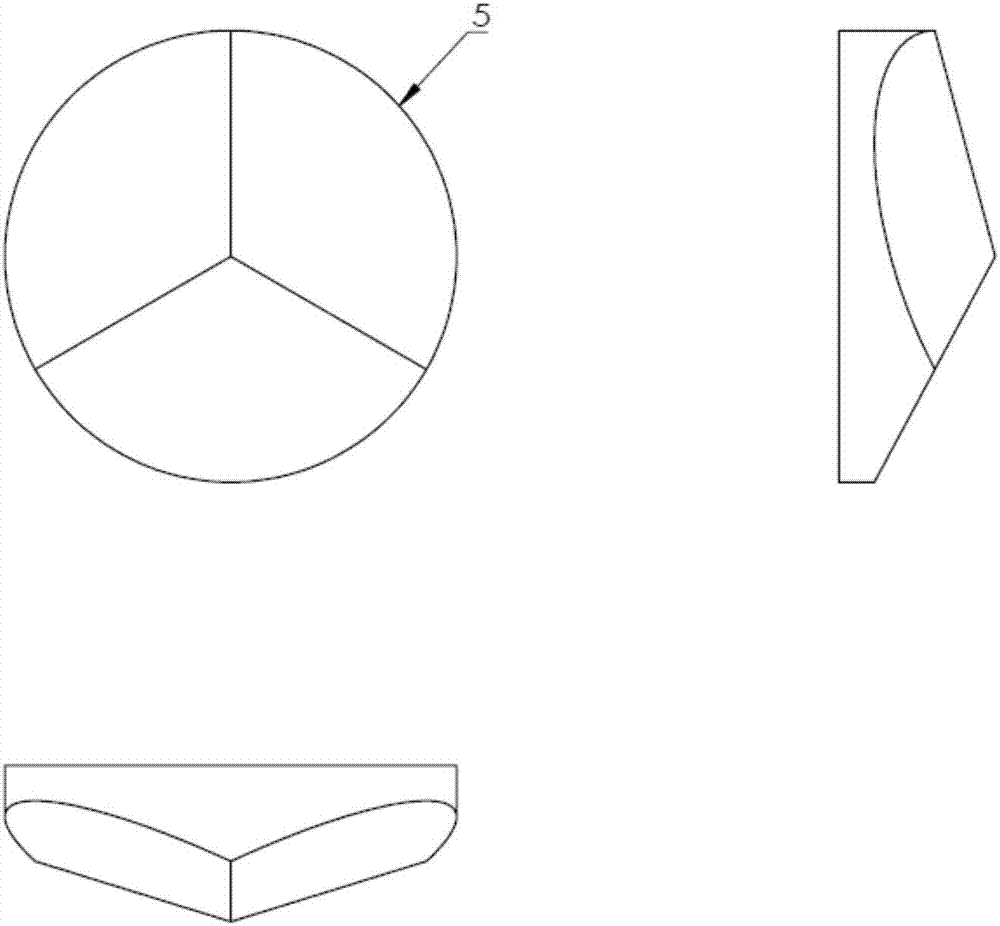

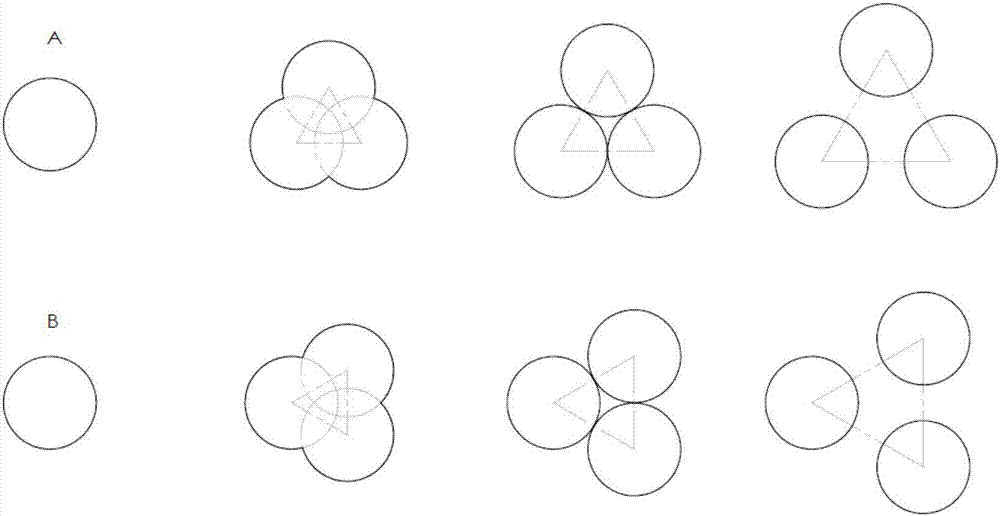

[0021] Such as figure 1 , figure 2 and image 3 As shown, this specific embodiment adopts the following technical solution: a three-spot laser welding optical system with adjustable spacing and splitting energy, including: fiber laser self-exit point 1 and focal plane 8, and also includes aberration-eliminating collimating lens group 2 , the first circular wedge mirror 3, the second circular wedge mirror 4, the first three-beam splitting prism 5, the second three-beam splitting prism 6 and the aberration-elimination focusing lens group 7; 1. Aberration-eliminating collimating lens group 2. The first circular wedge mirror 3. The second circular wedge mirror 4. The first three-beam splitting prism 5. The second three-beam splitting prism 6. Aberration-eliminating focusing mirror The group 7 and the focal plane 8 are arranged in a spaced manner from top to bottom and are concentric with each other; the first circular wedge mirror 3 and the second circular wedge mirror 4 are pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com